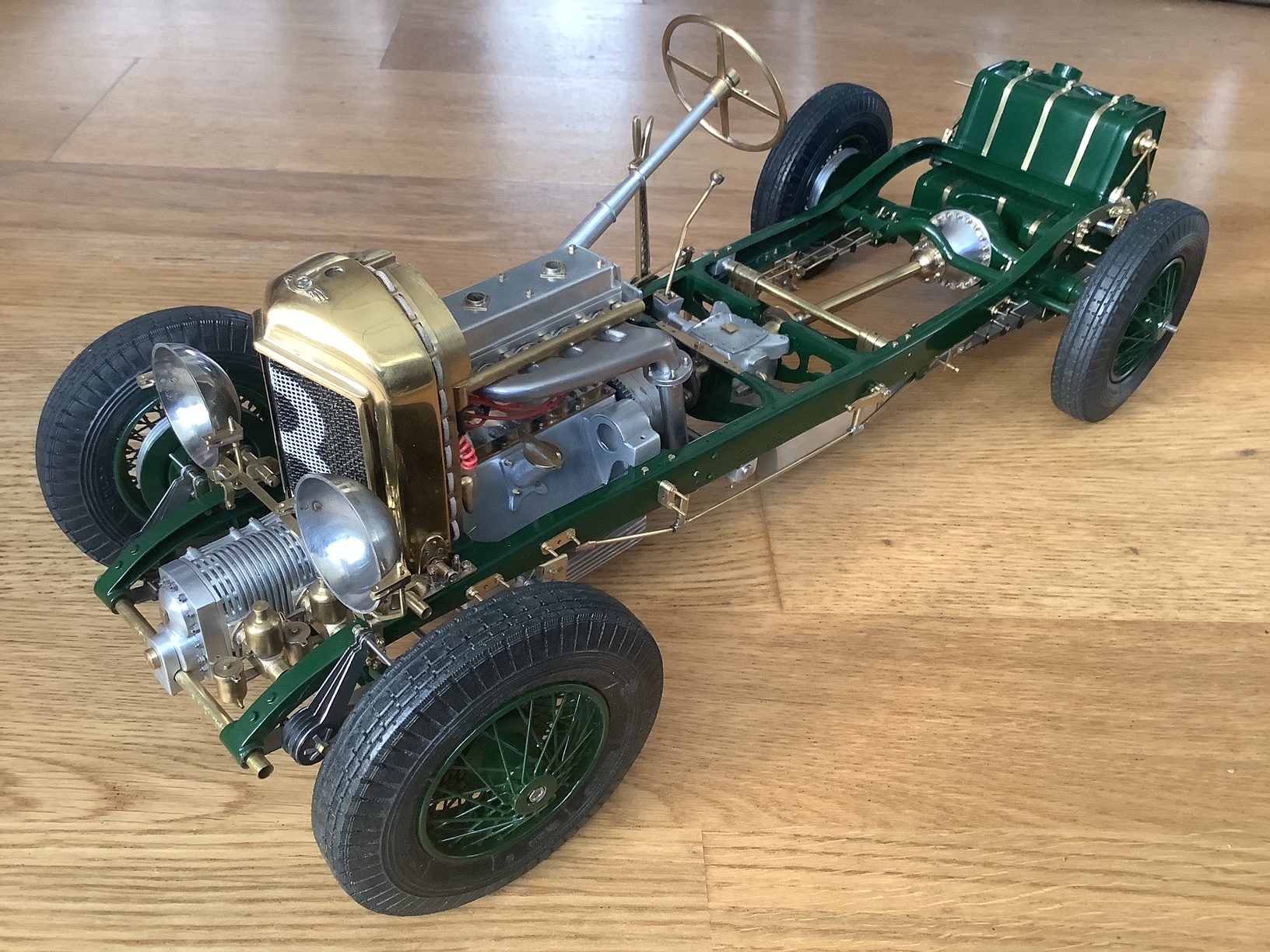

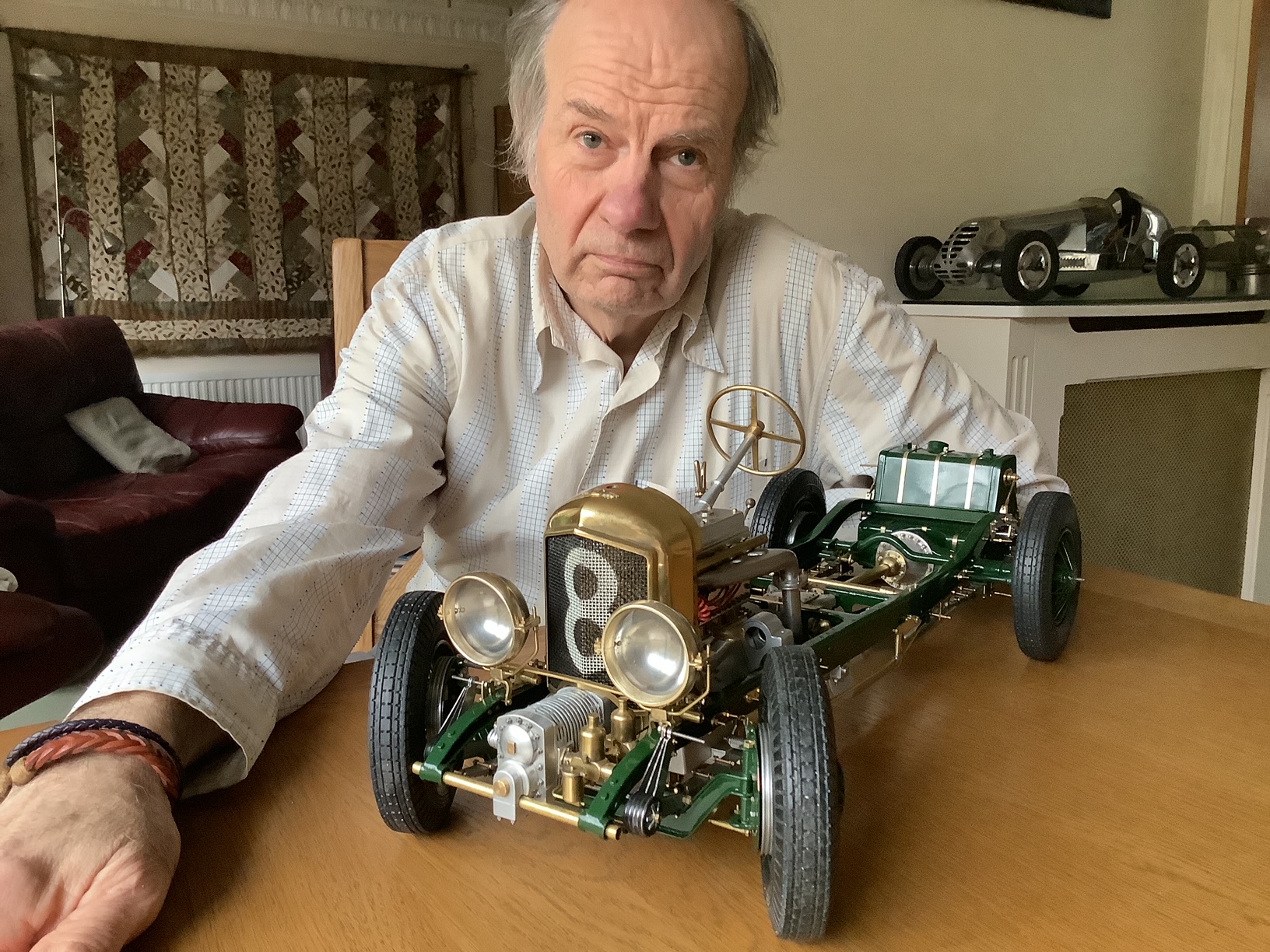

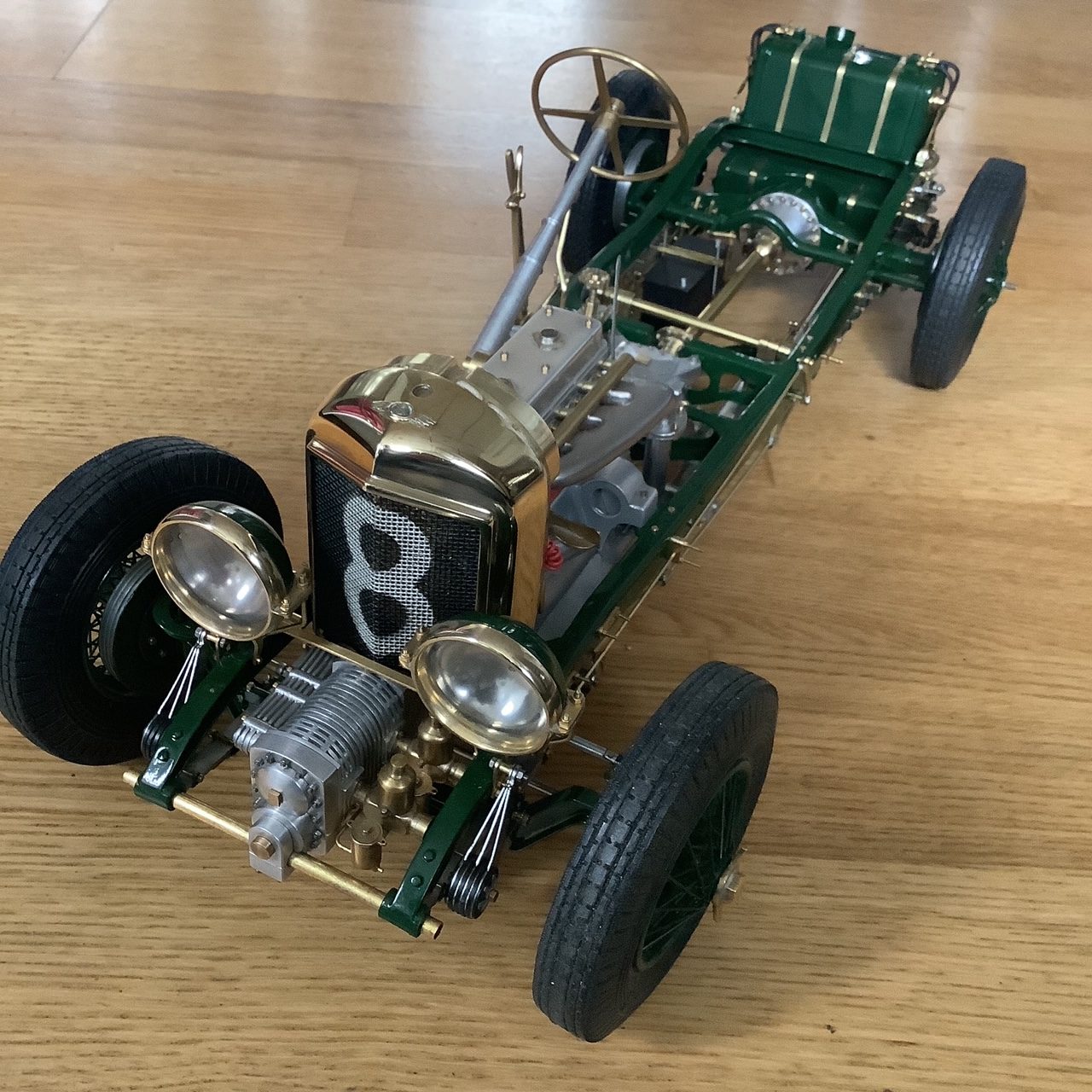

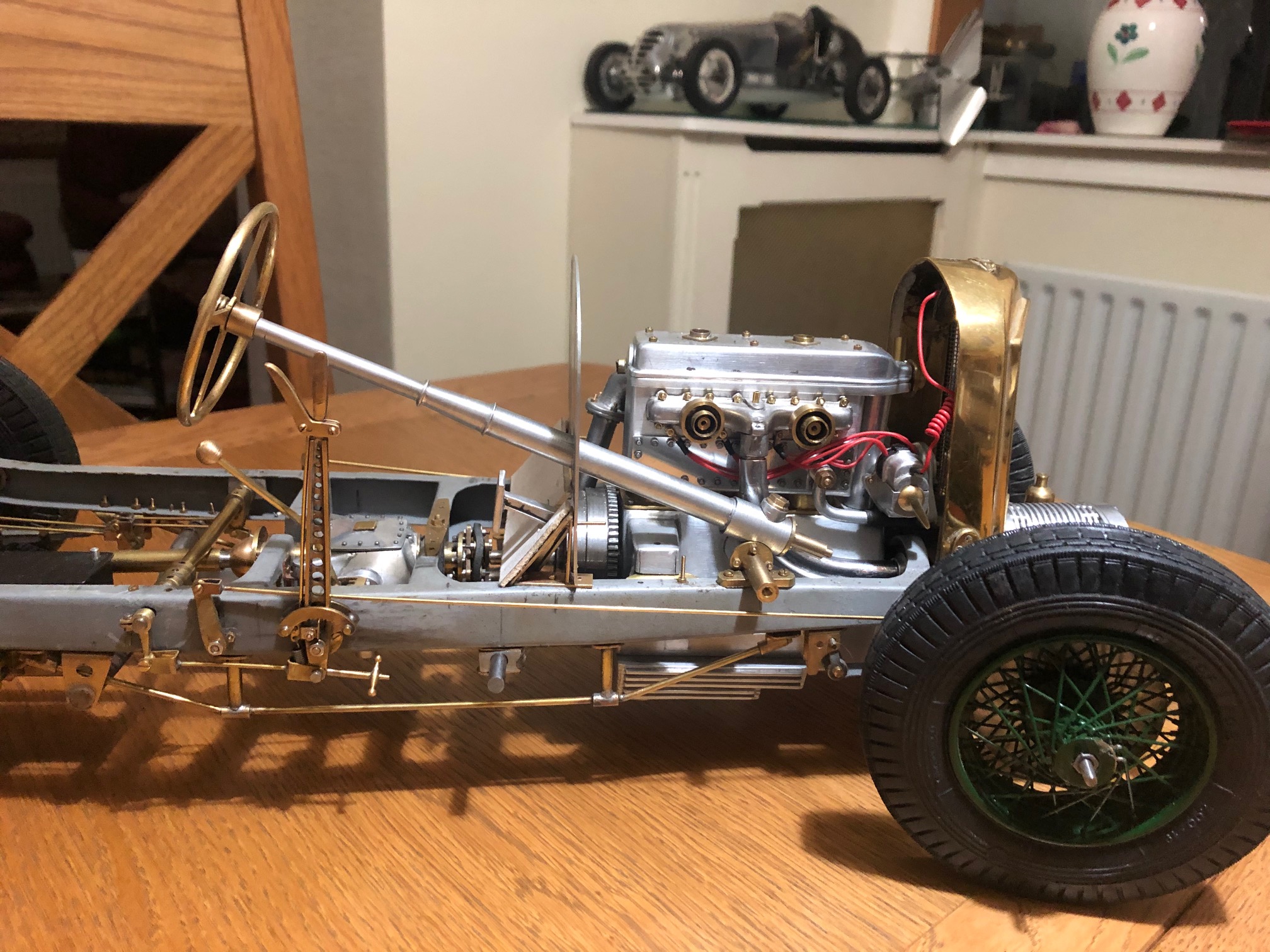

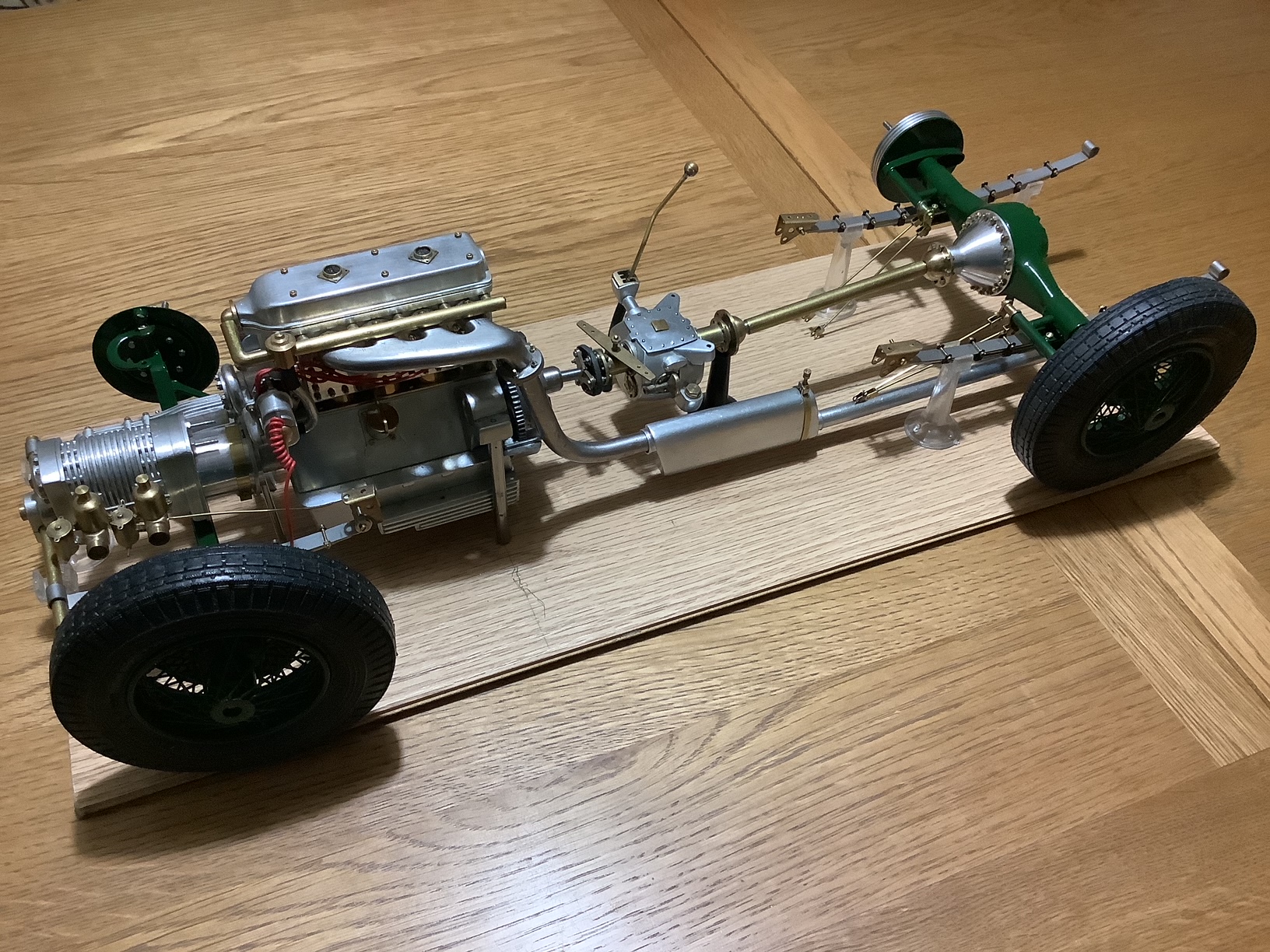

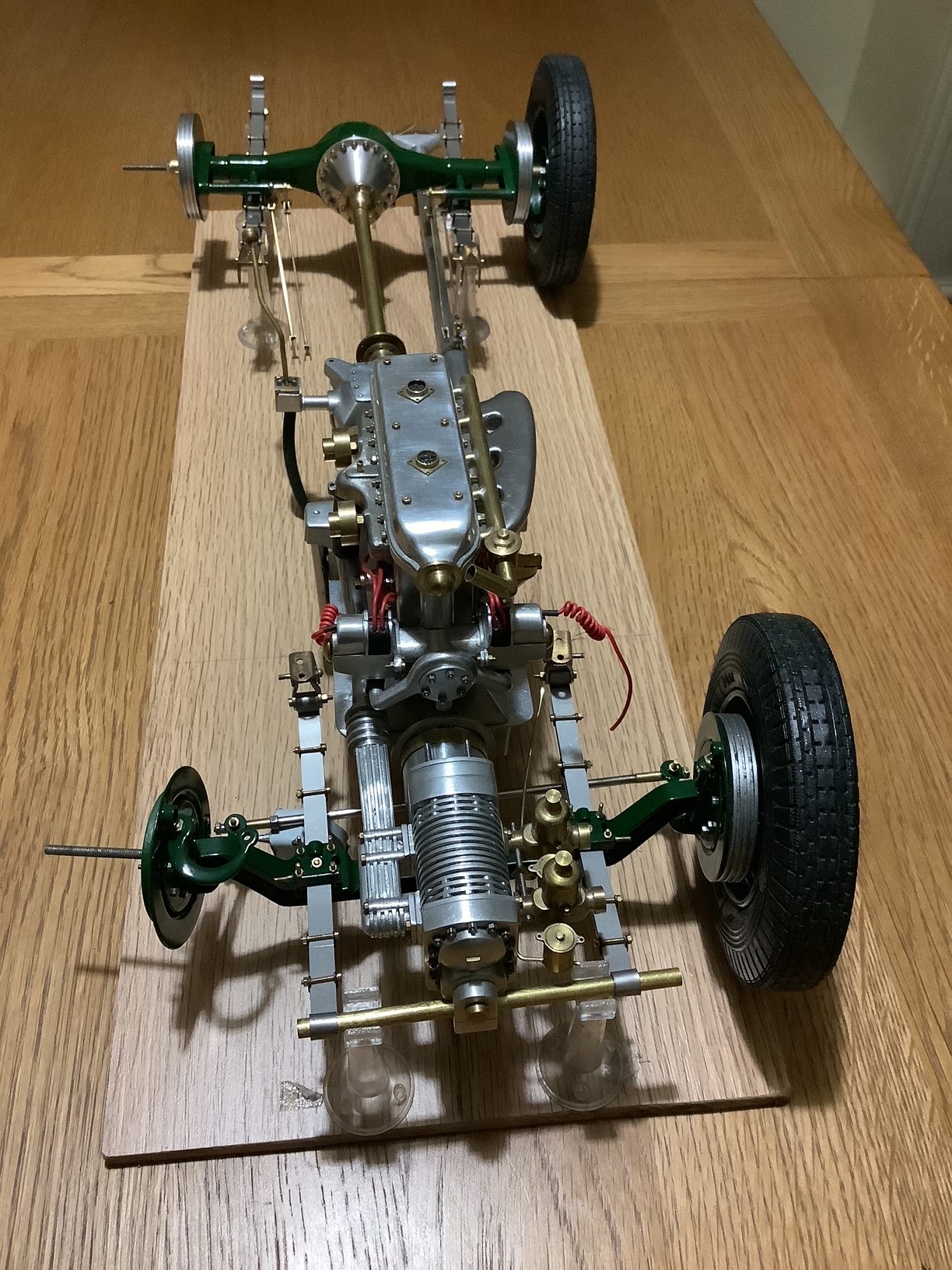

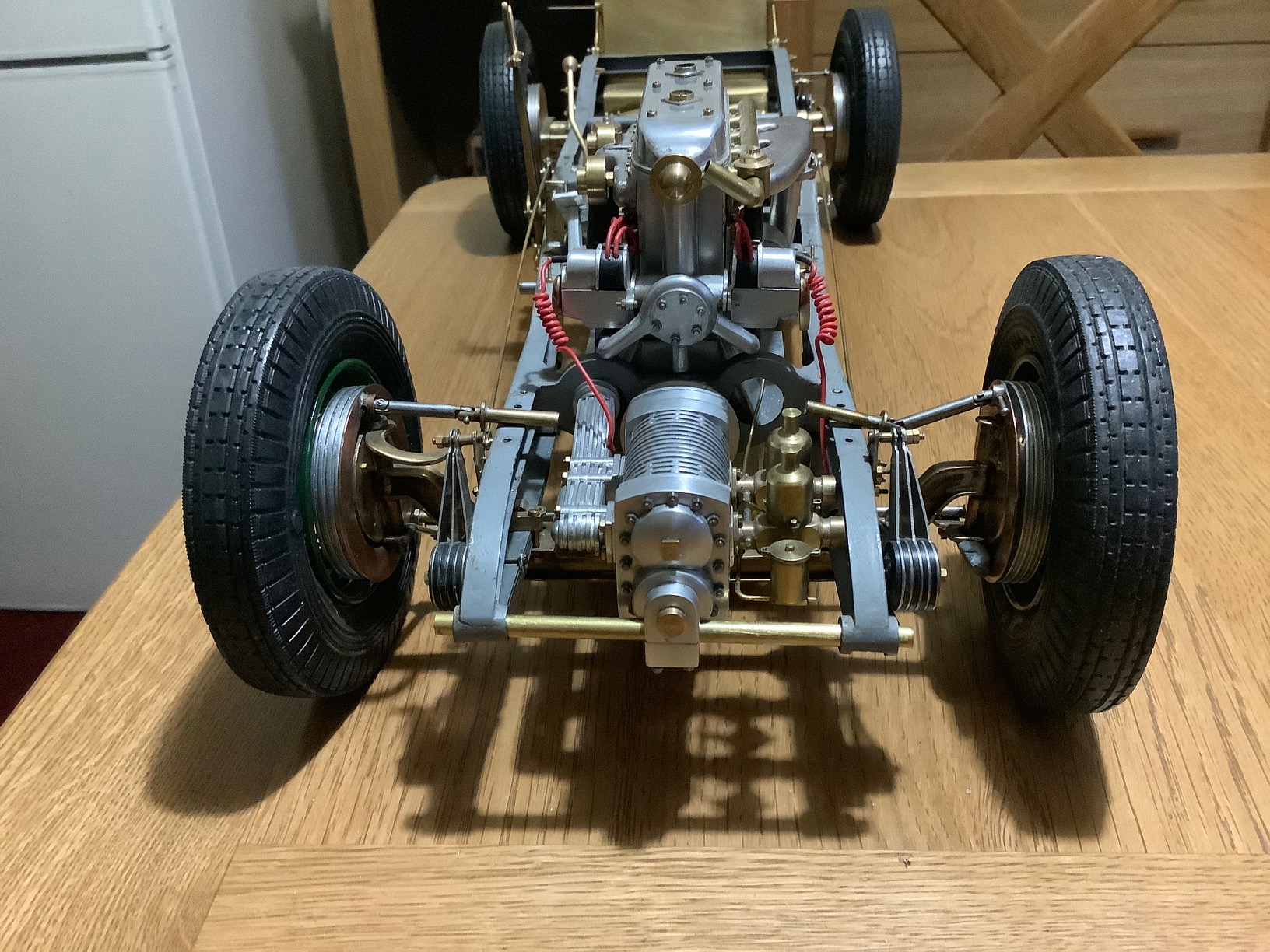

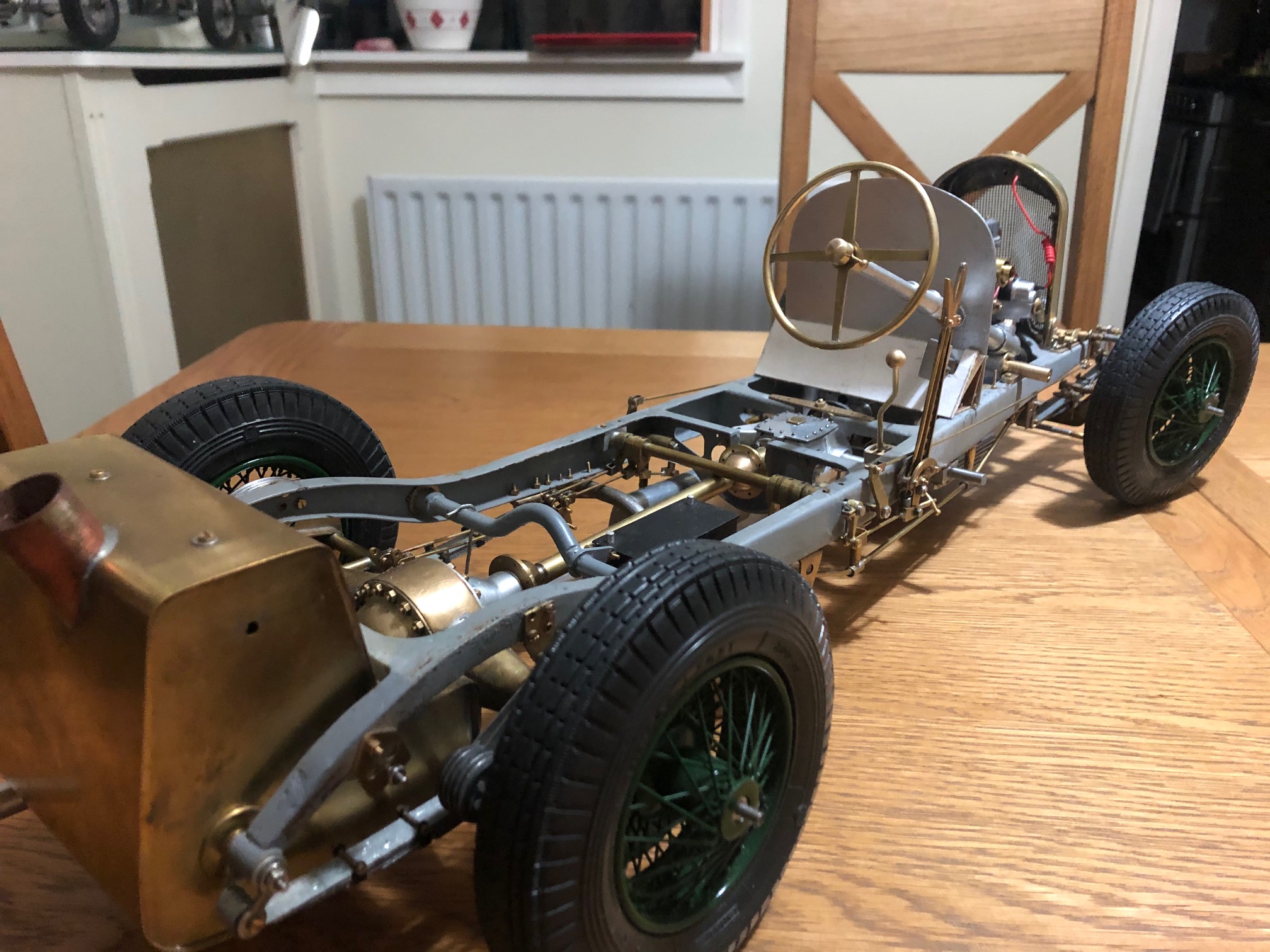

Keith Dungworth's

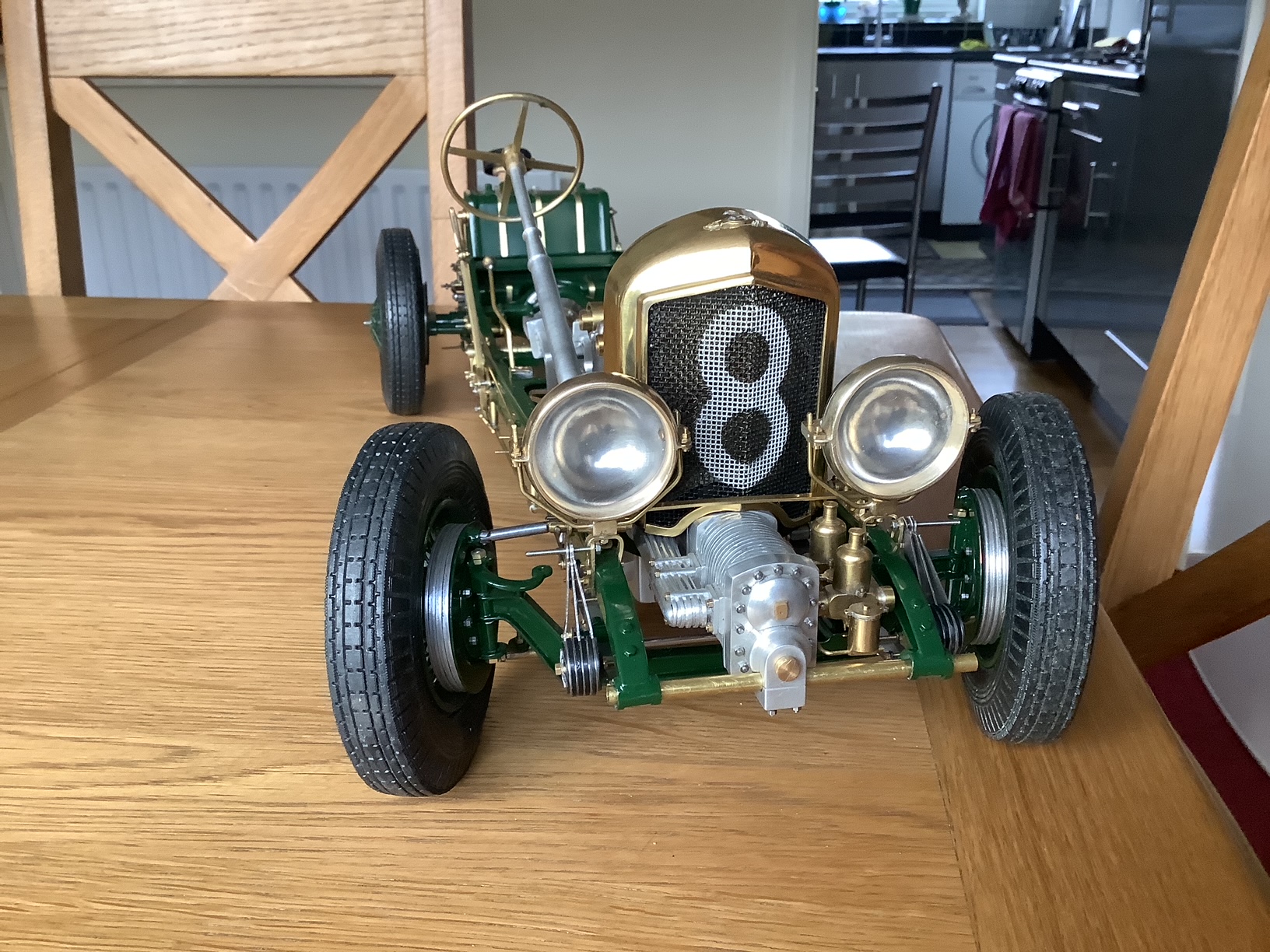

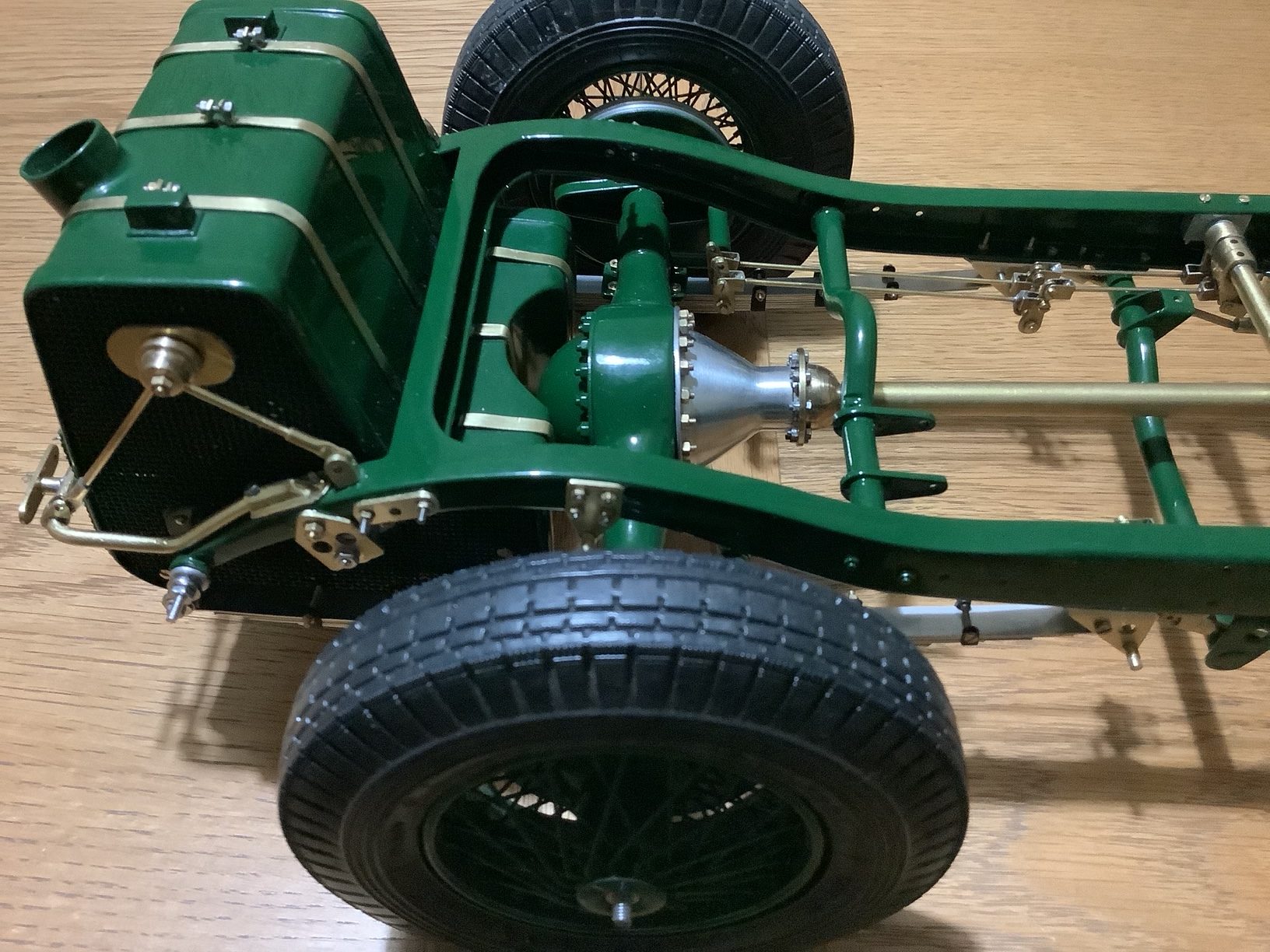

1929 Bentley 4.5 litre Blower

From the Builder...

