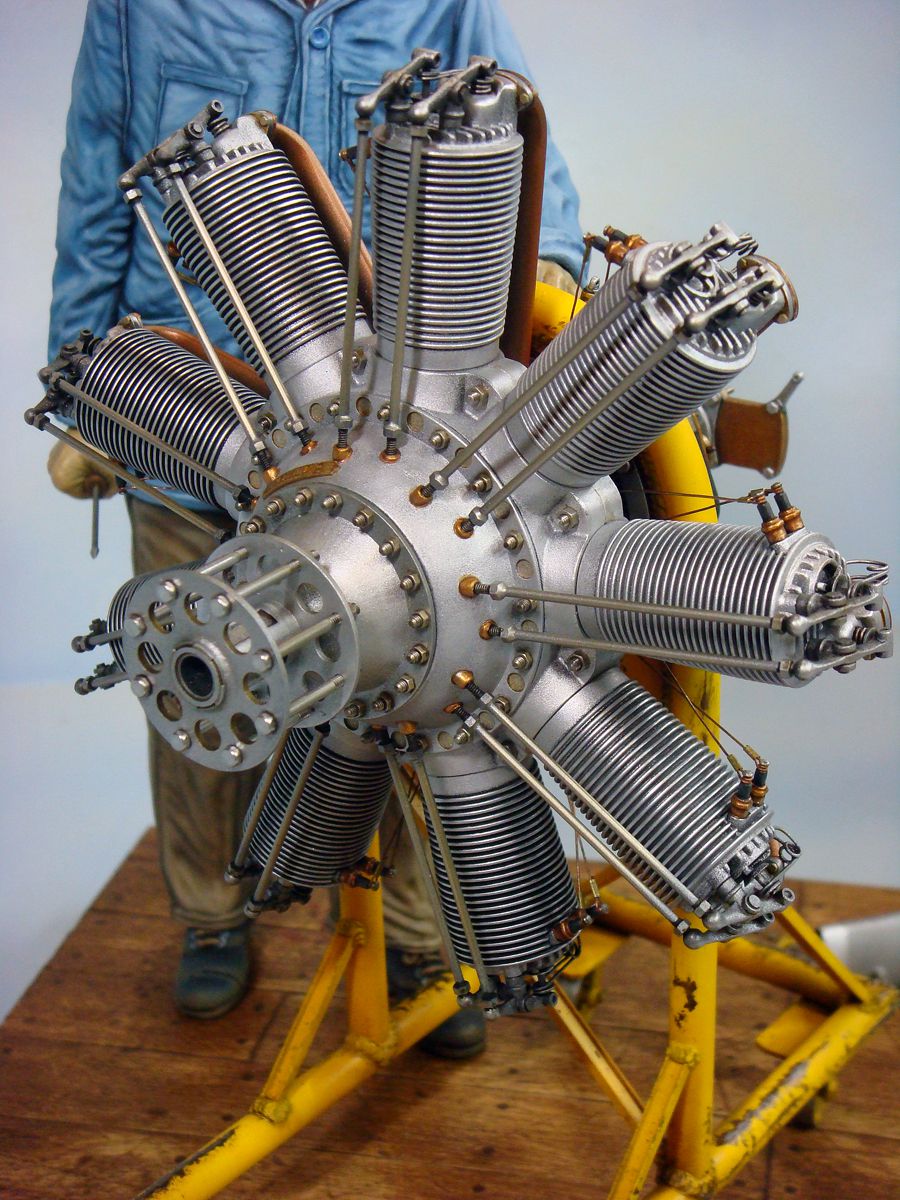