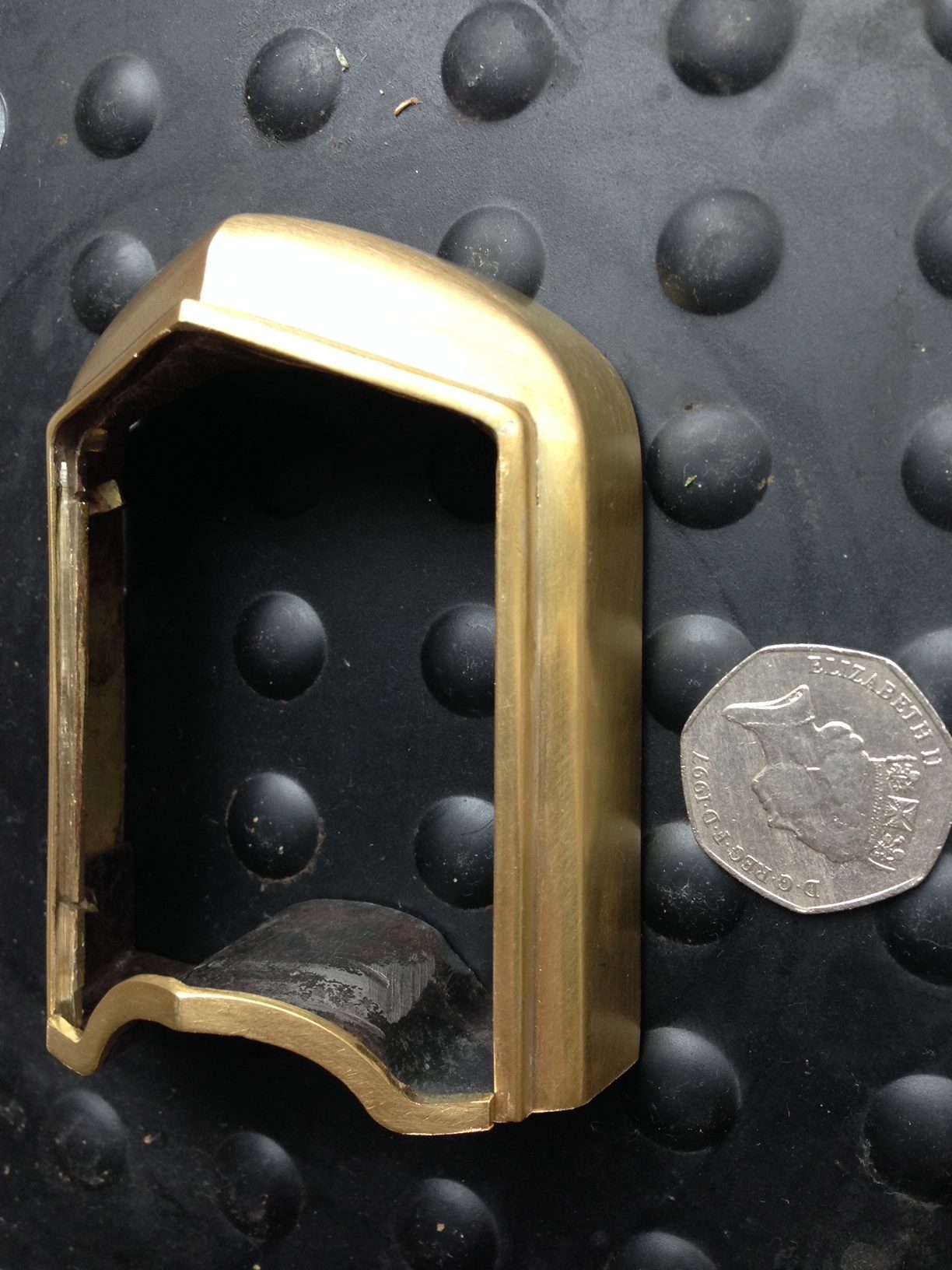

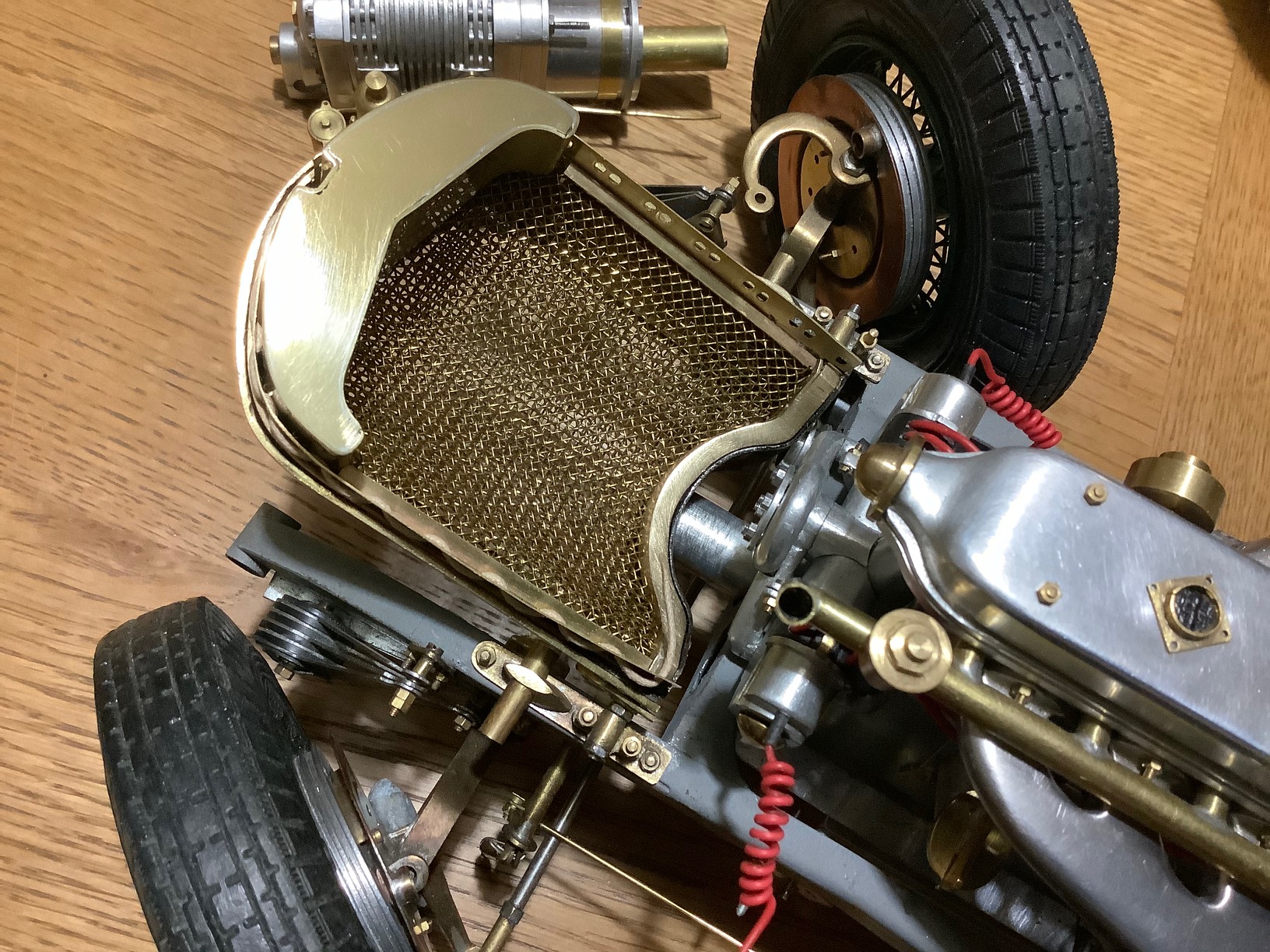

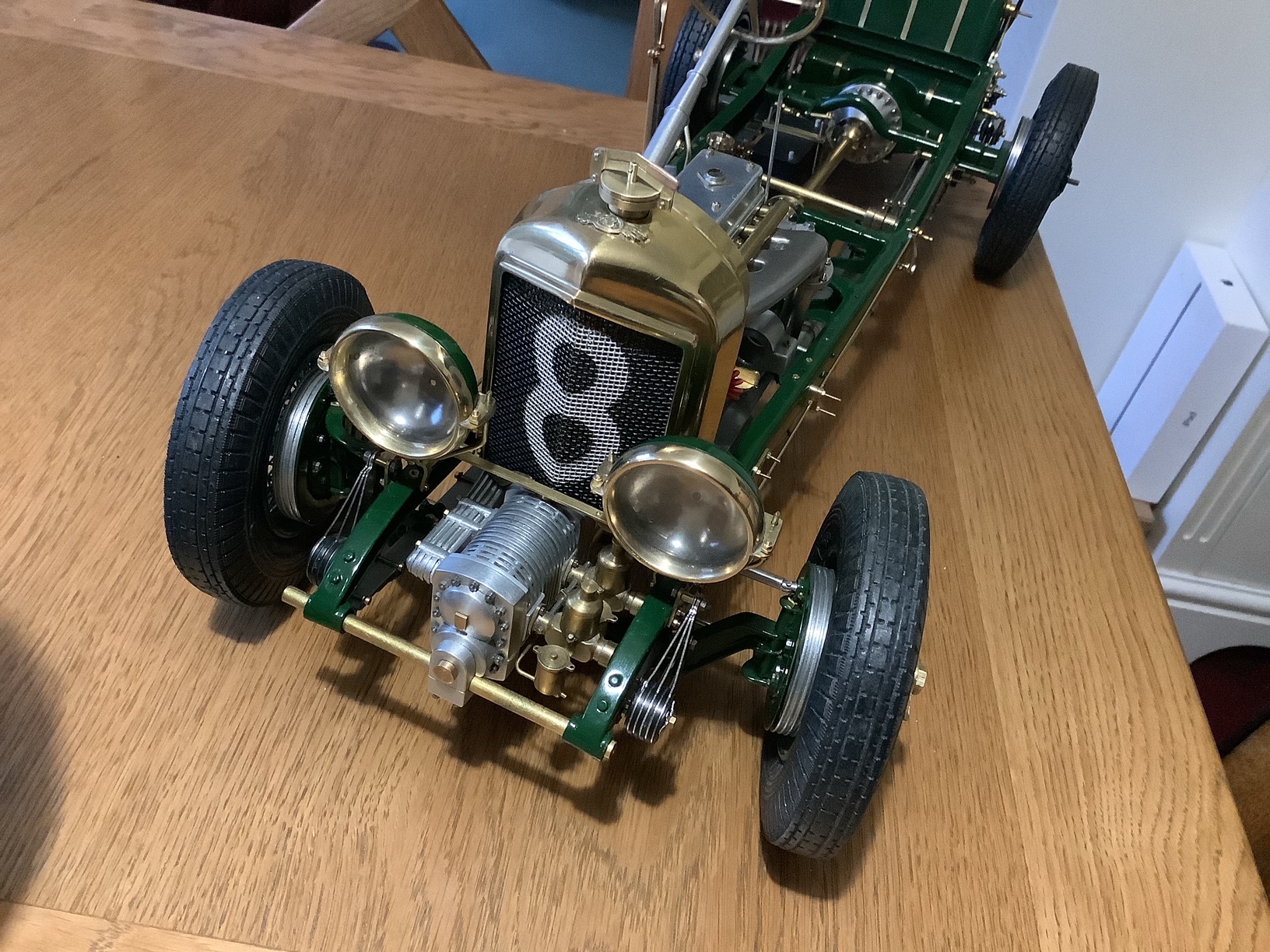

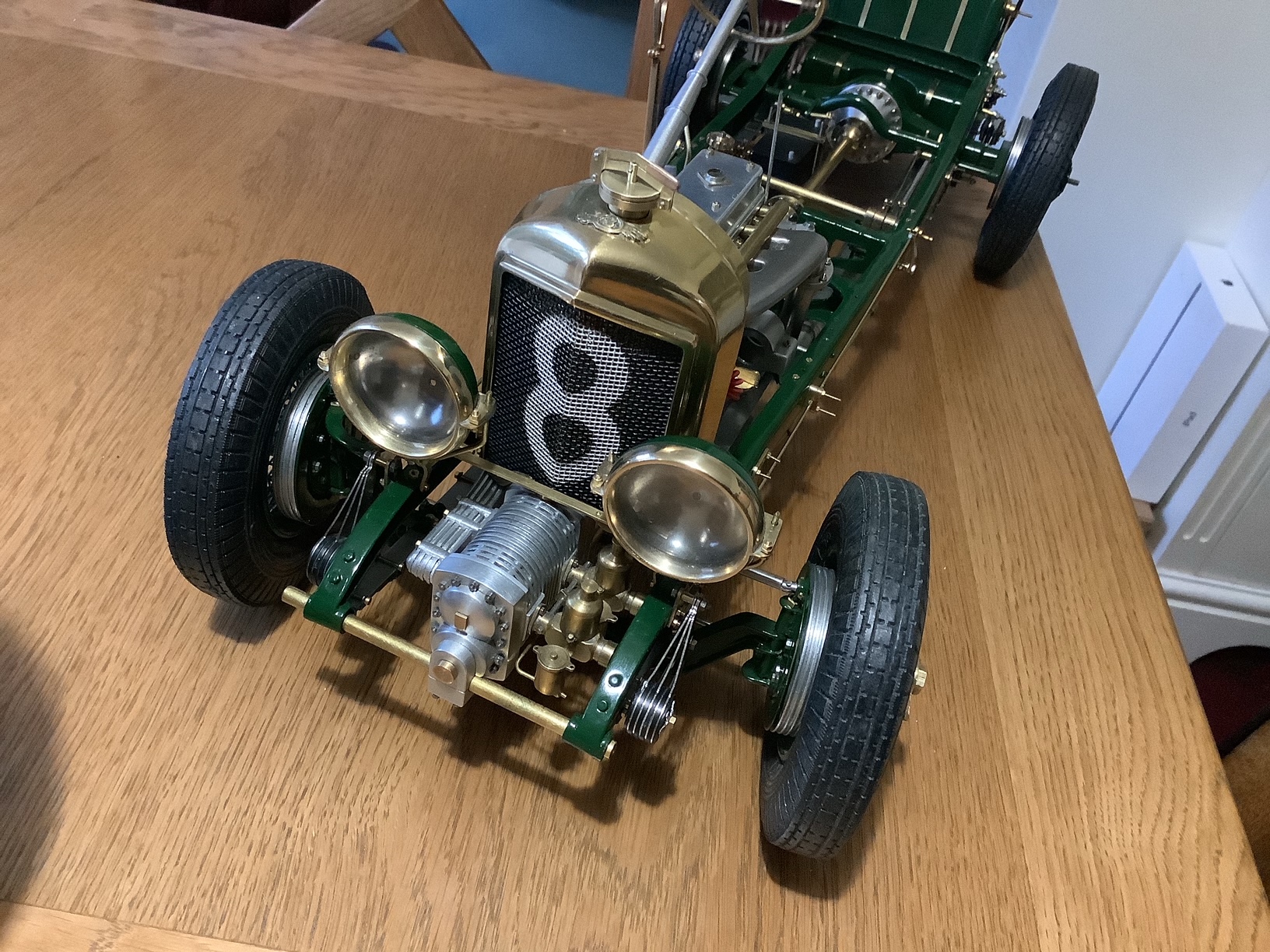

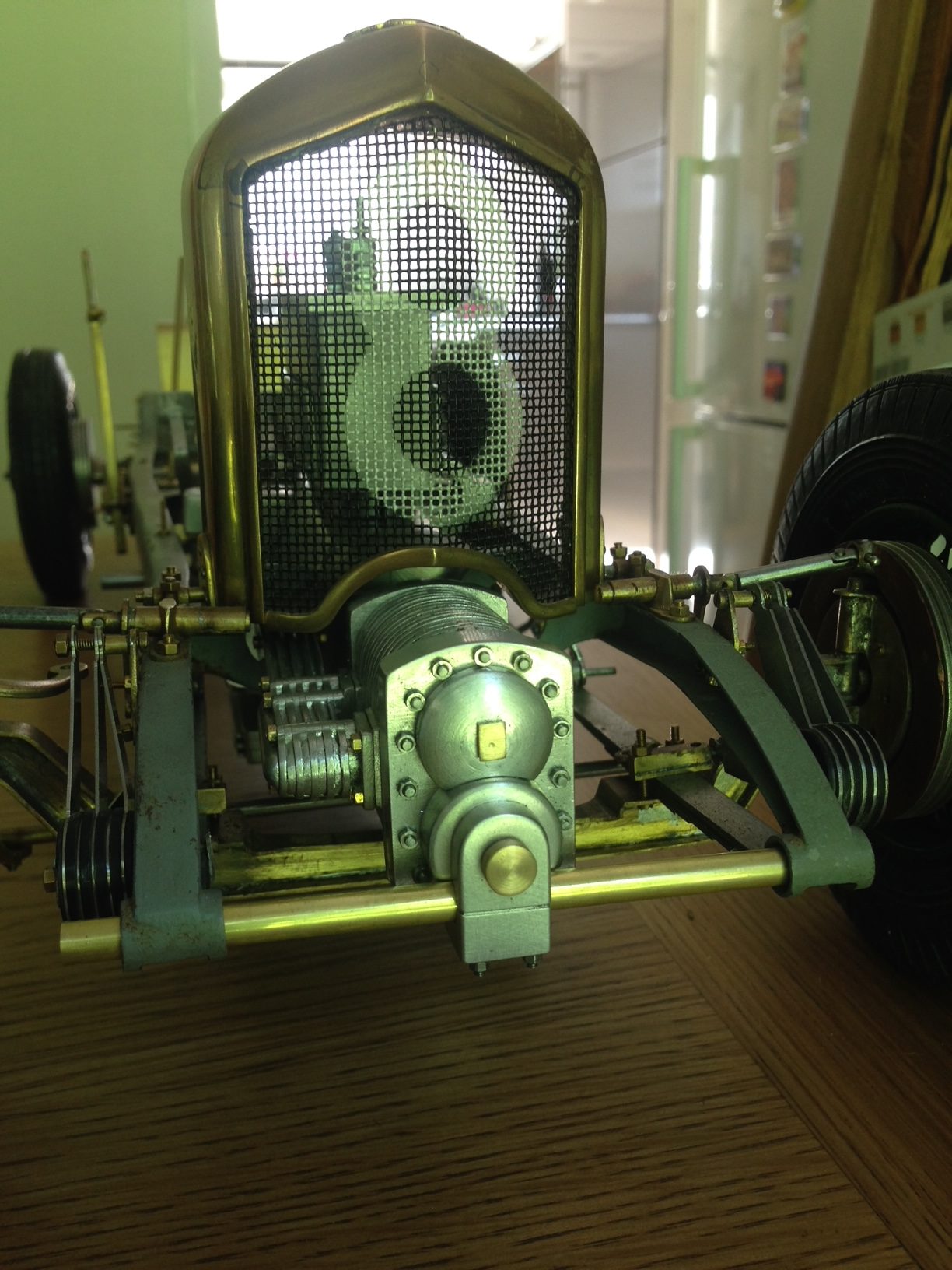

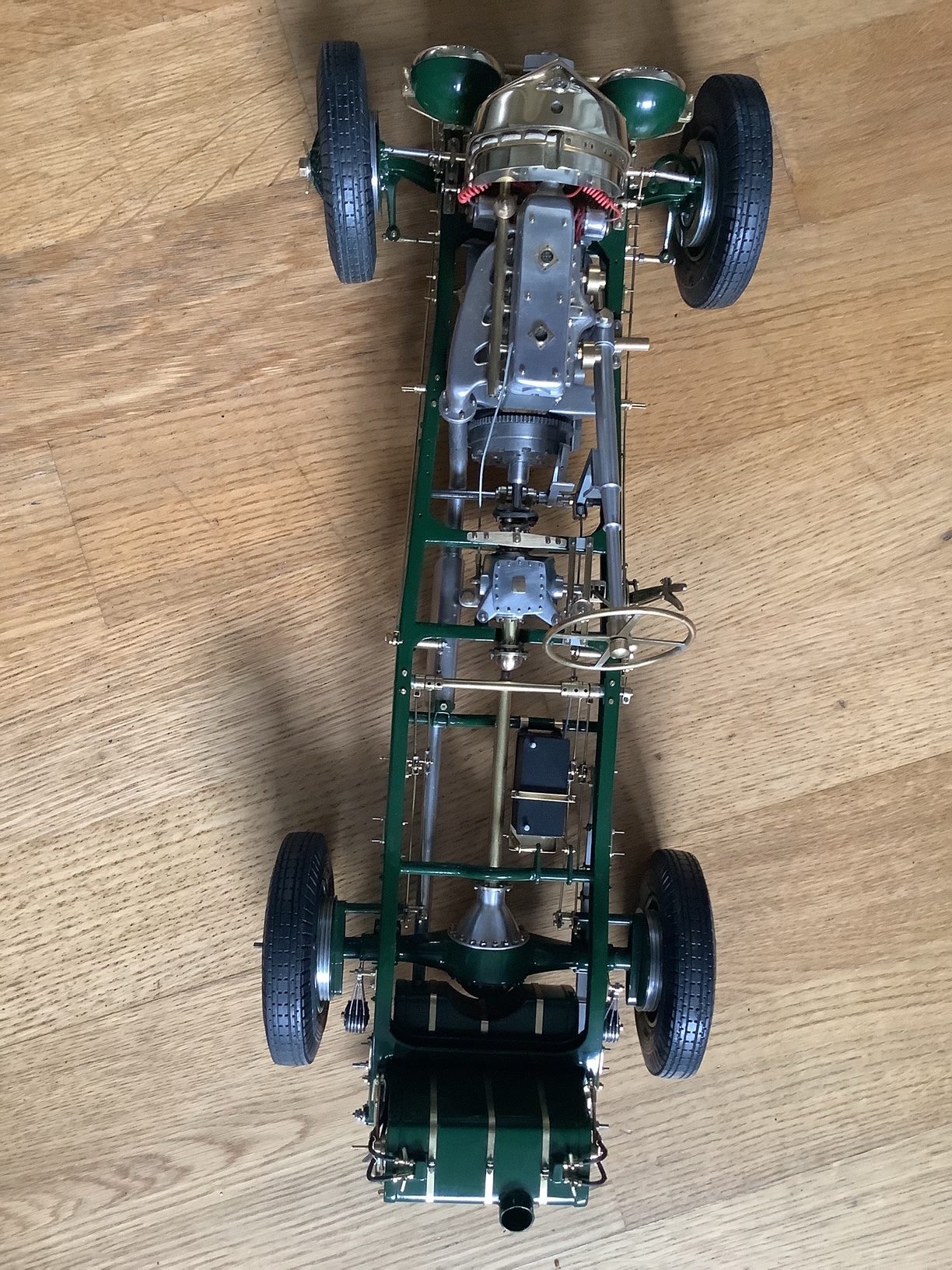

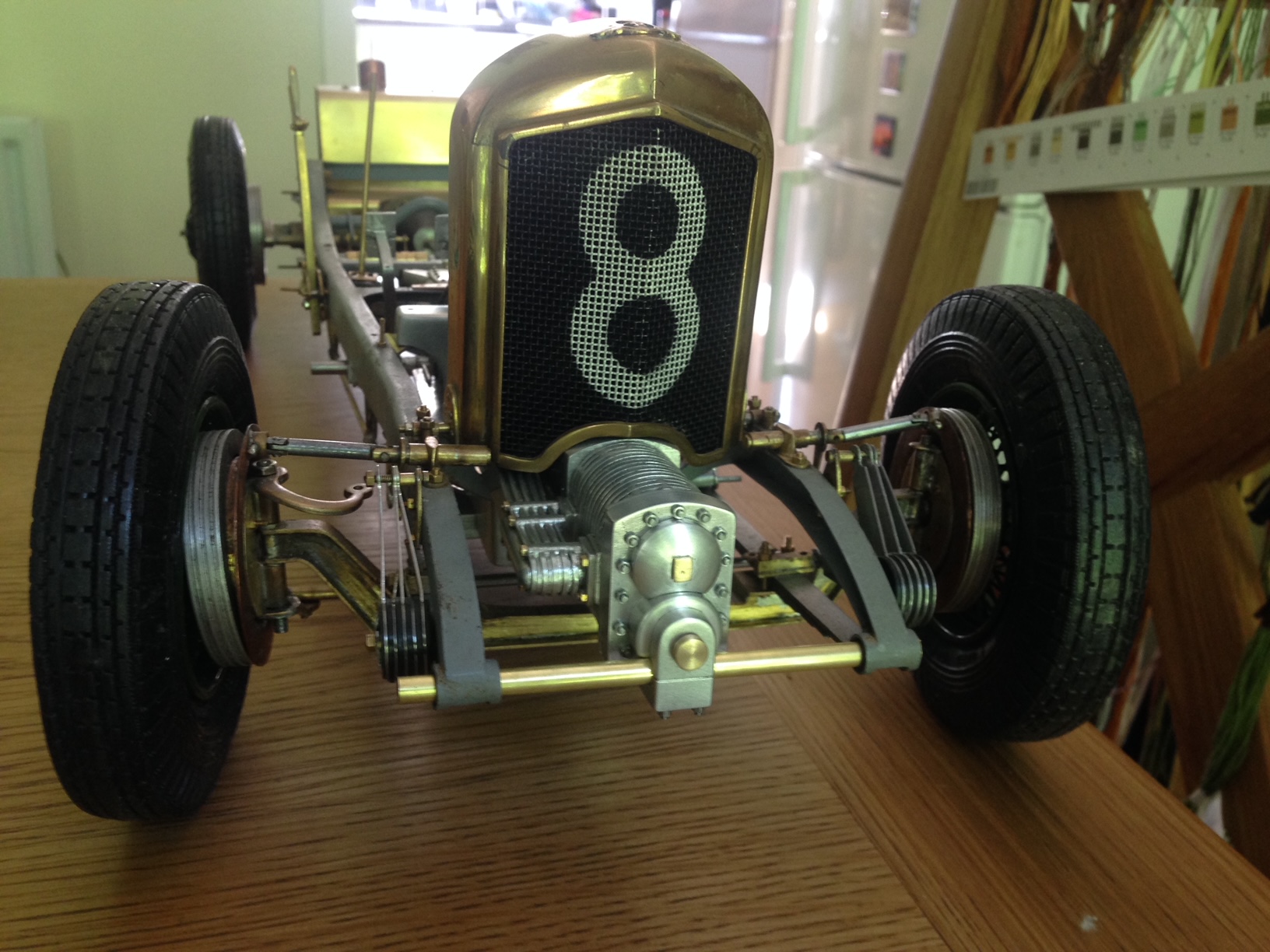

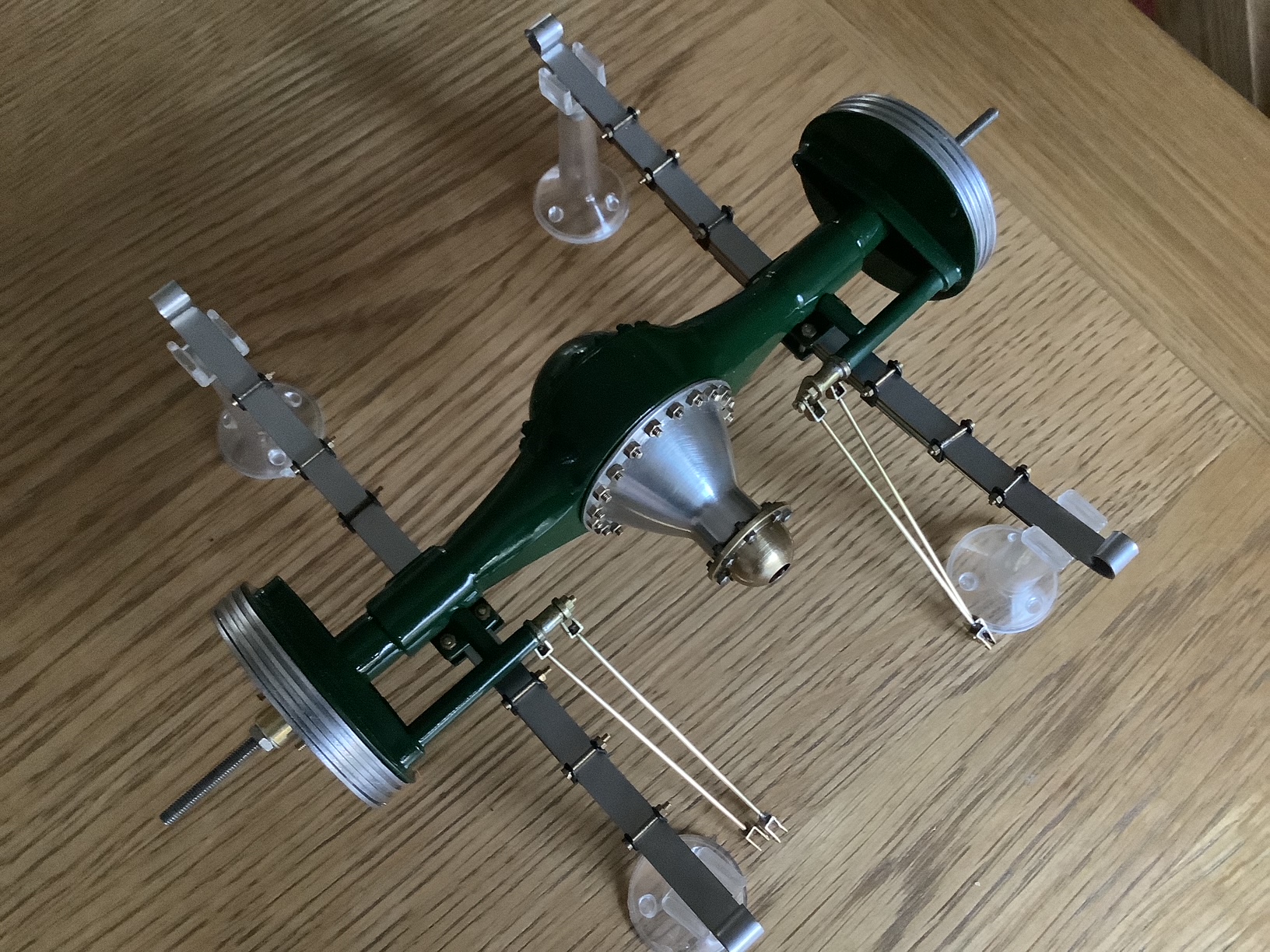

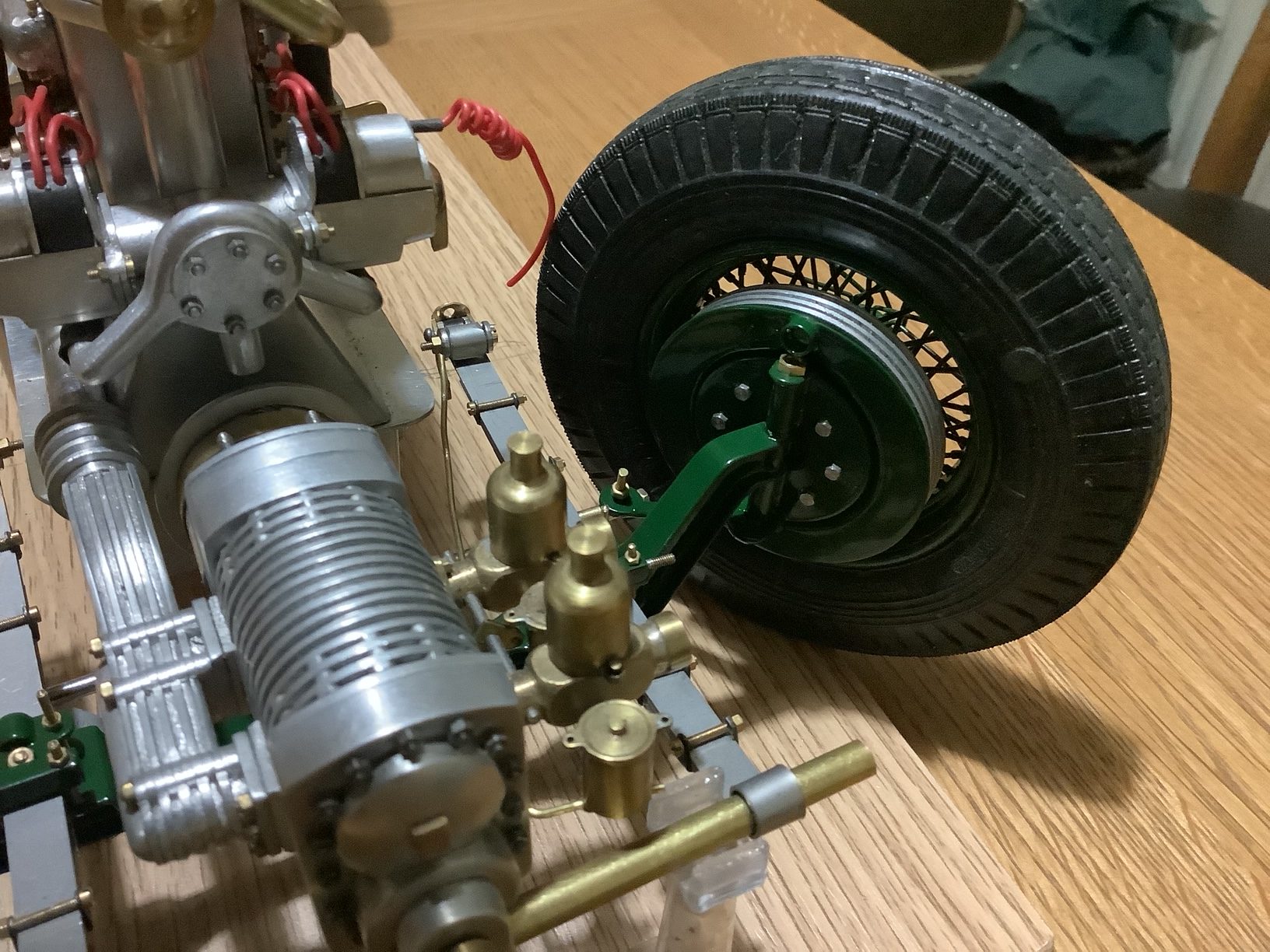

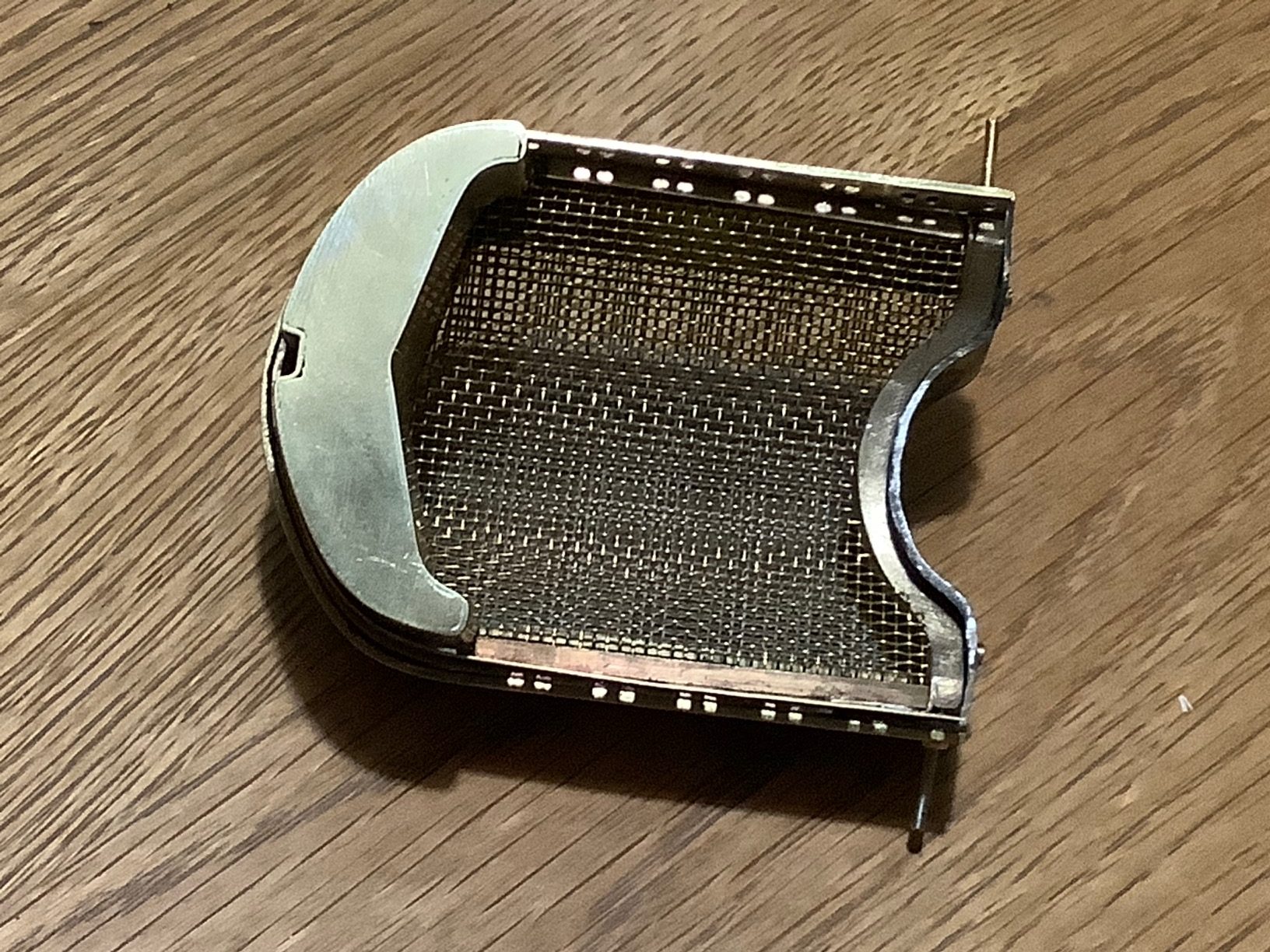

This is not a kit, I have made every part from scratch except the tyres, and they are Pocher Rolls Royce donated by Model Motorcars. I had no lathe or milling machine. The radiator was the first part I made, this is constructed from brass sheet and bar. A hardwood pattern was made first, I used this to make a cardboard template of the sides and top because the radiator tapers it couldn't be just a flat strip, more of a very flat "N" shape but with added flaps that would form the front sides. The cardboard template was transferred onto brass sheet, the front faces bent in and then curved into horseshoe shape, a square block was then silver soldered into the top and filed to give the correct profile, the flanges for the grille then added. The wheel rims were first turned in plaster of Paris molded in rubber, and cast in polyester resin, for the hubs a similar method, but the mold was made to incorporate pre-drilled brass strips bent and soldered into rings which would incorporate the spokes. The spokes themselves are long dressmakers pins, with the heads inside the hubs. Holes for the spokes in the rims were drilled from the inside with help from a pre-drilled template bent into a ring and placed inside the rim, short pieces of plastic wire insulation were slid onto each spoke after being passed through the holes in the hub, then down the spoke until they entered the hole in the rim, all this being done on a gig to keep everything central.

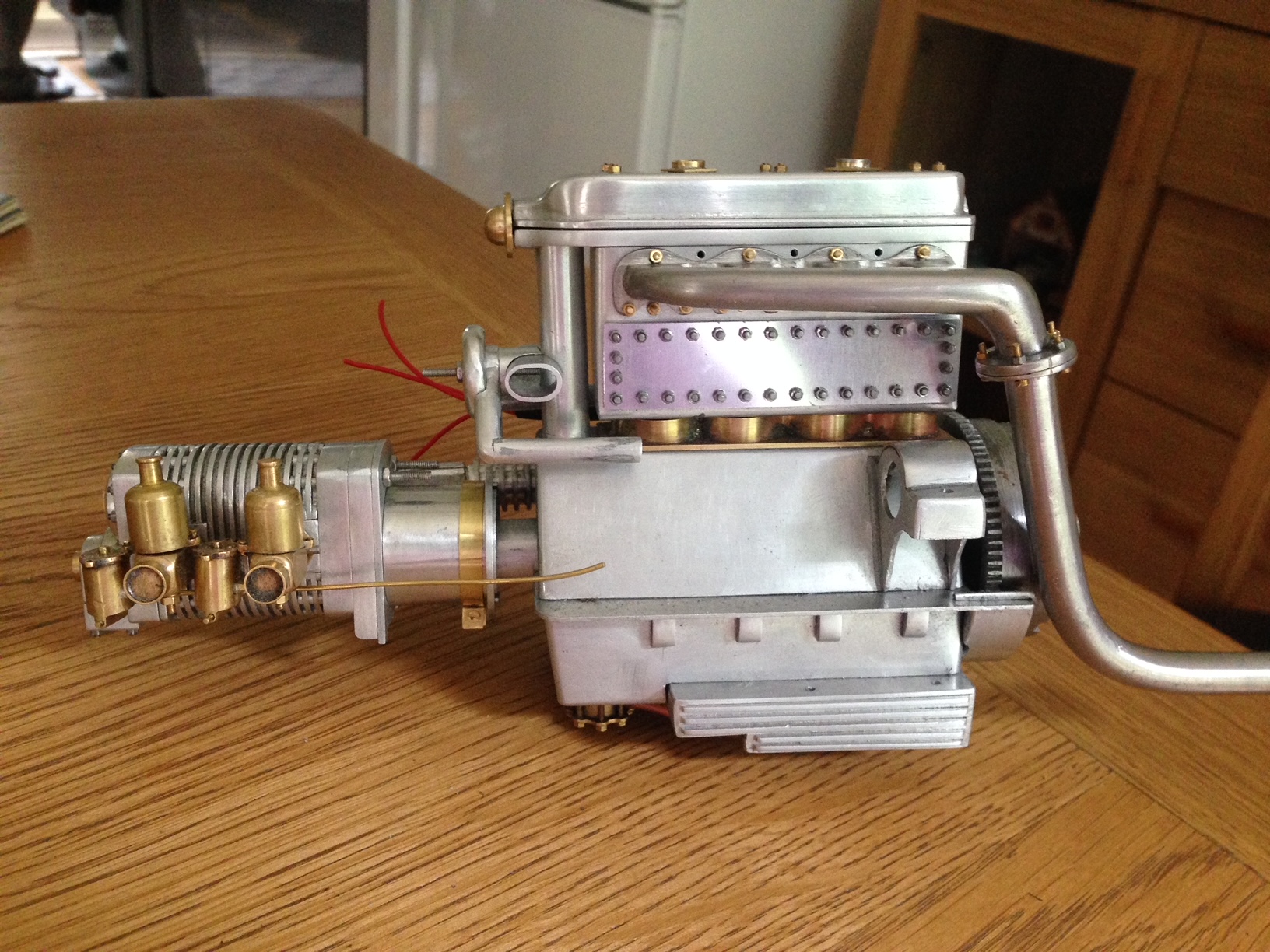

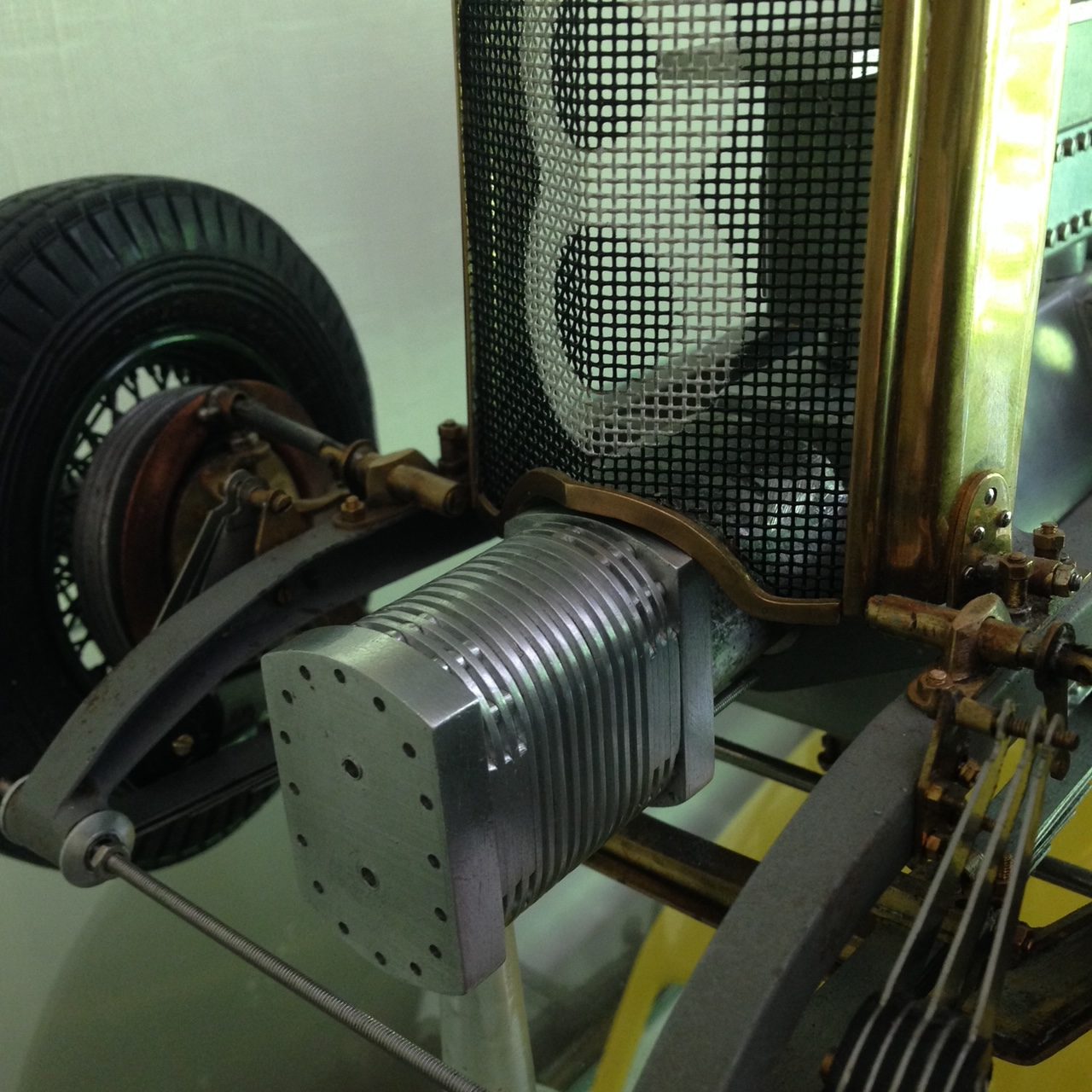

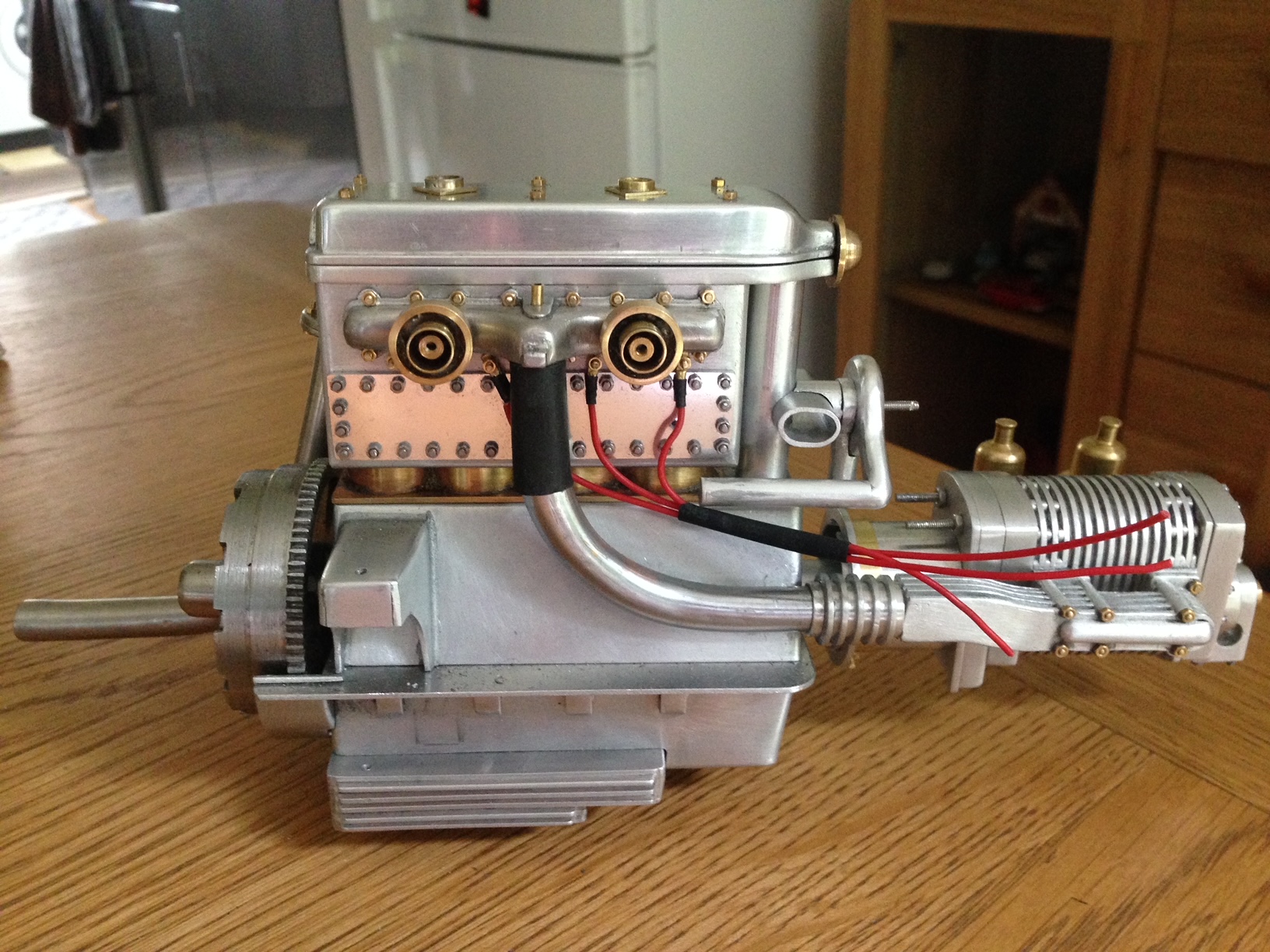

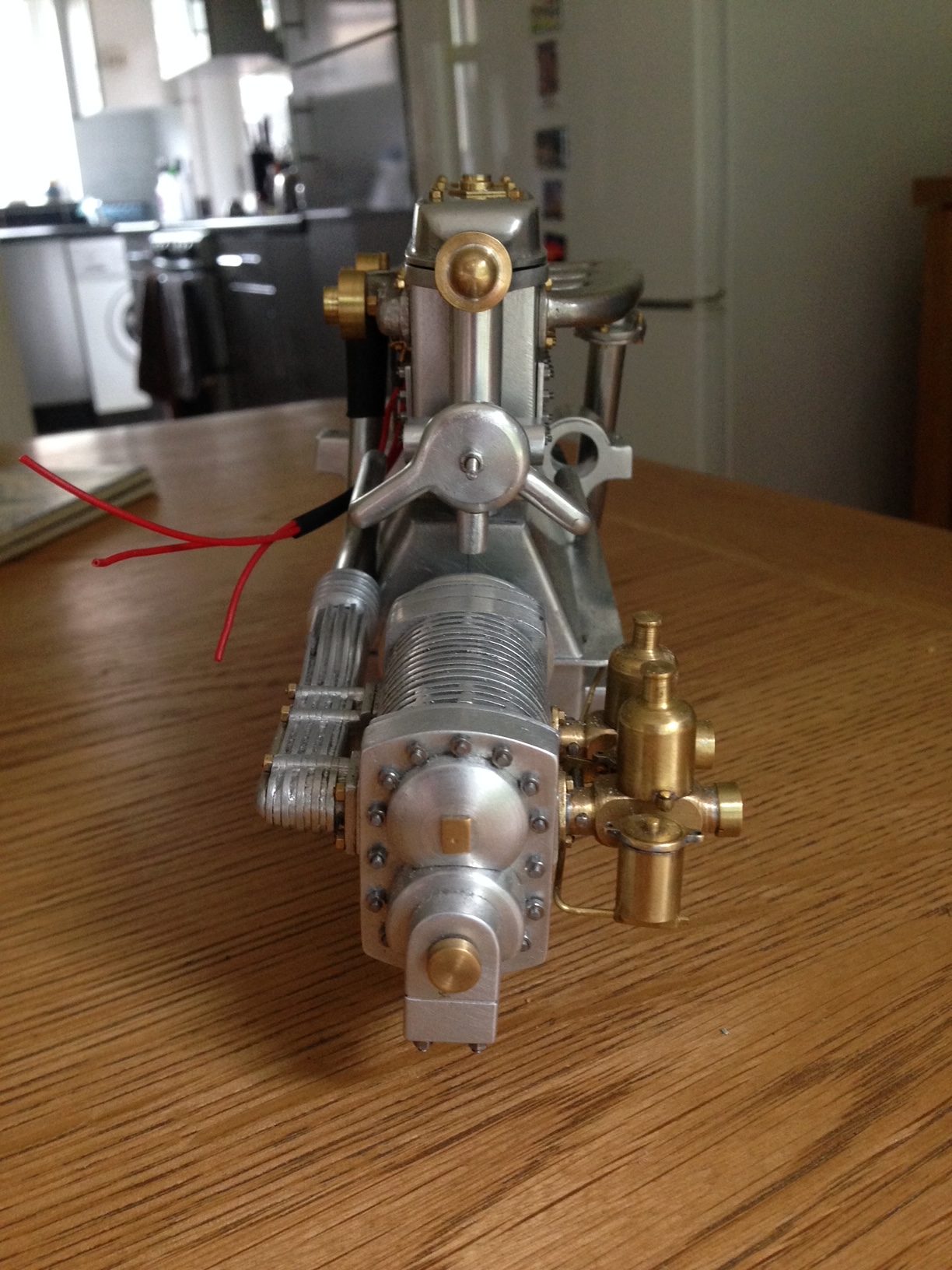

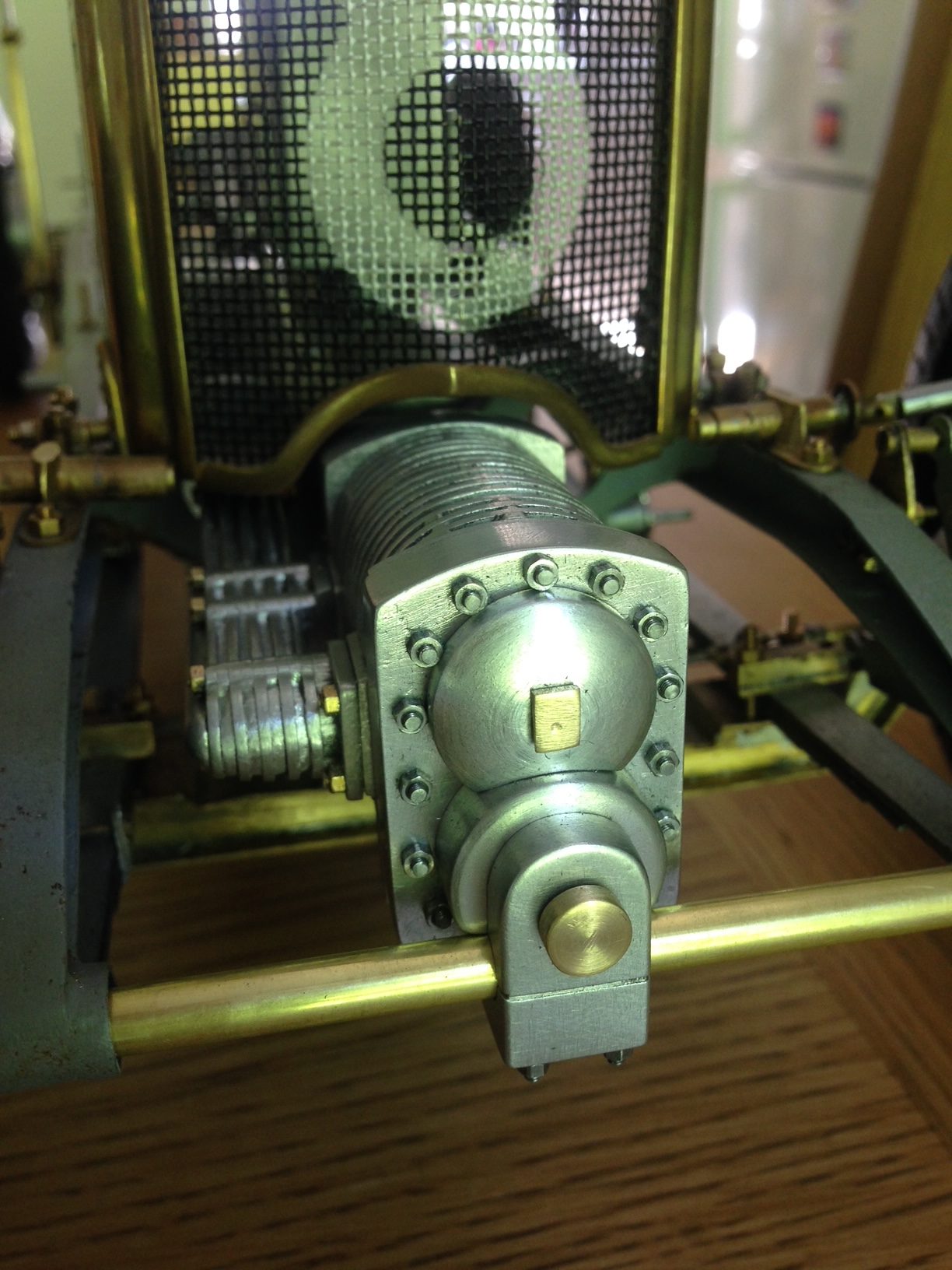

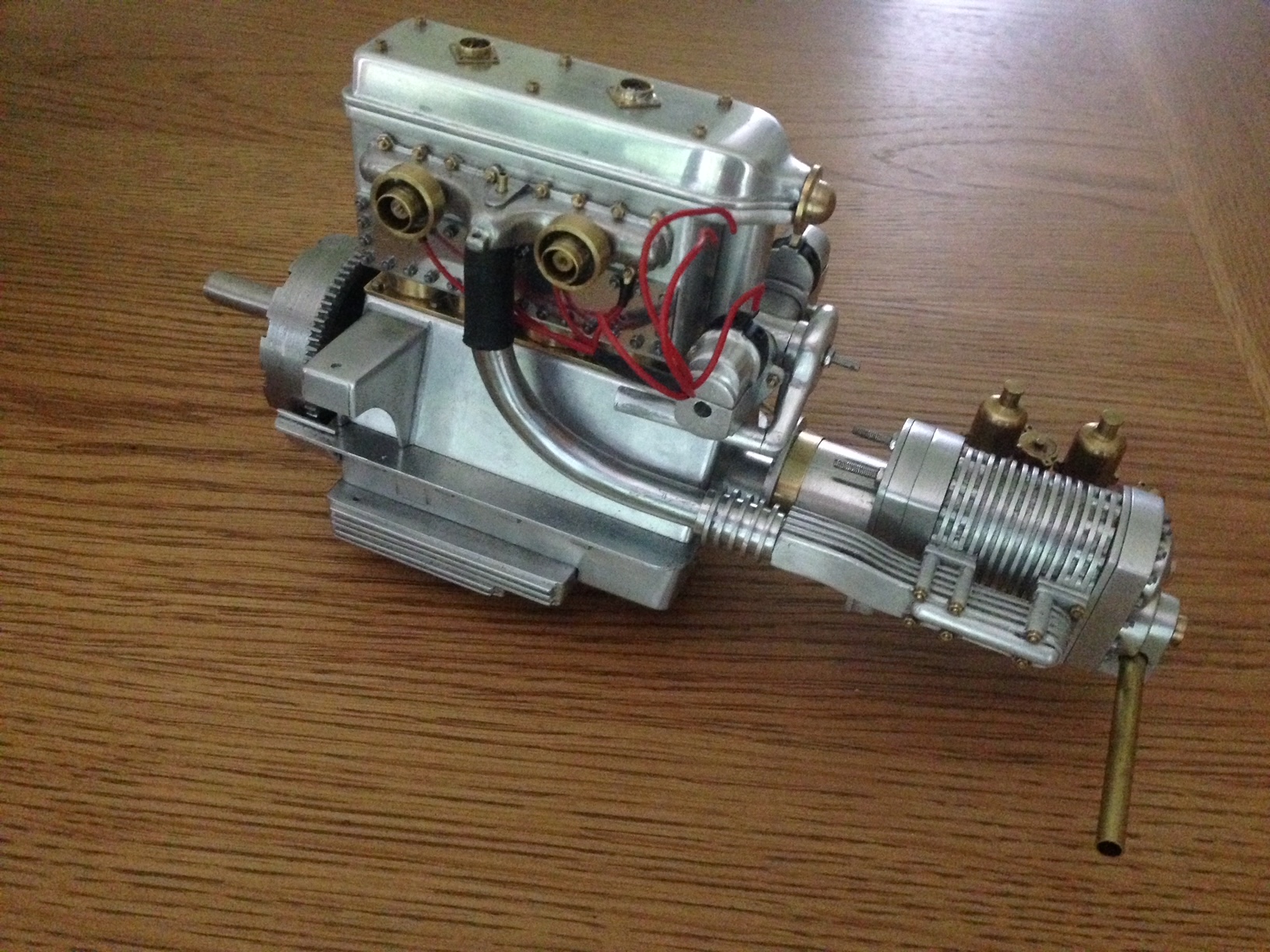

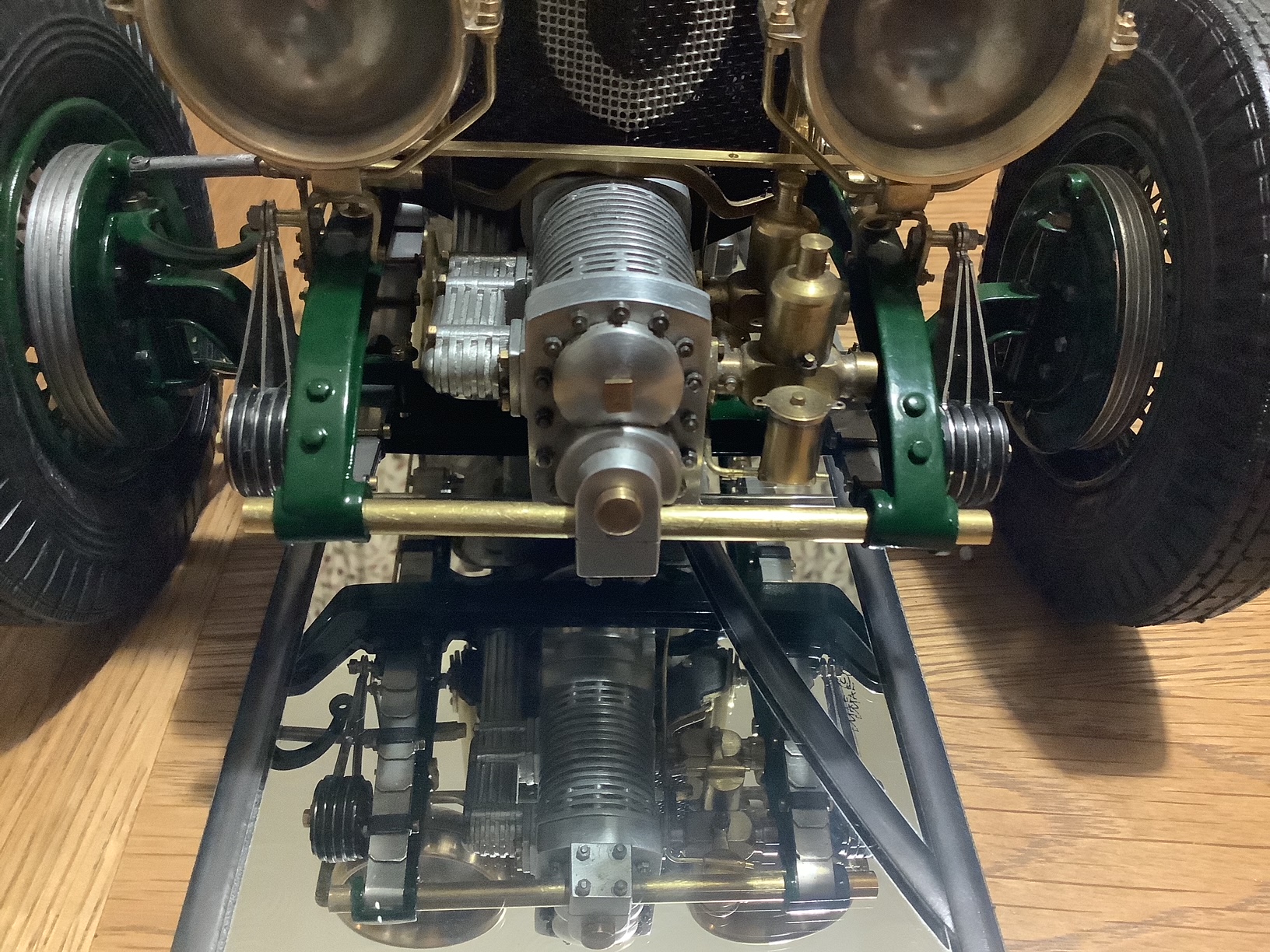

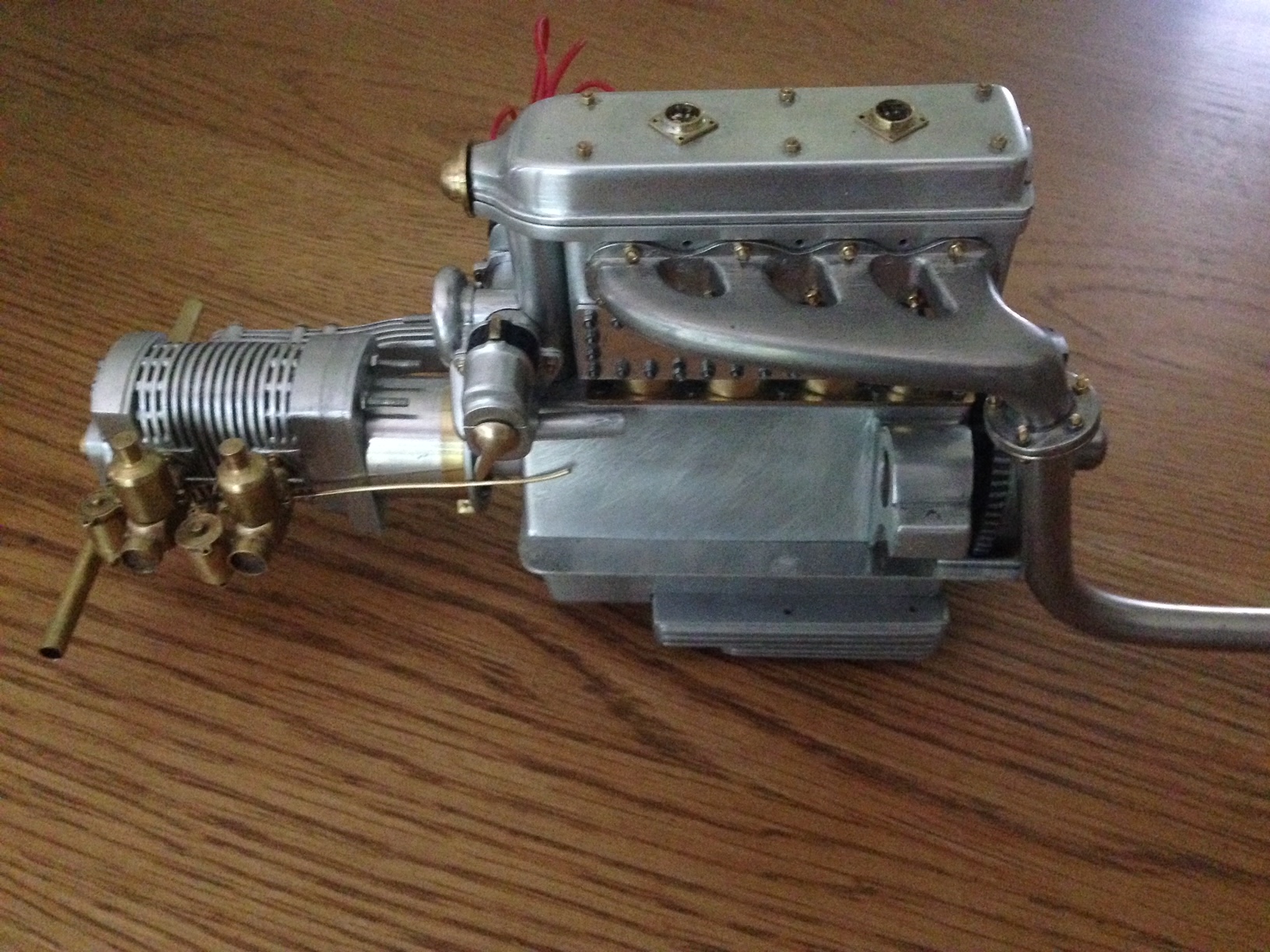

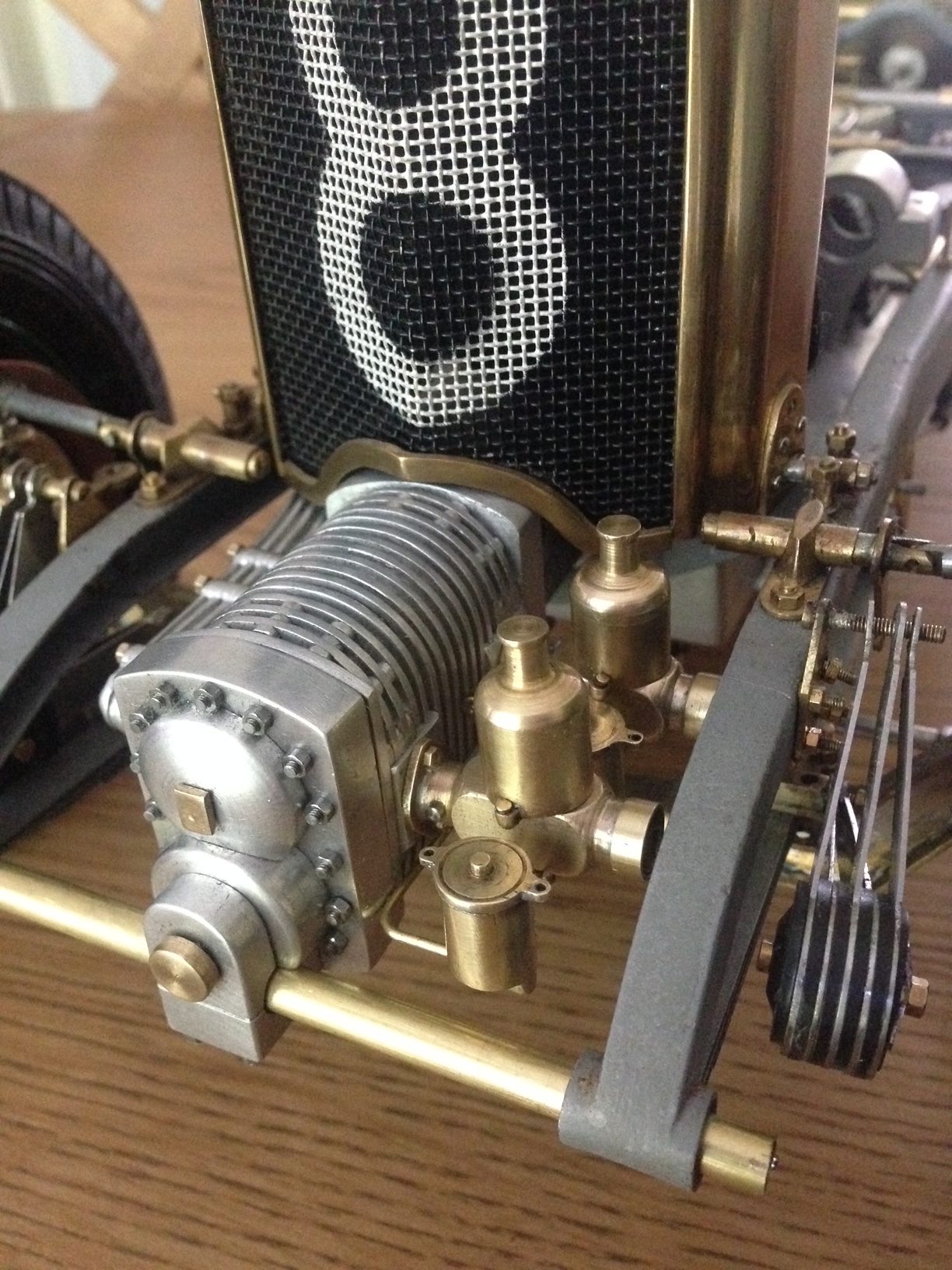