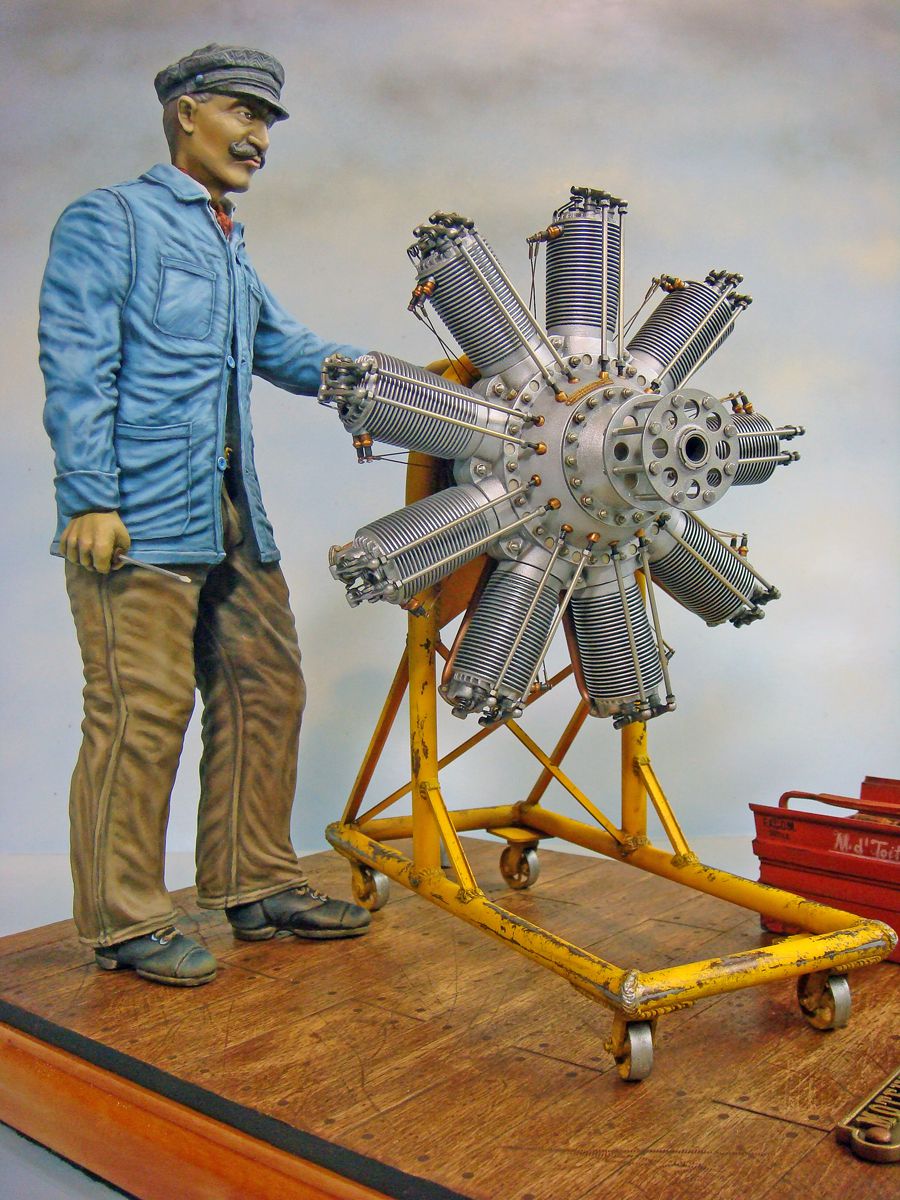

Mike Roof's