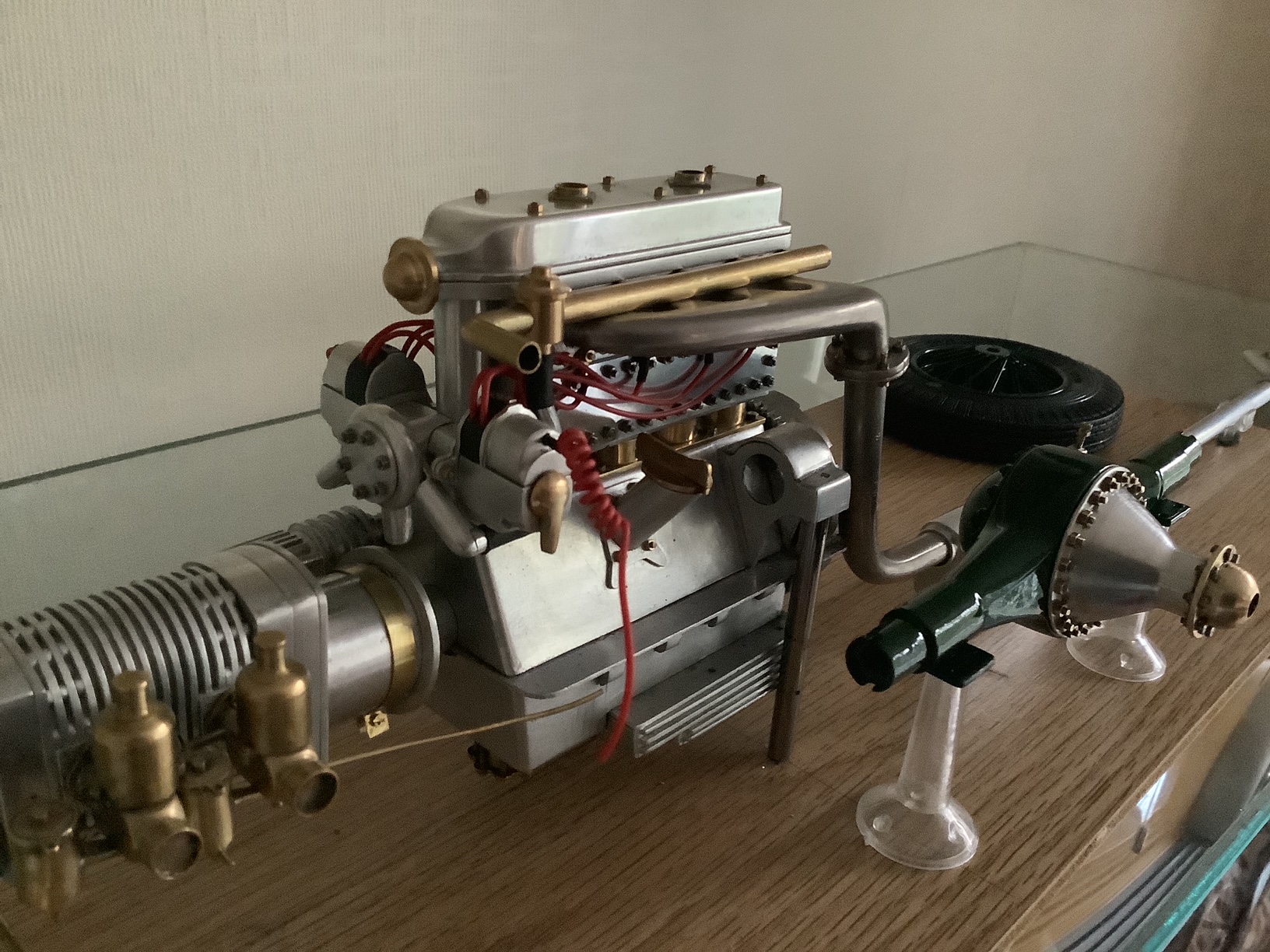

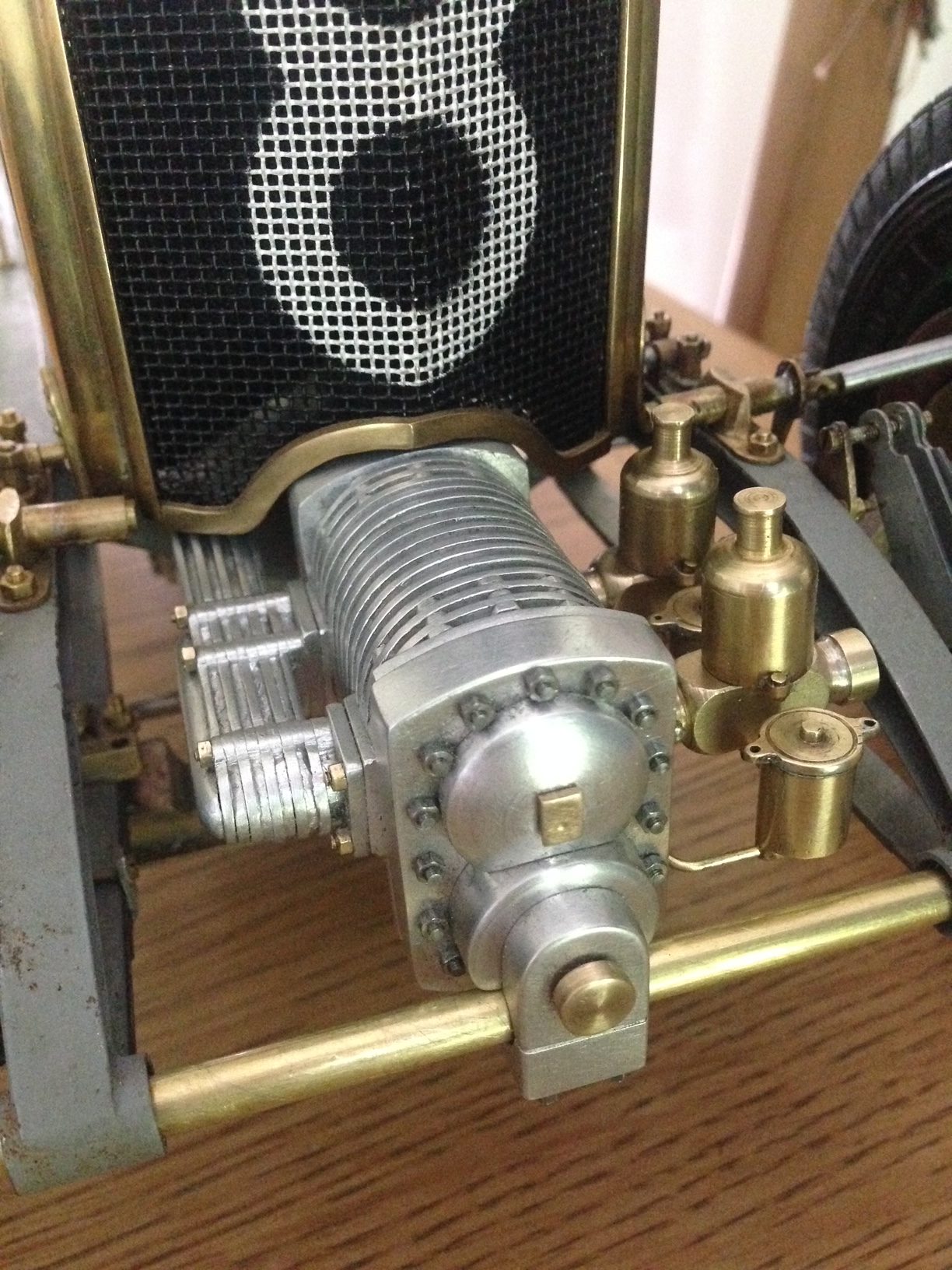

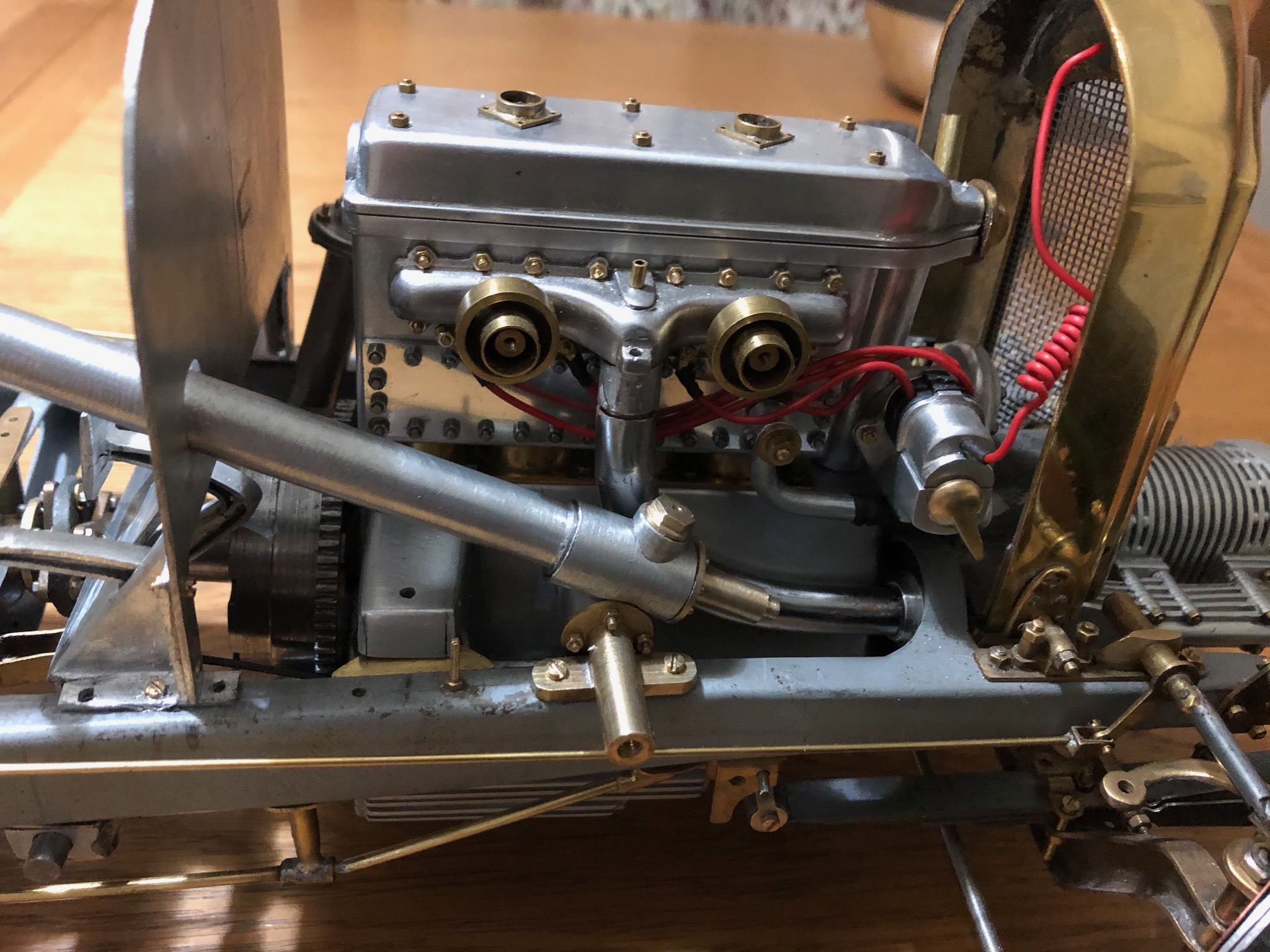

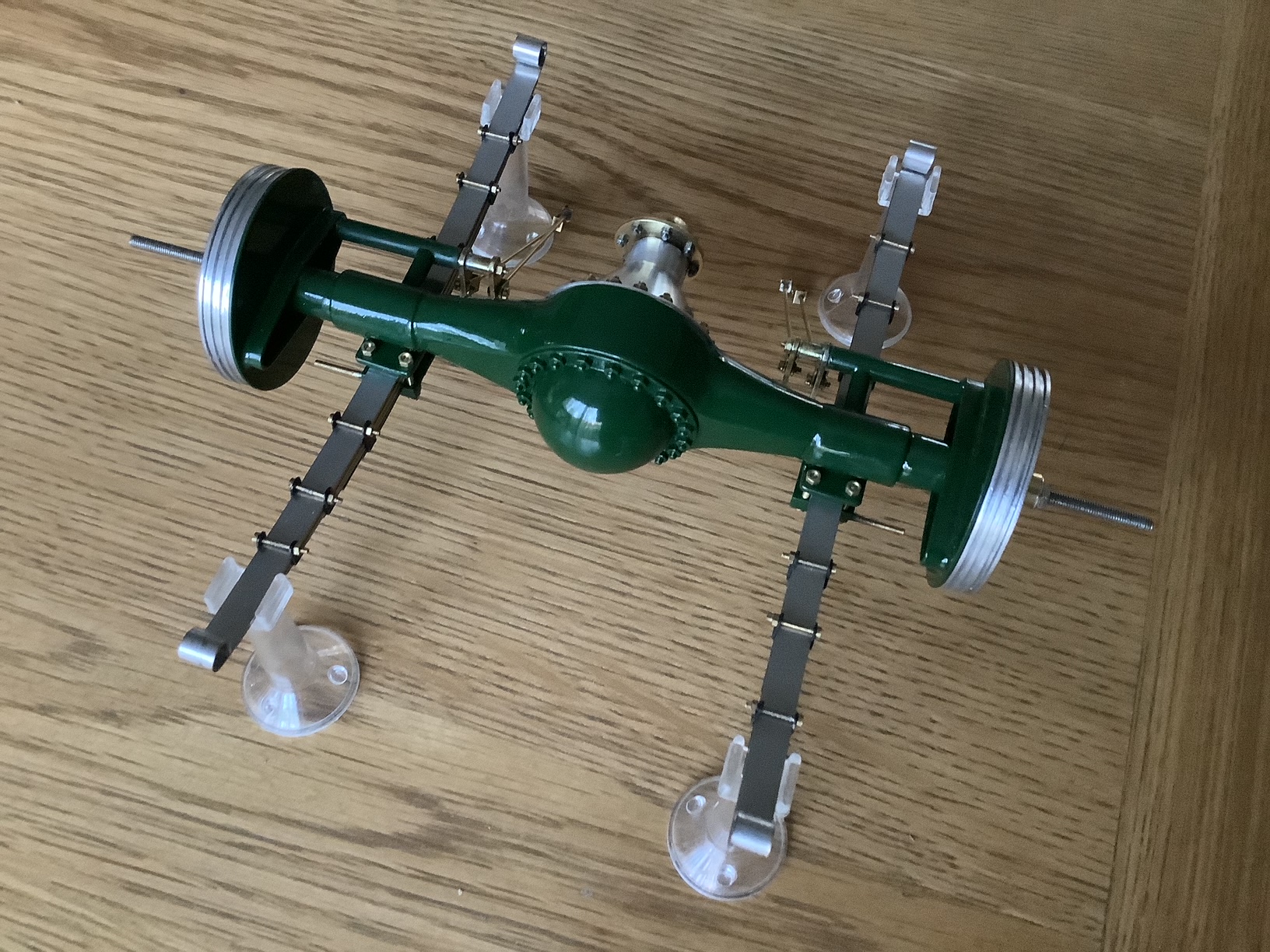

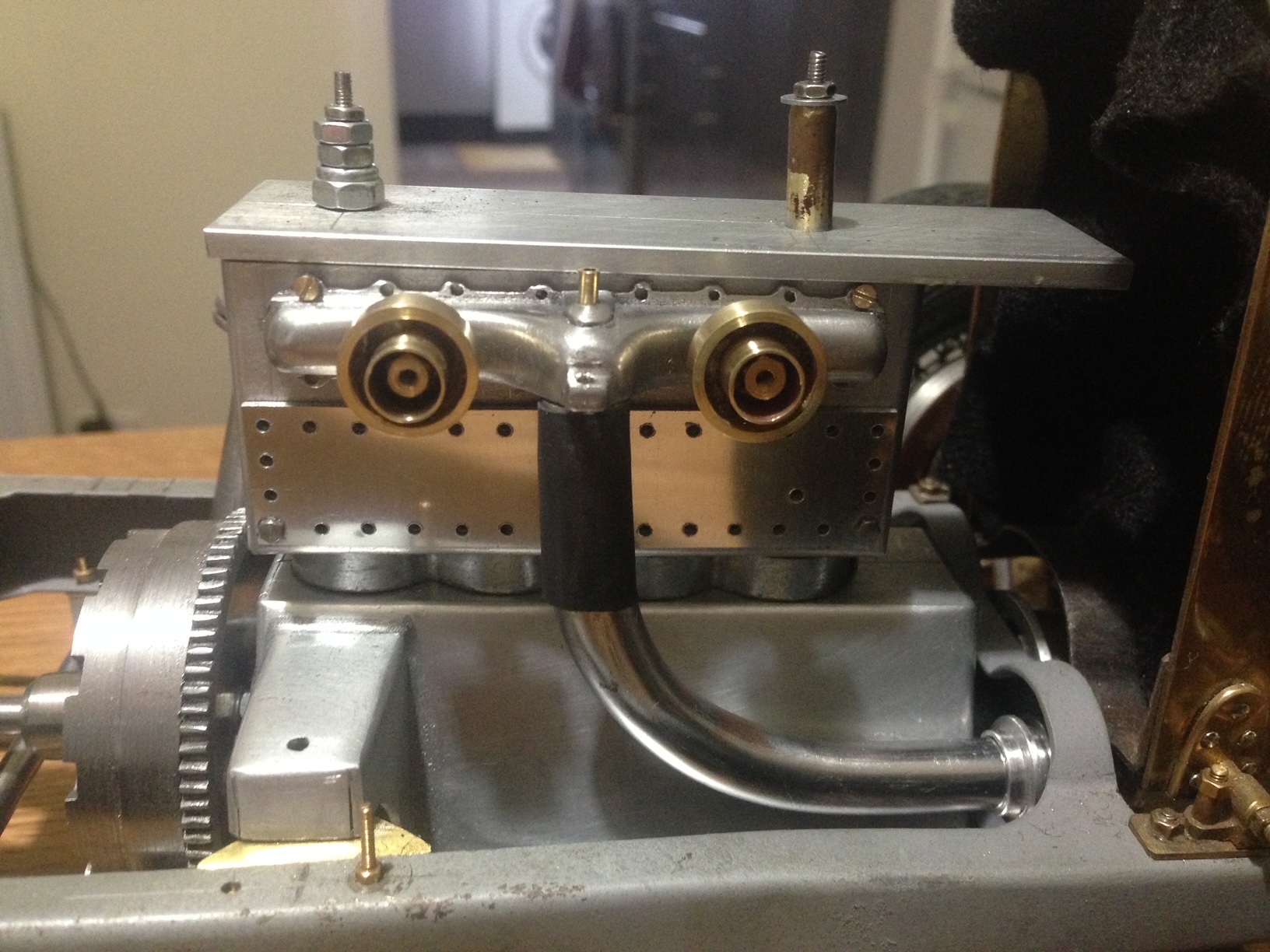

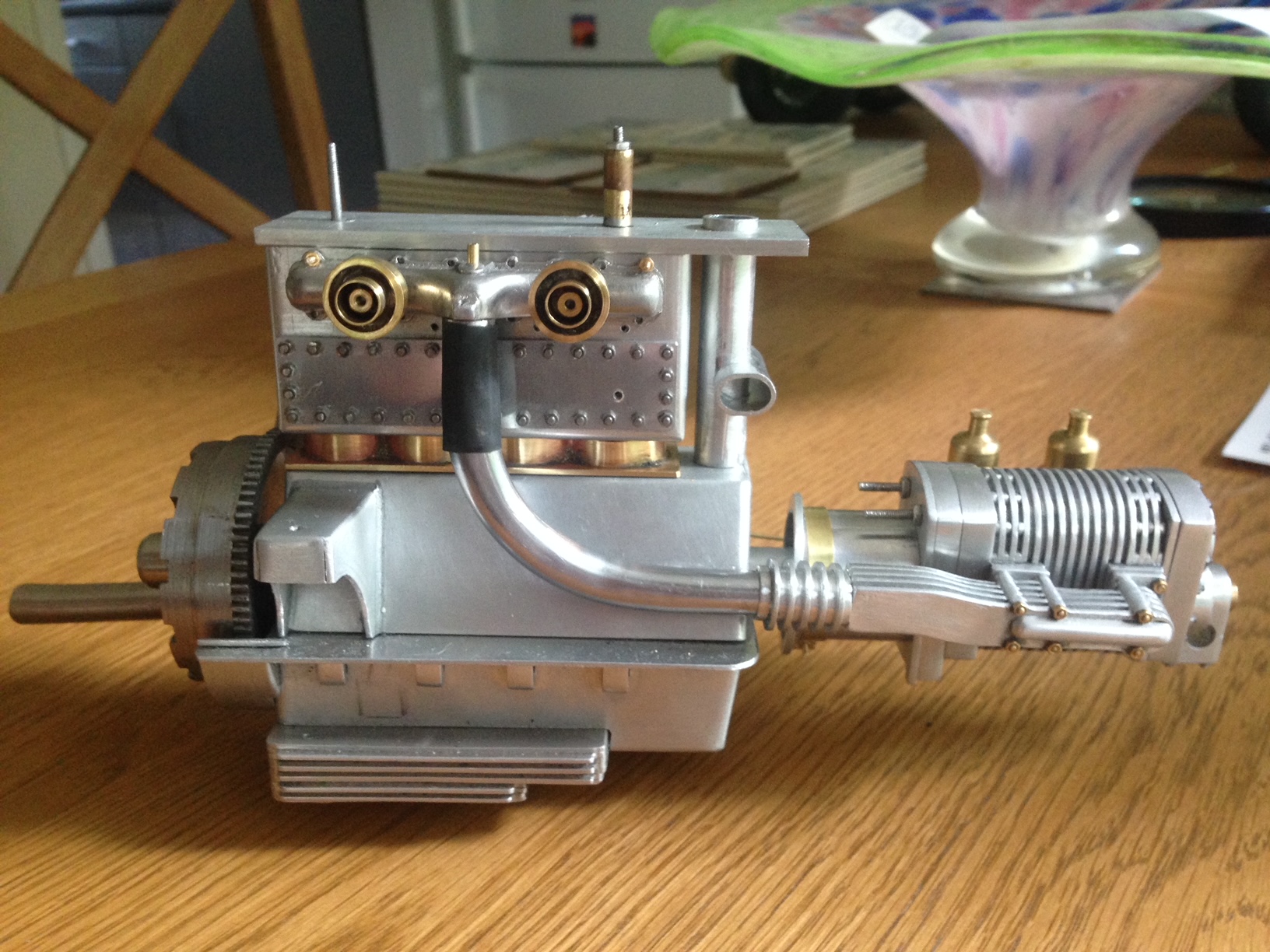

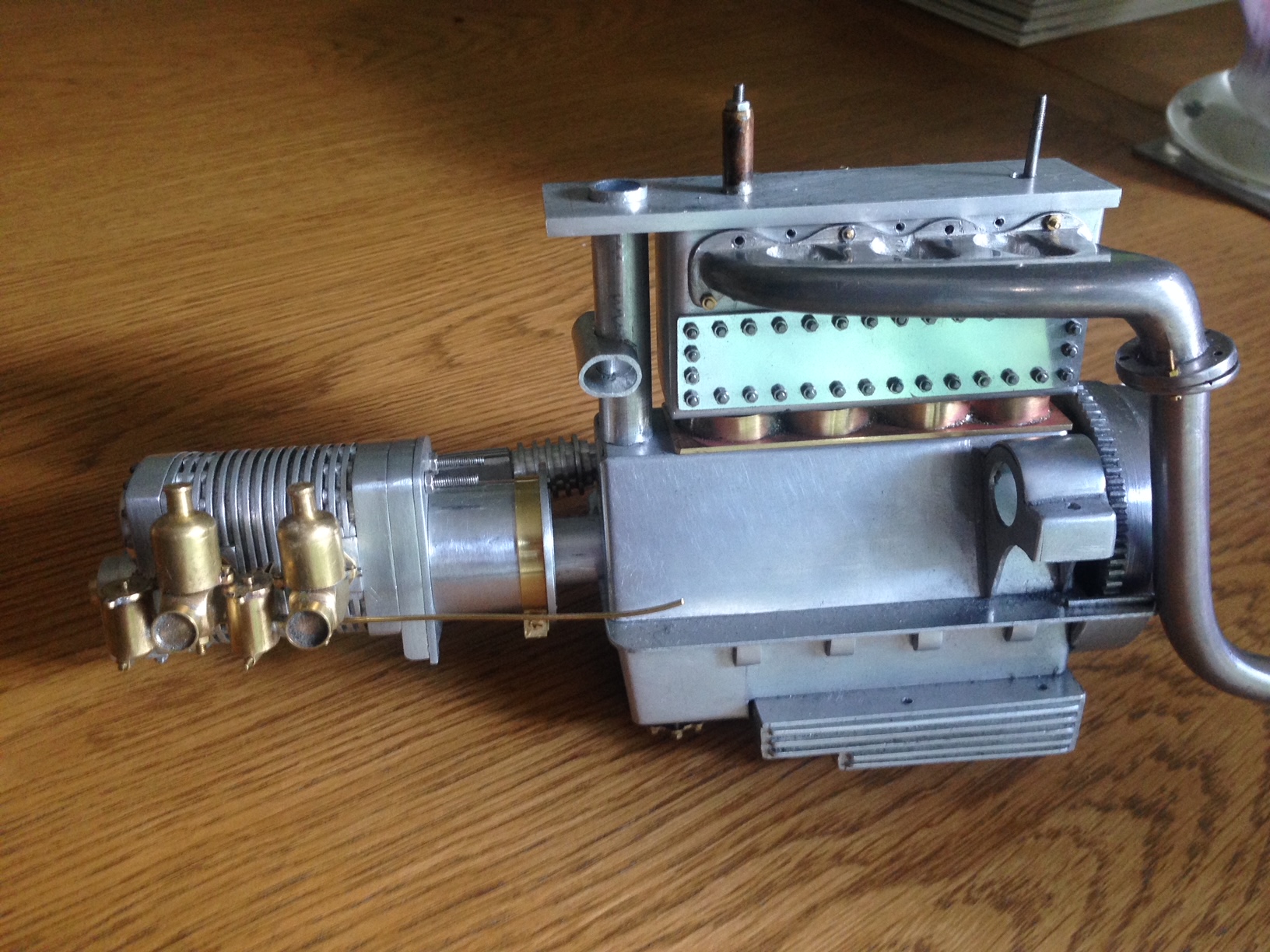

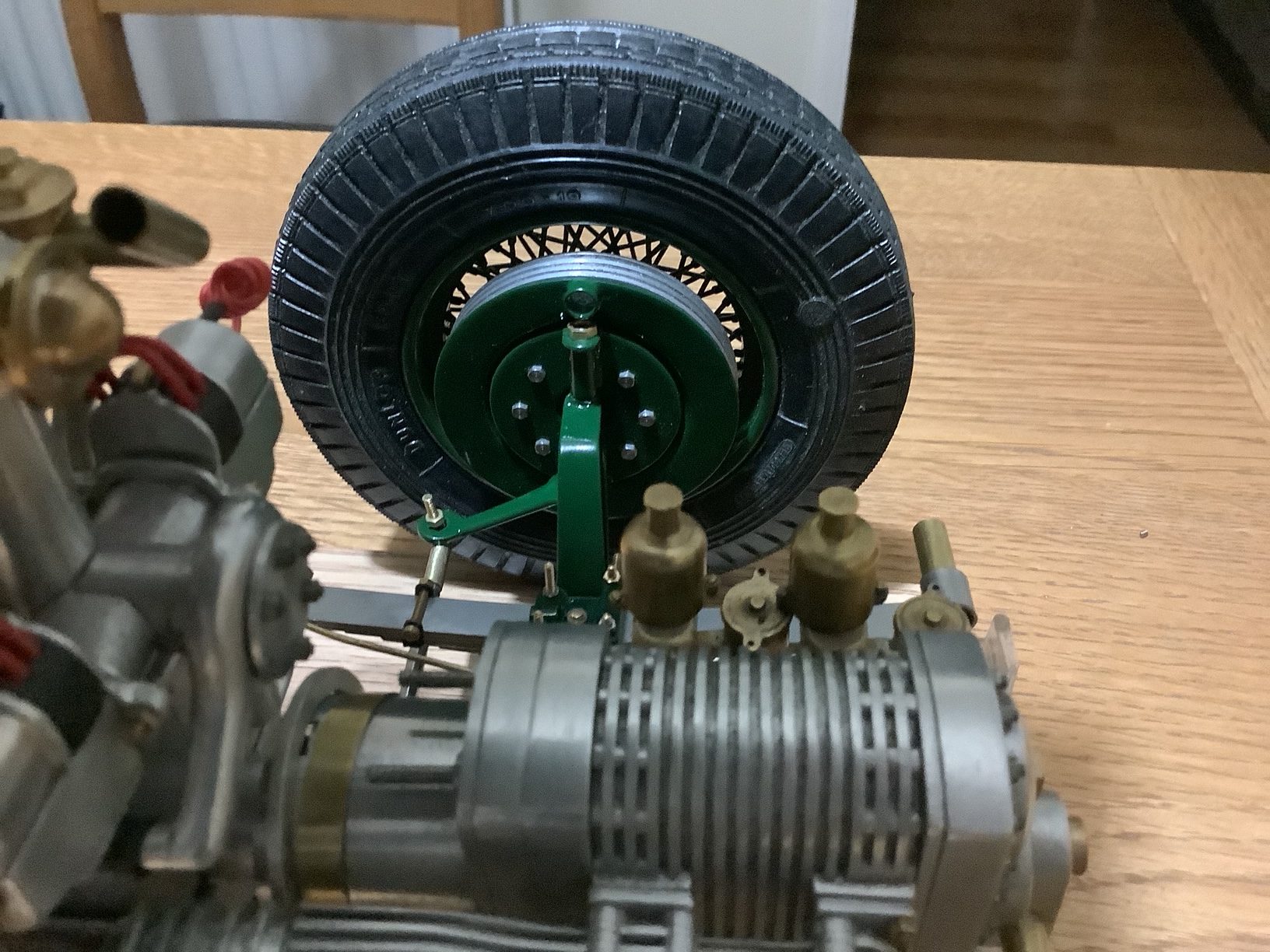