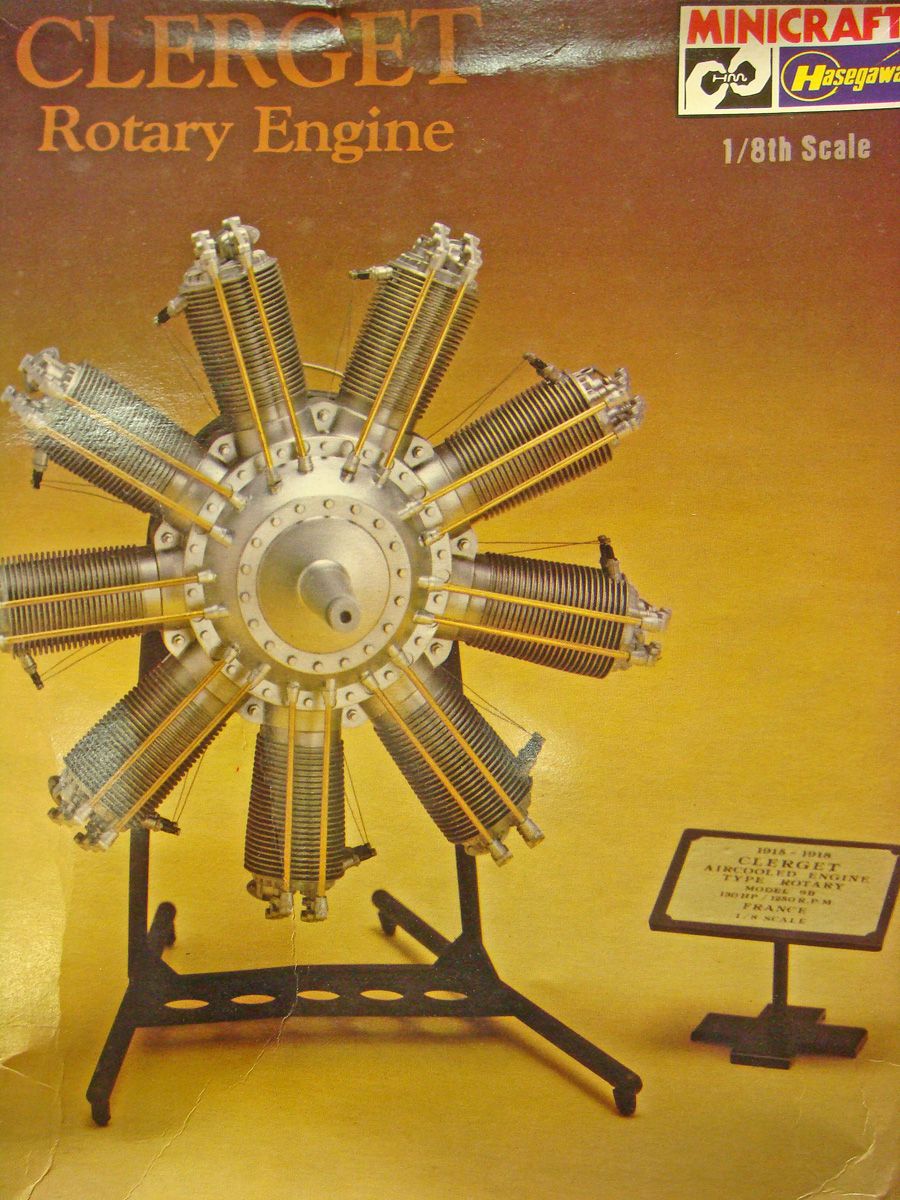

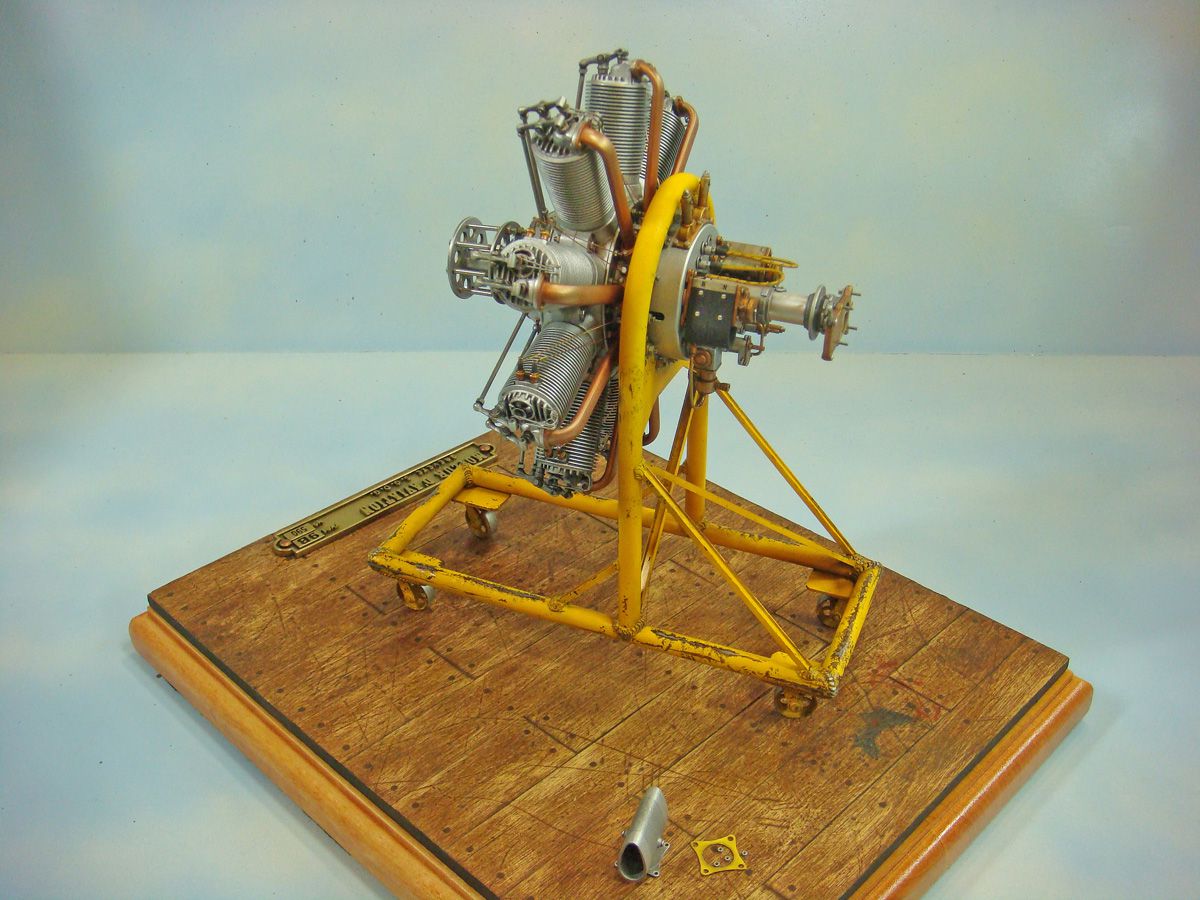

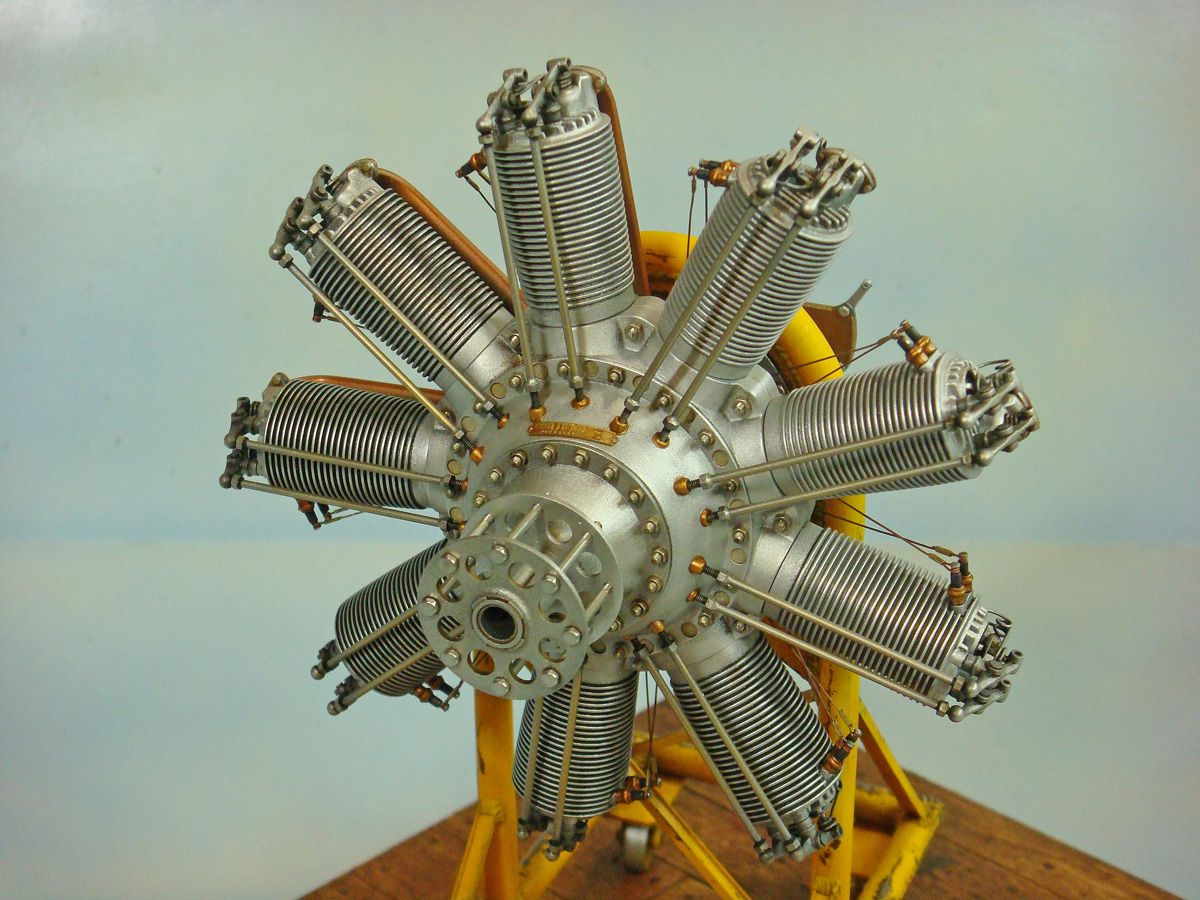