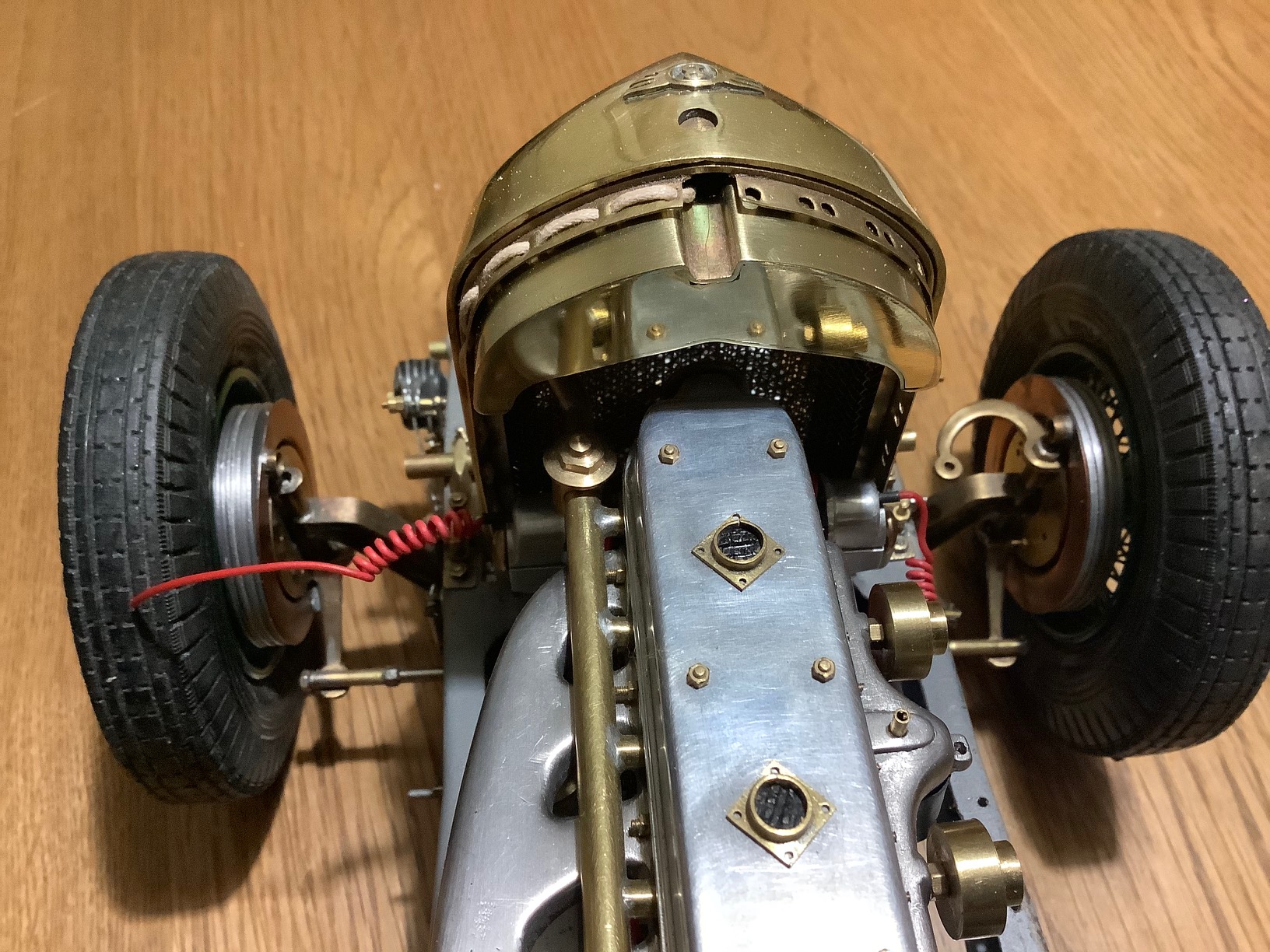

The supercharger is made of layers of aluminum sheet of varying thicknesses so as to form the fins. These layers are held together by four M3 nuts and bolts, these had to be very carefully placed so as not to show from the front, but also not get in the way of the tube, which was to mount the supercharger to the engine.

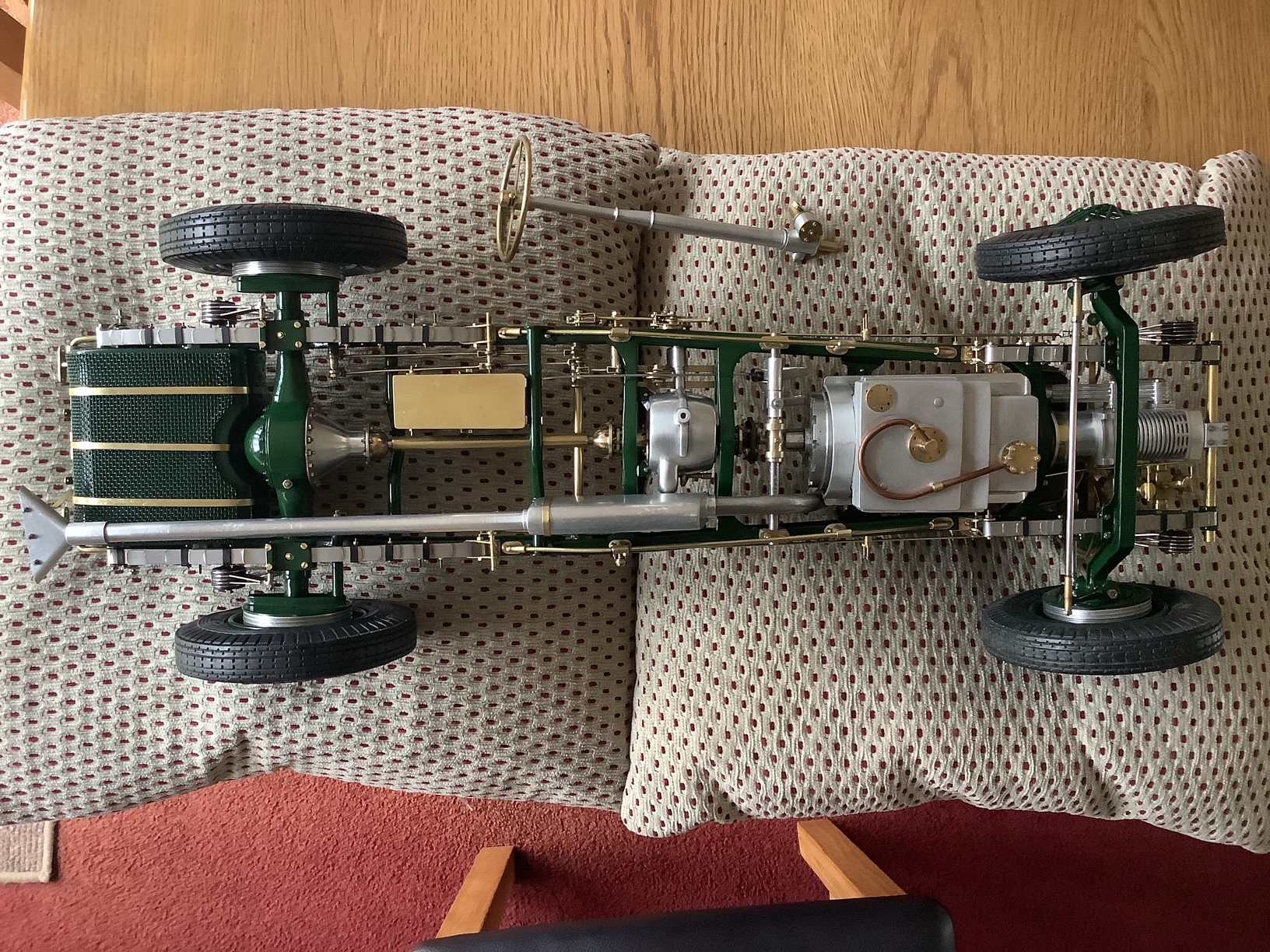

Brake drums similar to supercharge, basically alternatively sized washers.

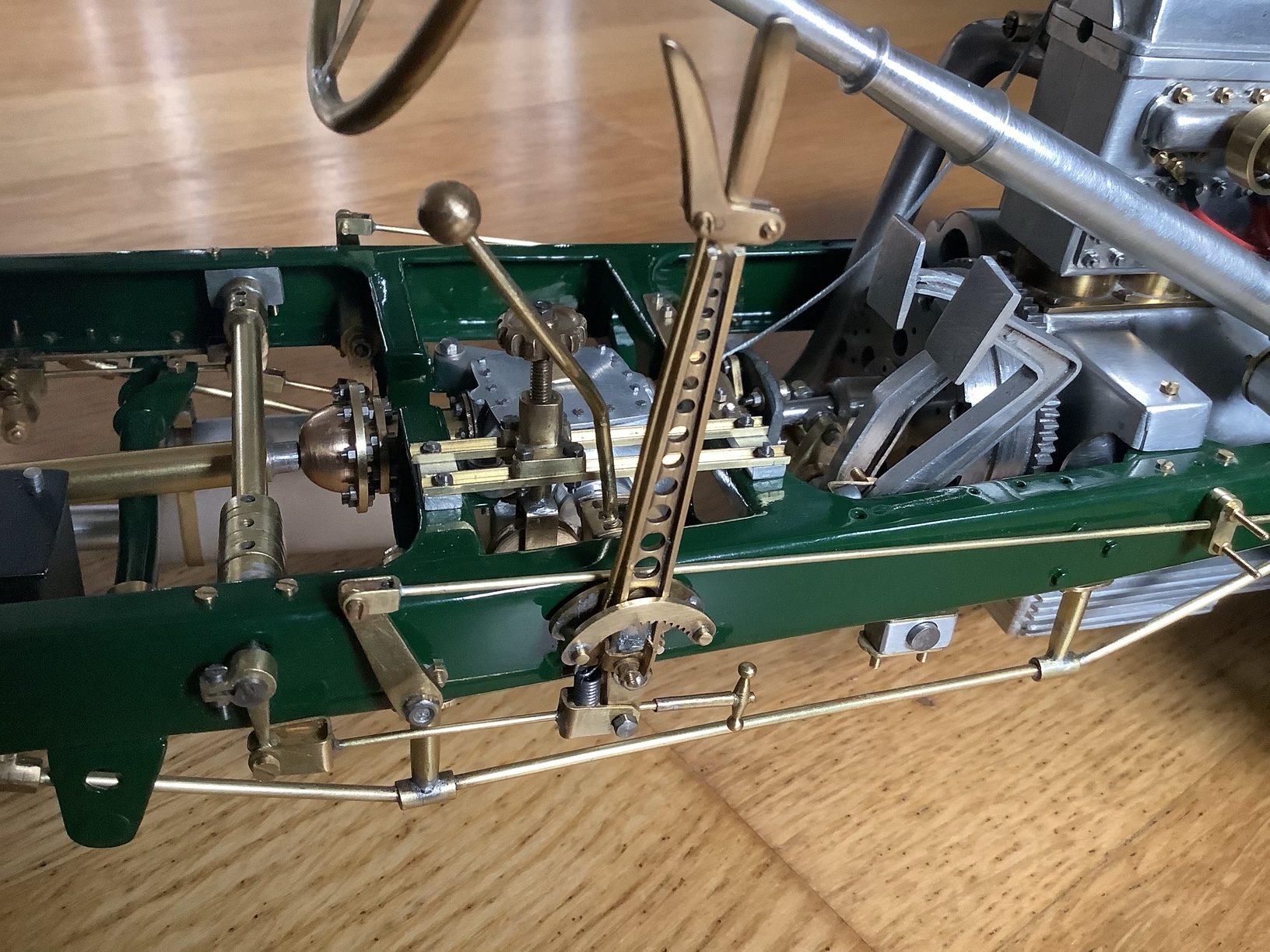

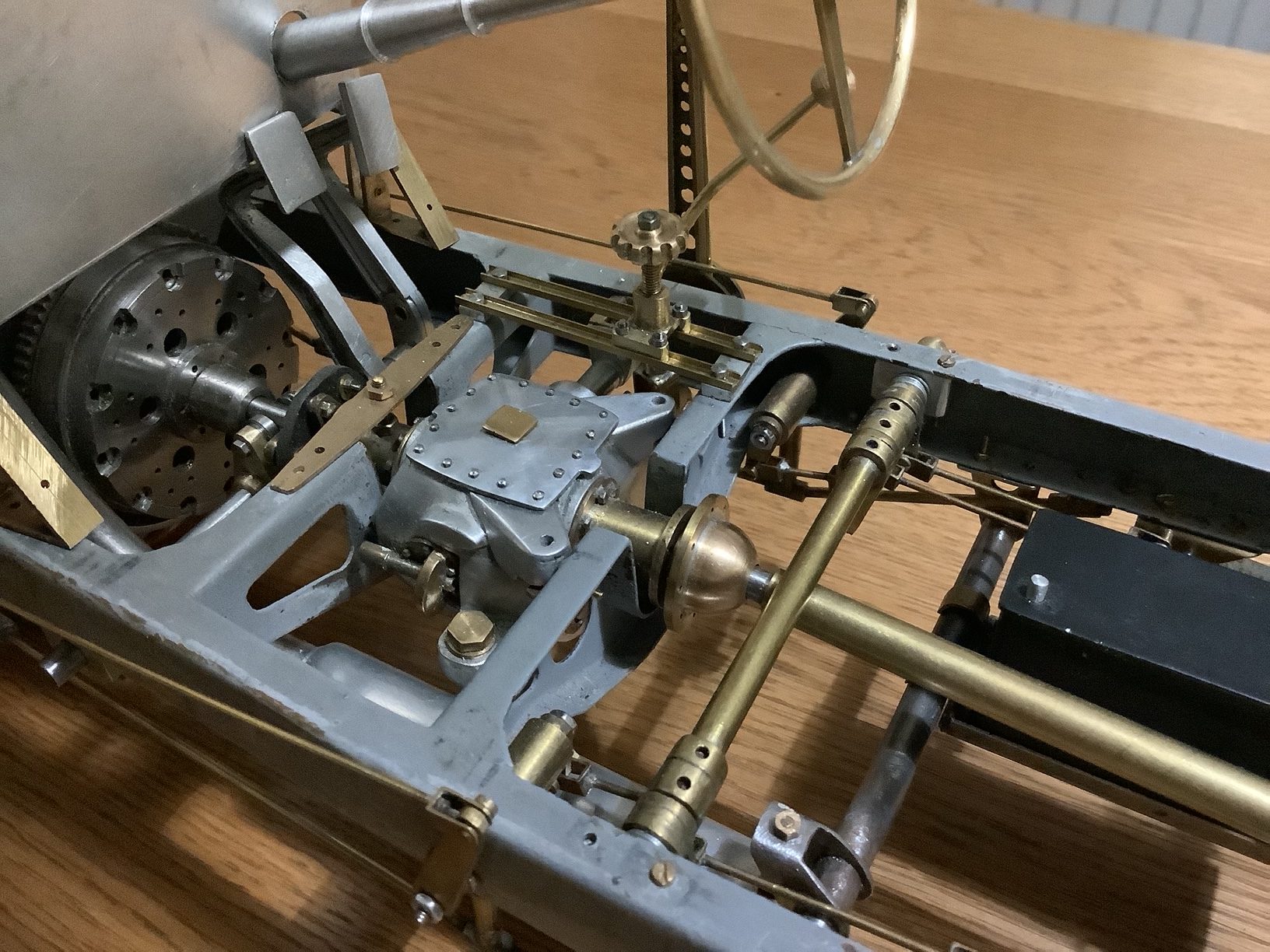

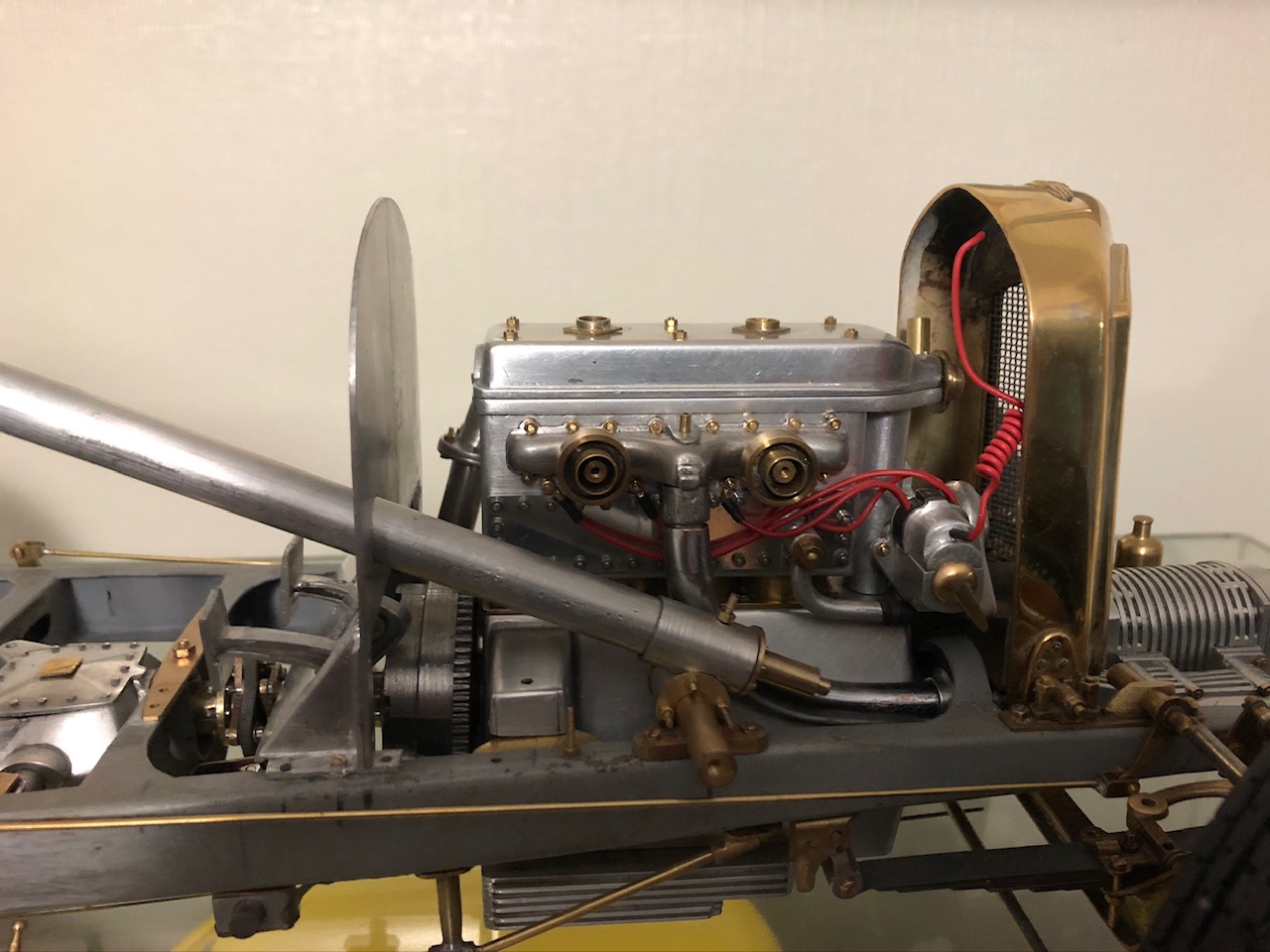

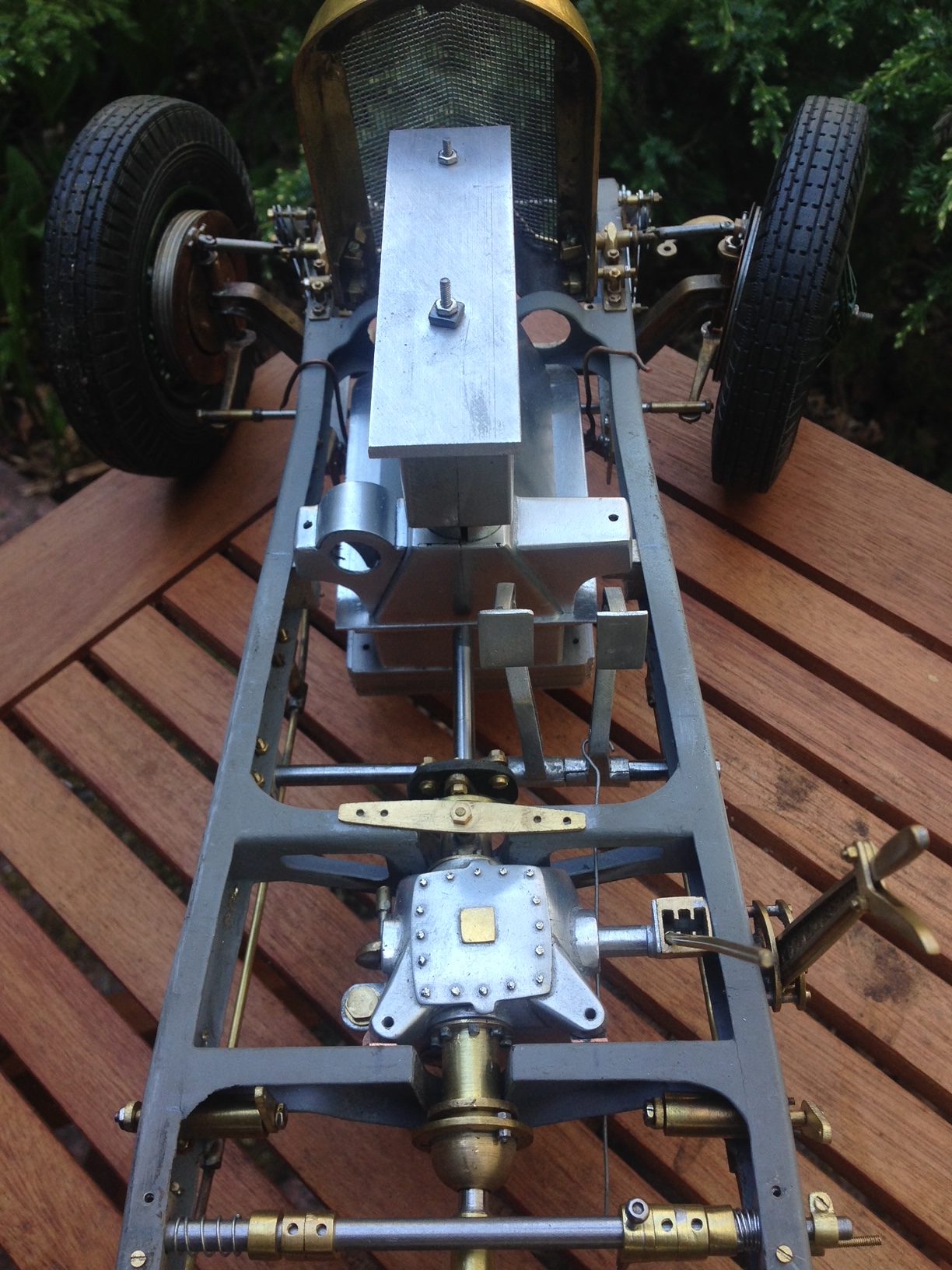

Gearbox again made up of layers, but then filled and smoothed into shape.

Engine block is made of folded aluminum sheet, with the mountings made separate then keyed into place. The finned sump built up in layers, and the rocker cover carved and filed from solid aluminum.