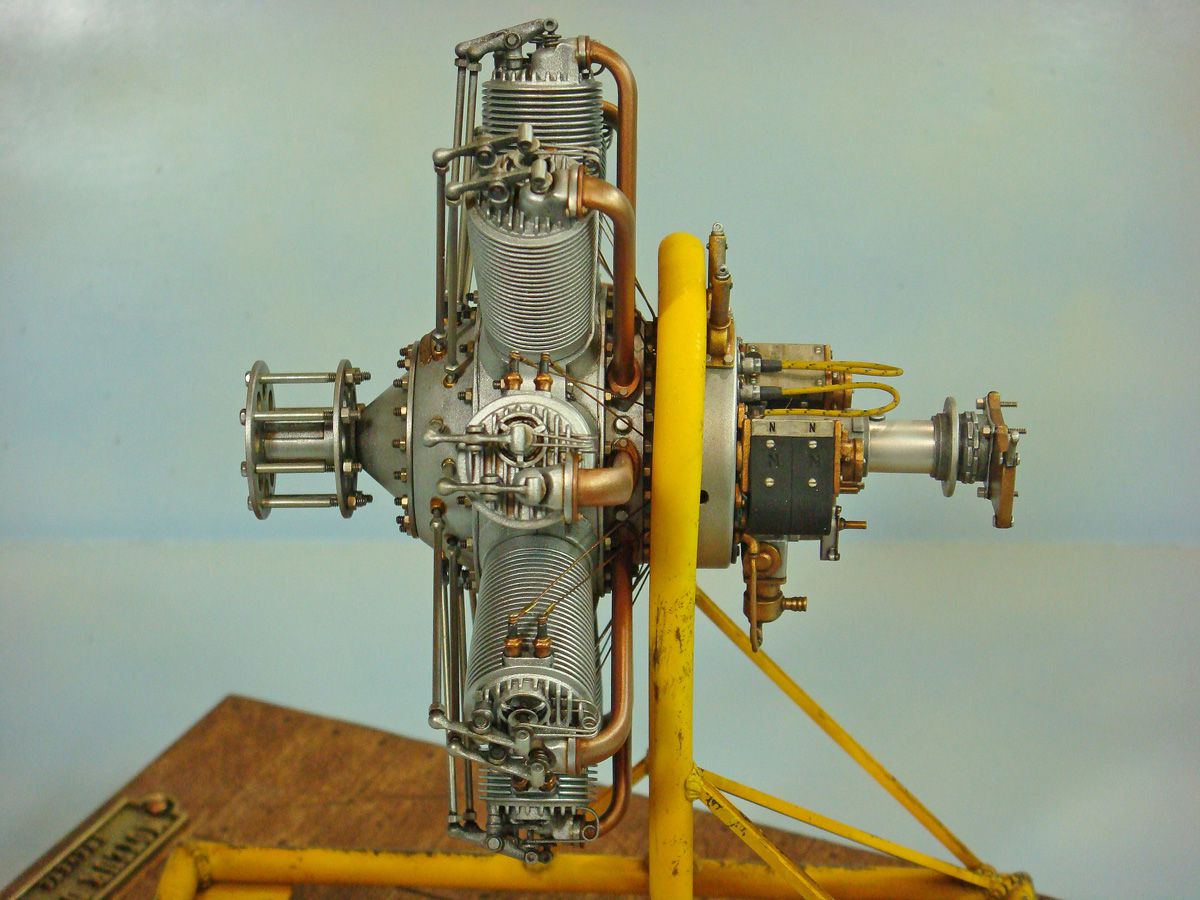

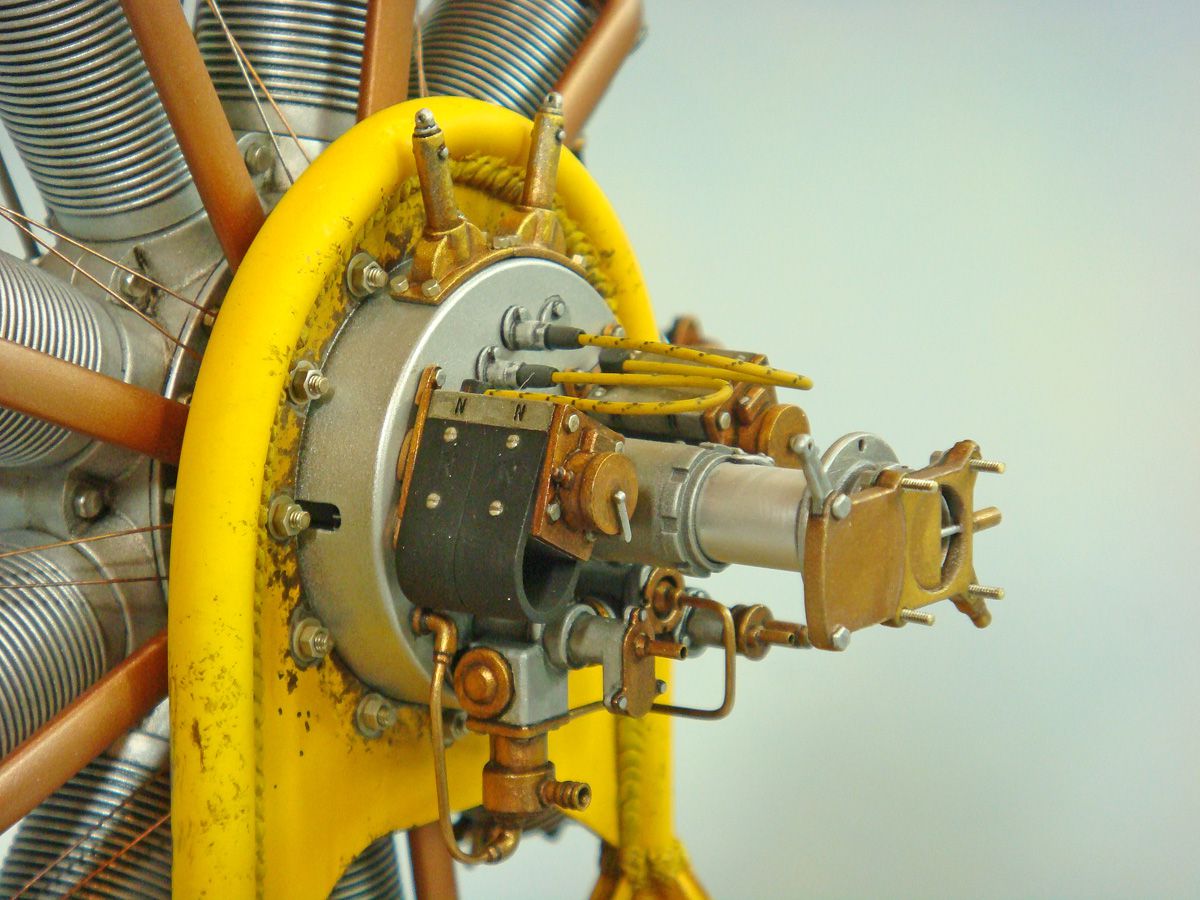

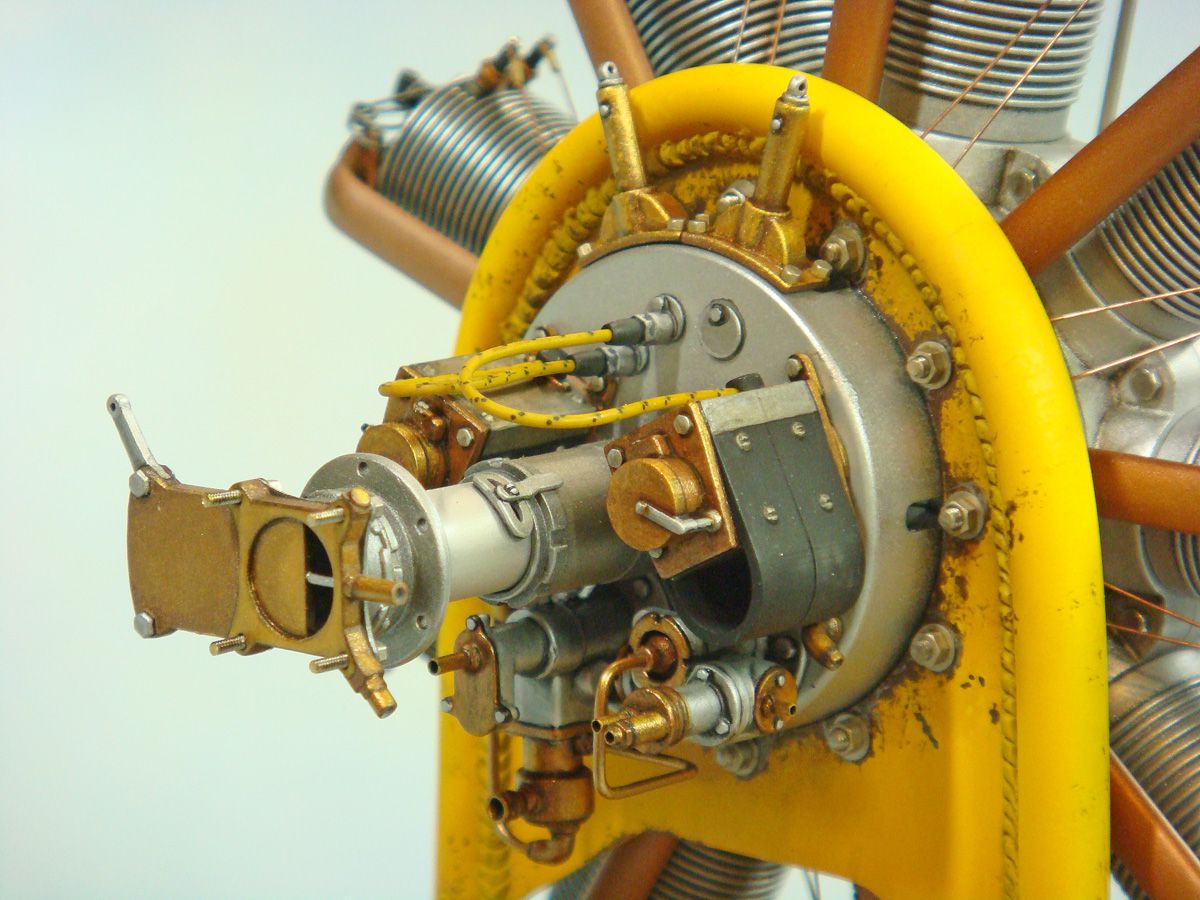