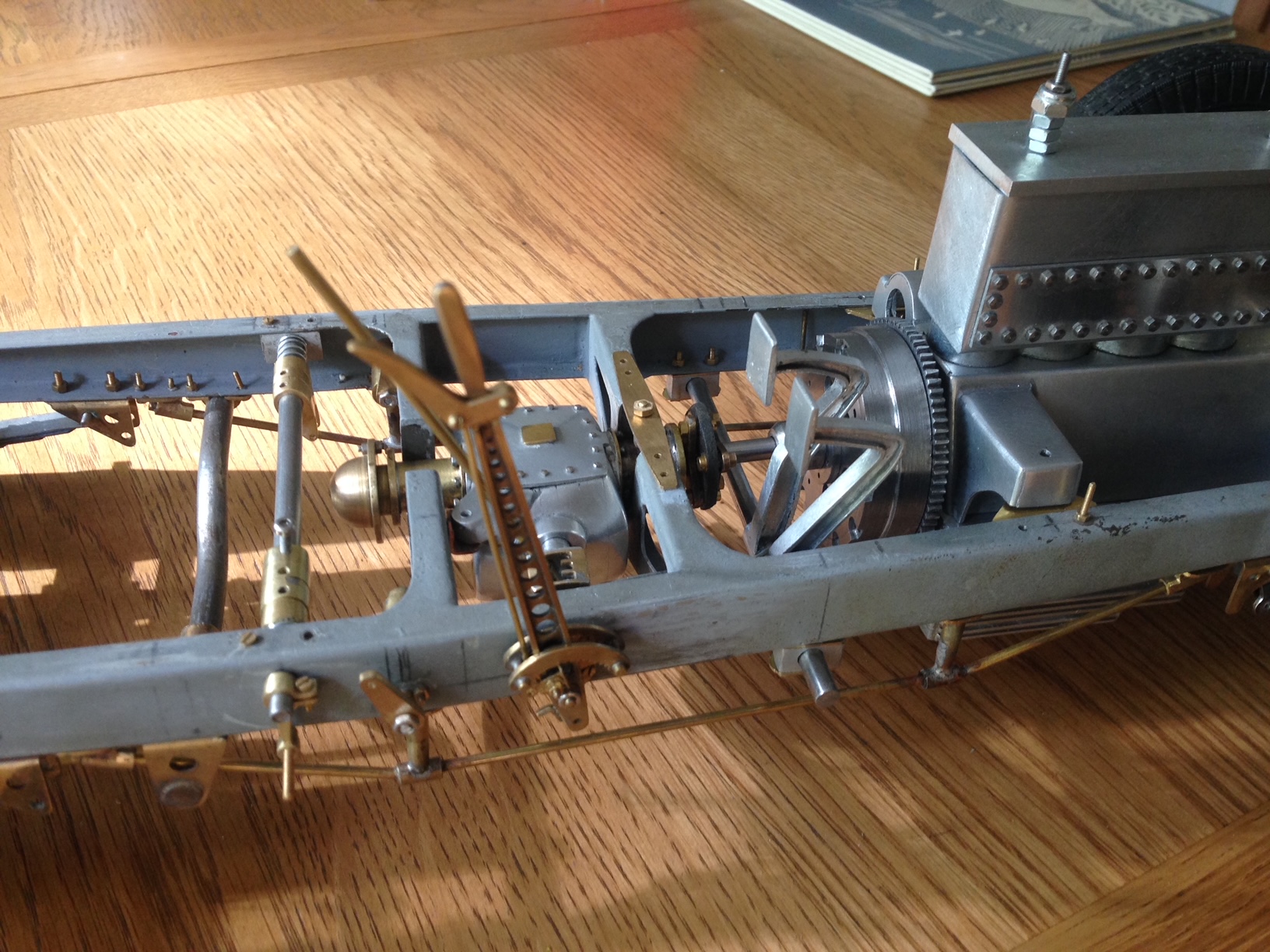

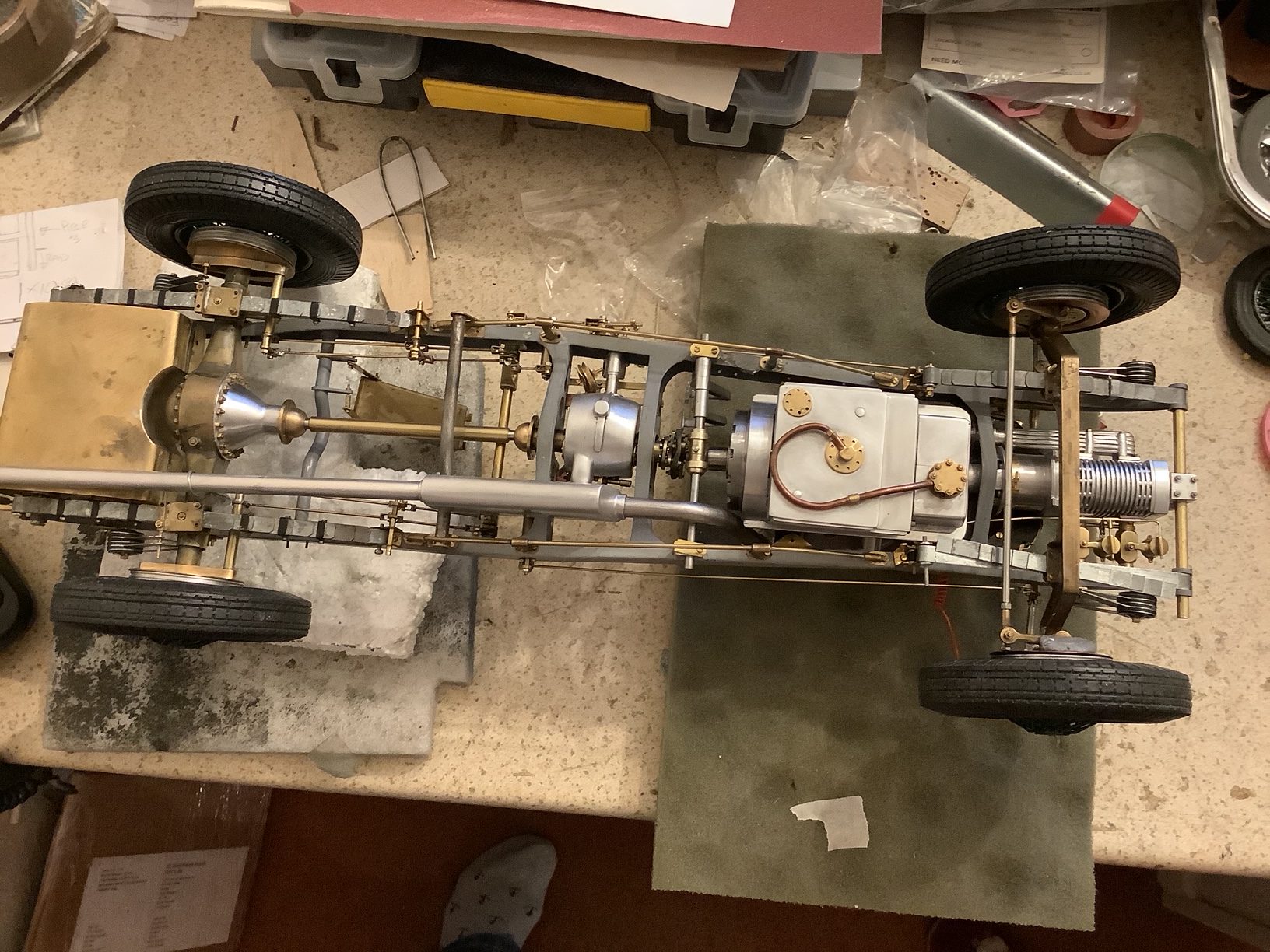

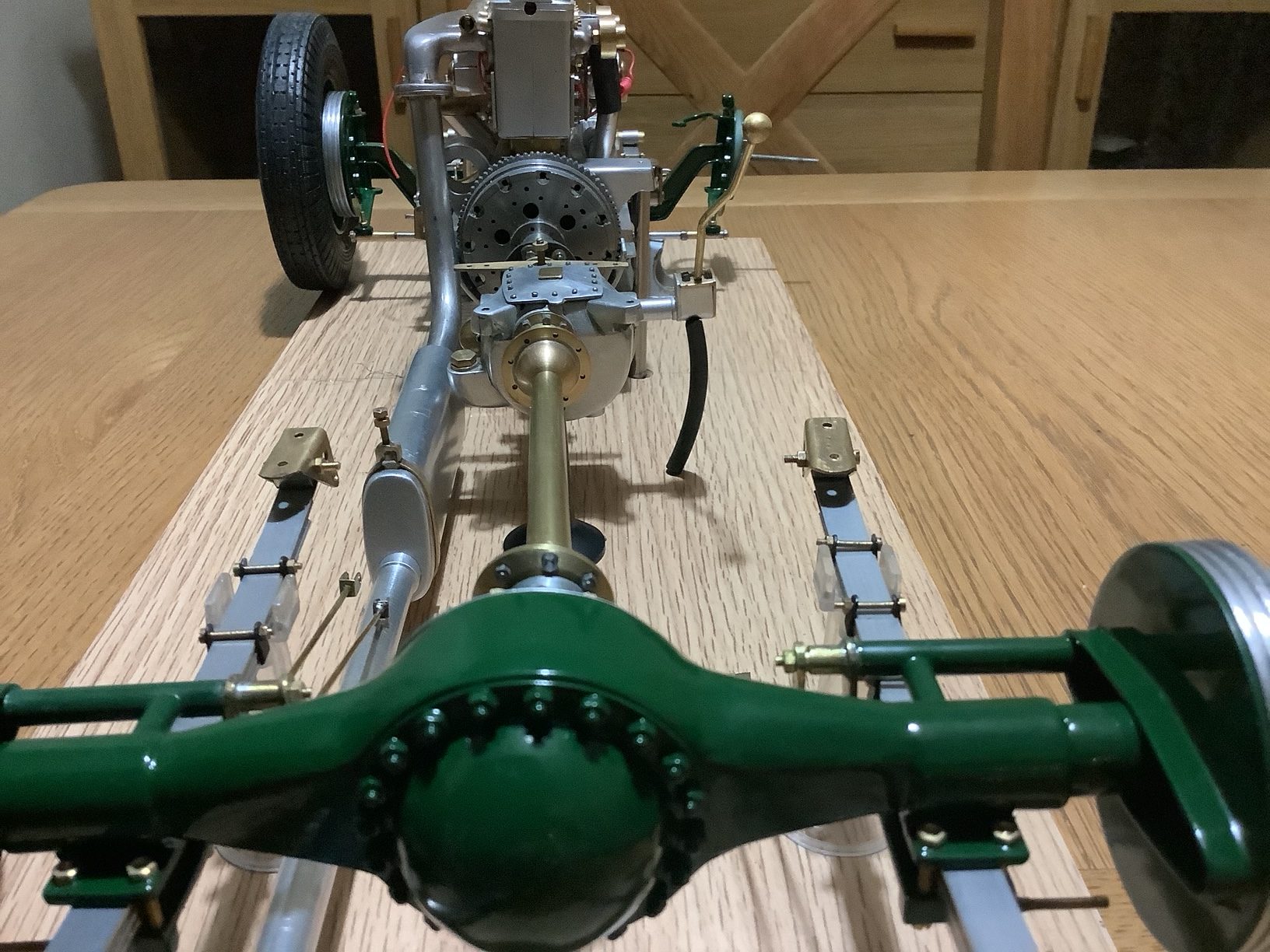

Back axle is made up of brass sheet and tube, with the rear of the differential being a brass clock bell!

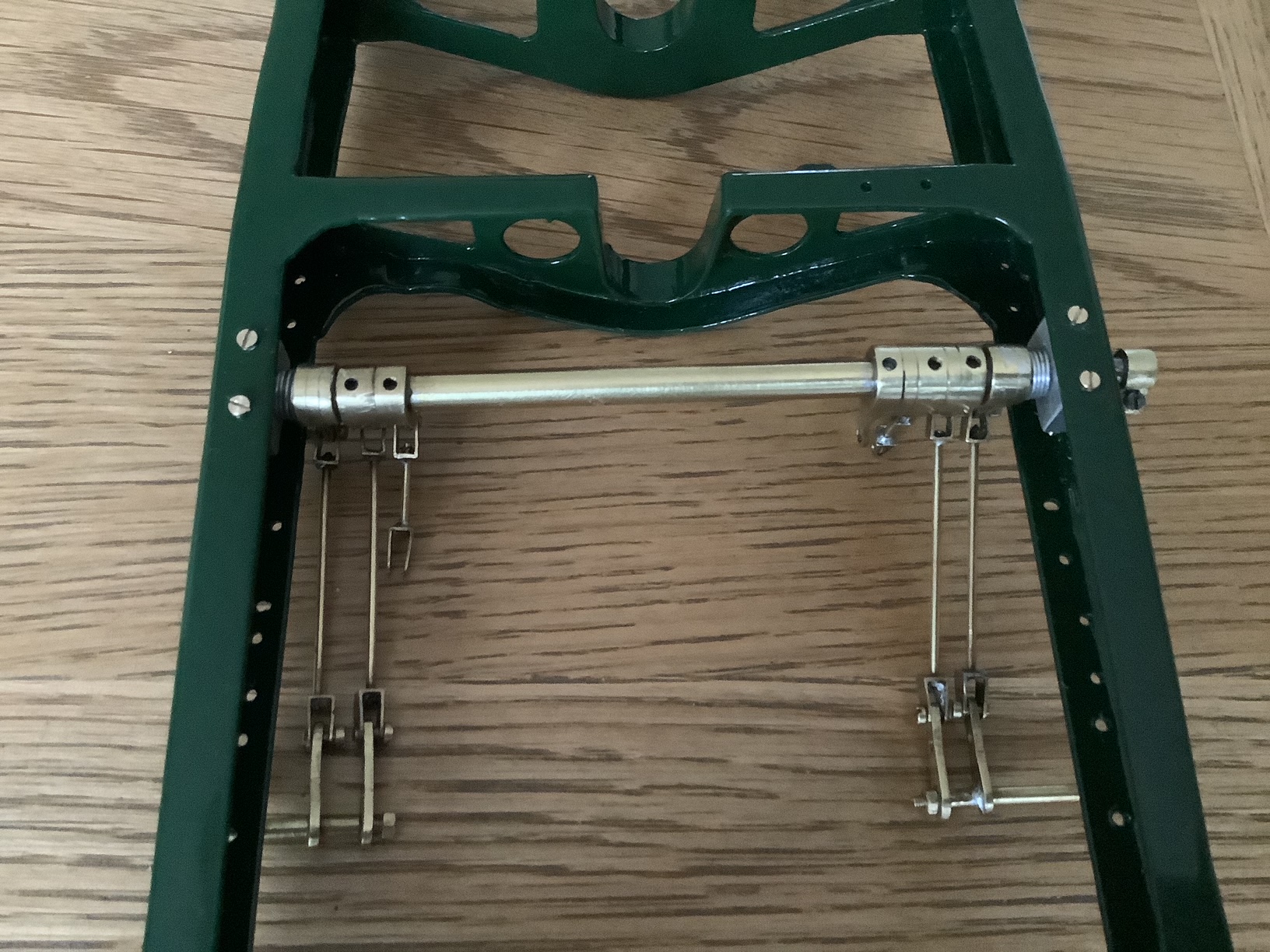

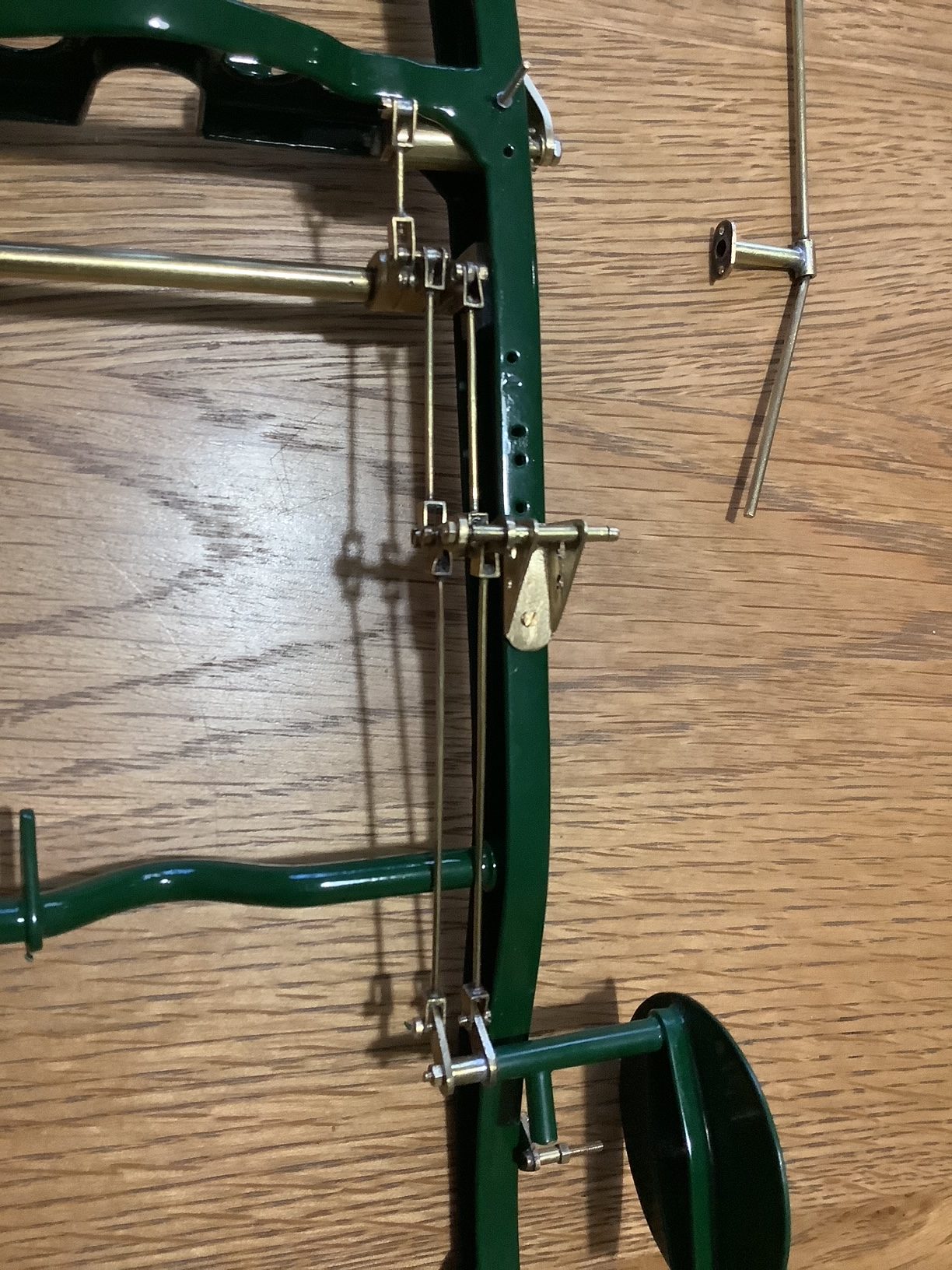

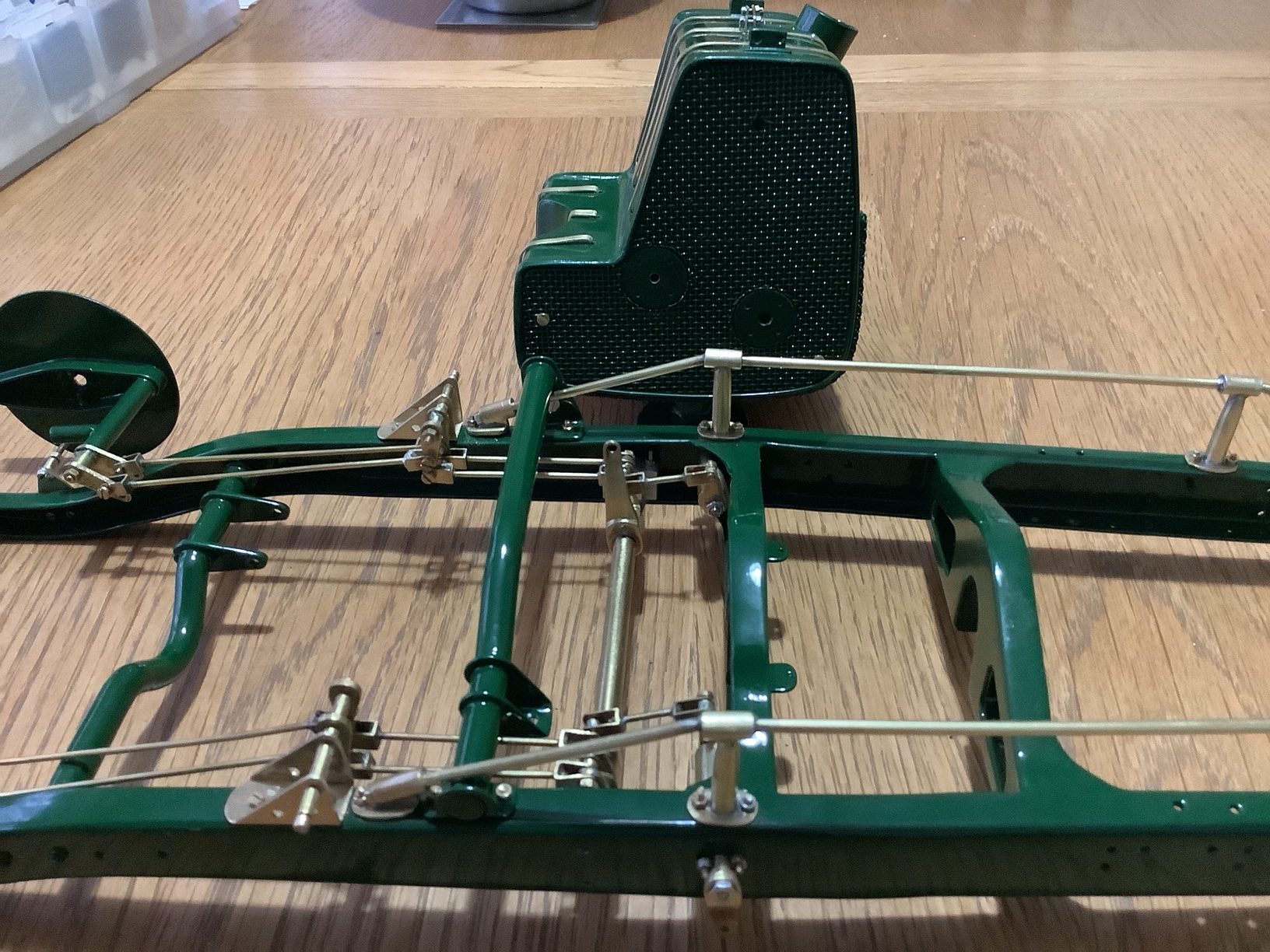

Front axle is all brass sheets, with tube soldered in to take the kingpins.

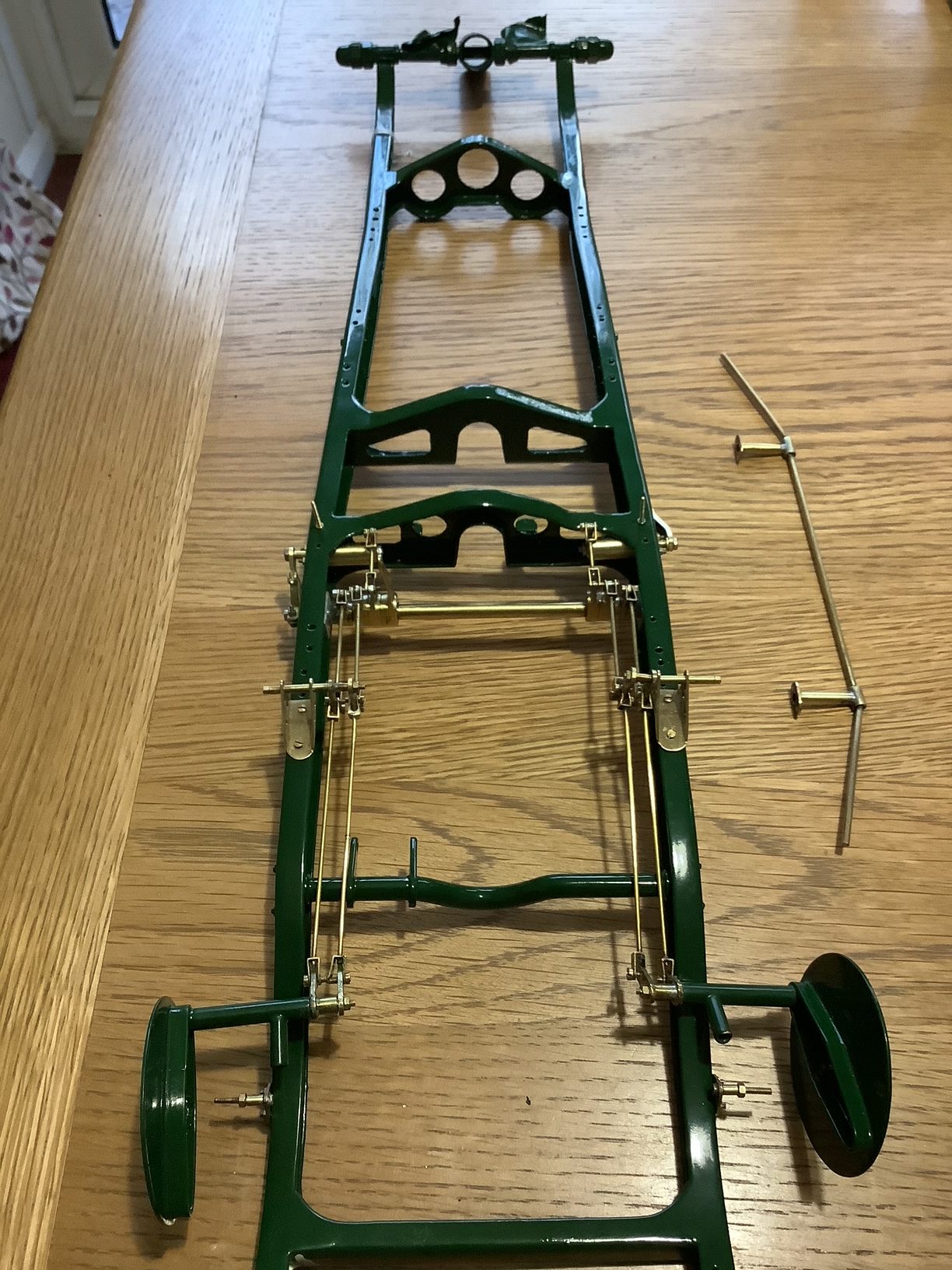

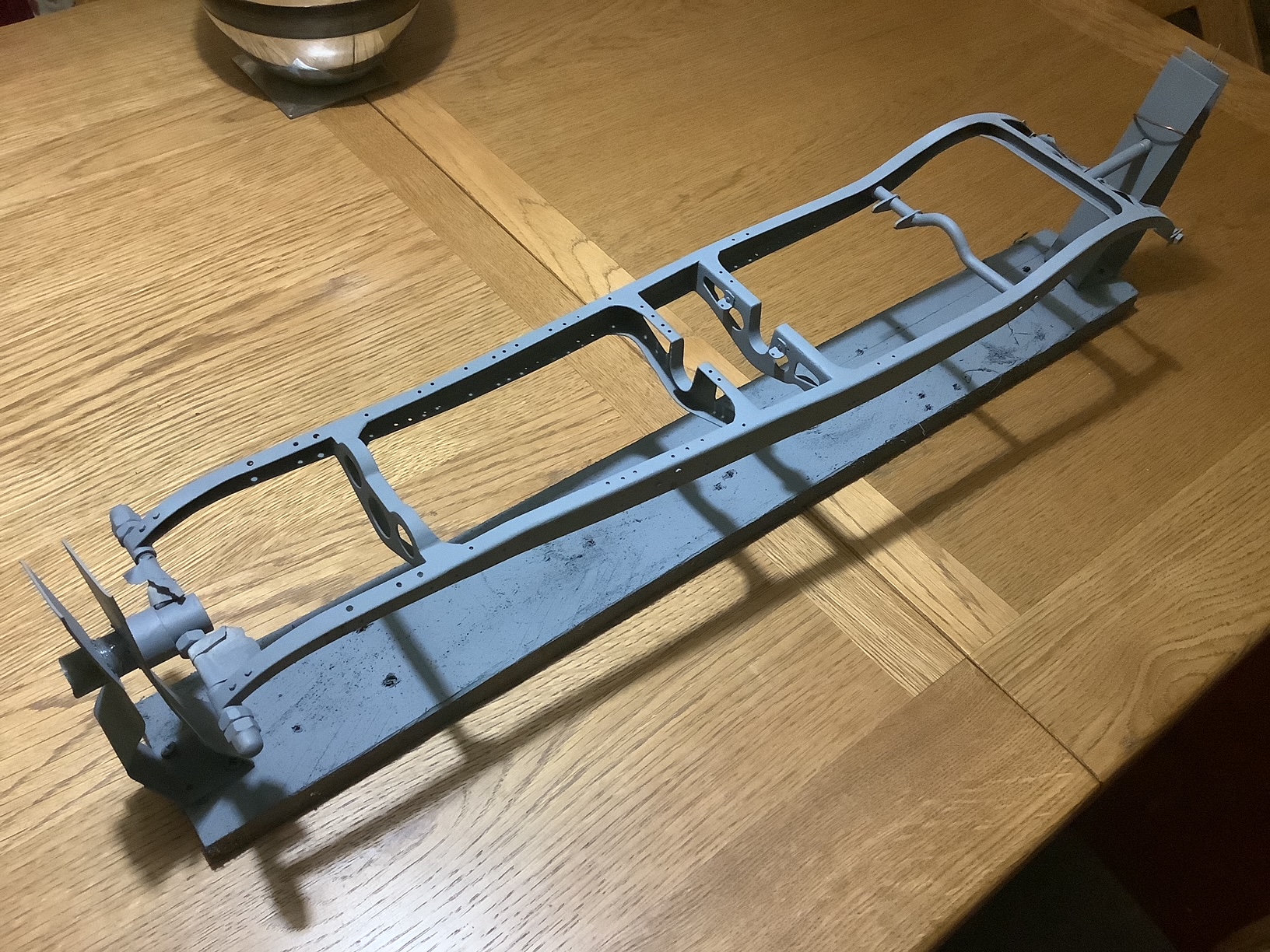

For the chassis I used the steel backbone from an ironing board, this had to be narrowed in some places and then bent into shape. Only a few inches of the original profile remained.

Cross members steel sheet silver soldered into place.

Fuel tank is of 0.5mm brass sheet, with 0.75 brass ends.

The headlamp bowls are actually cut down tea scoops; with the brass brackets riveted on, the rims are heavily modified brass curtain rings.

I hope you like the effect of natural metal against the green, I wanted a sculptural effect, that would both compliment, but at the same time fit in with my Pocher models.

By the time I got to the steering column I finally had a lathe, all I have to do now is learn how to use it! Thank you all for your interest.

You must be logged in to post a comment.