Minicraft / Hasegawa 1/8 Scale “Clerget 9B” Rotary Engine

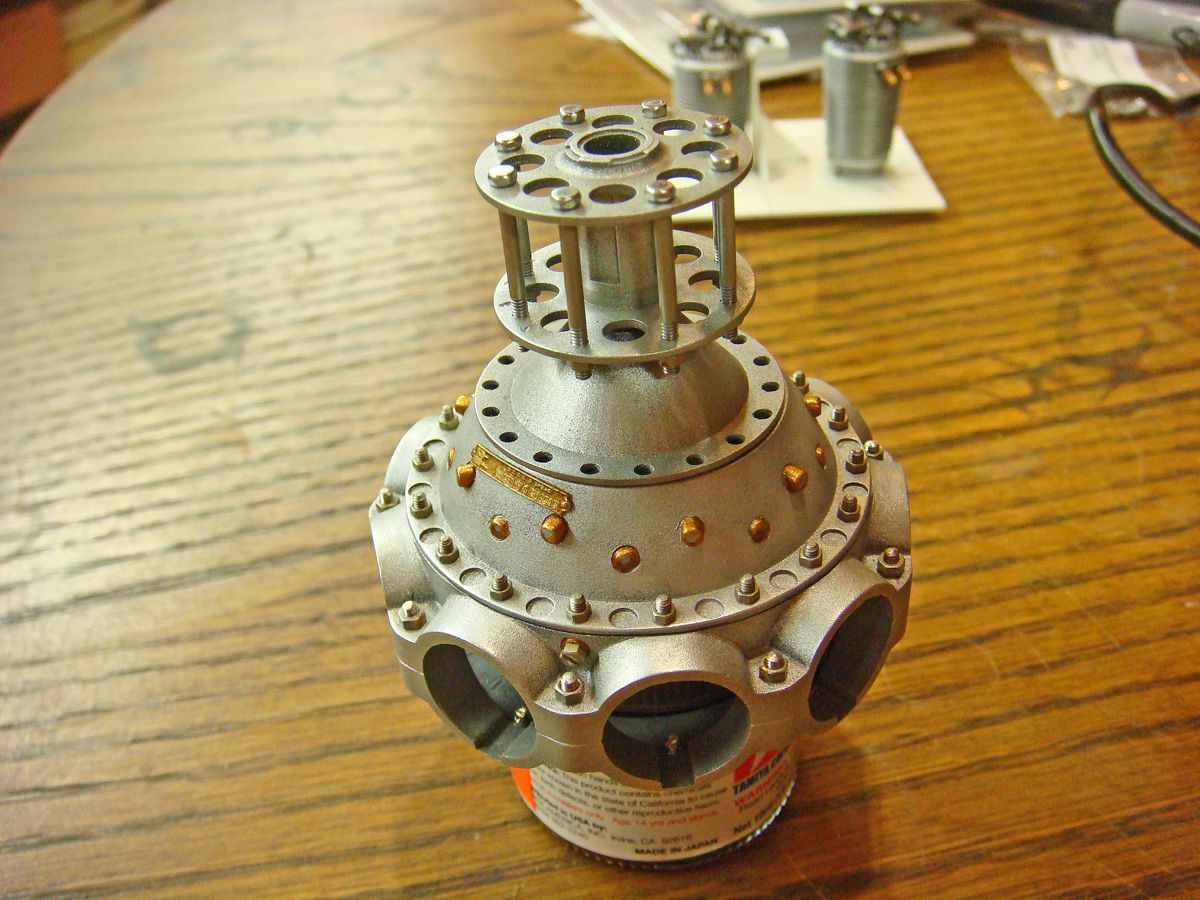

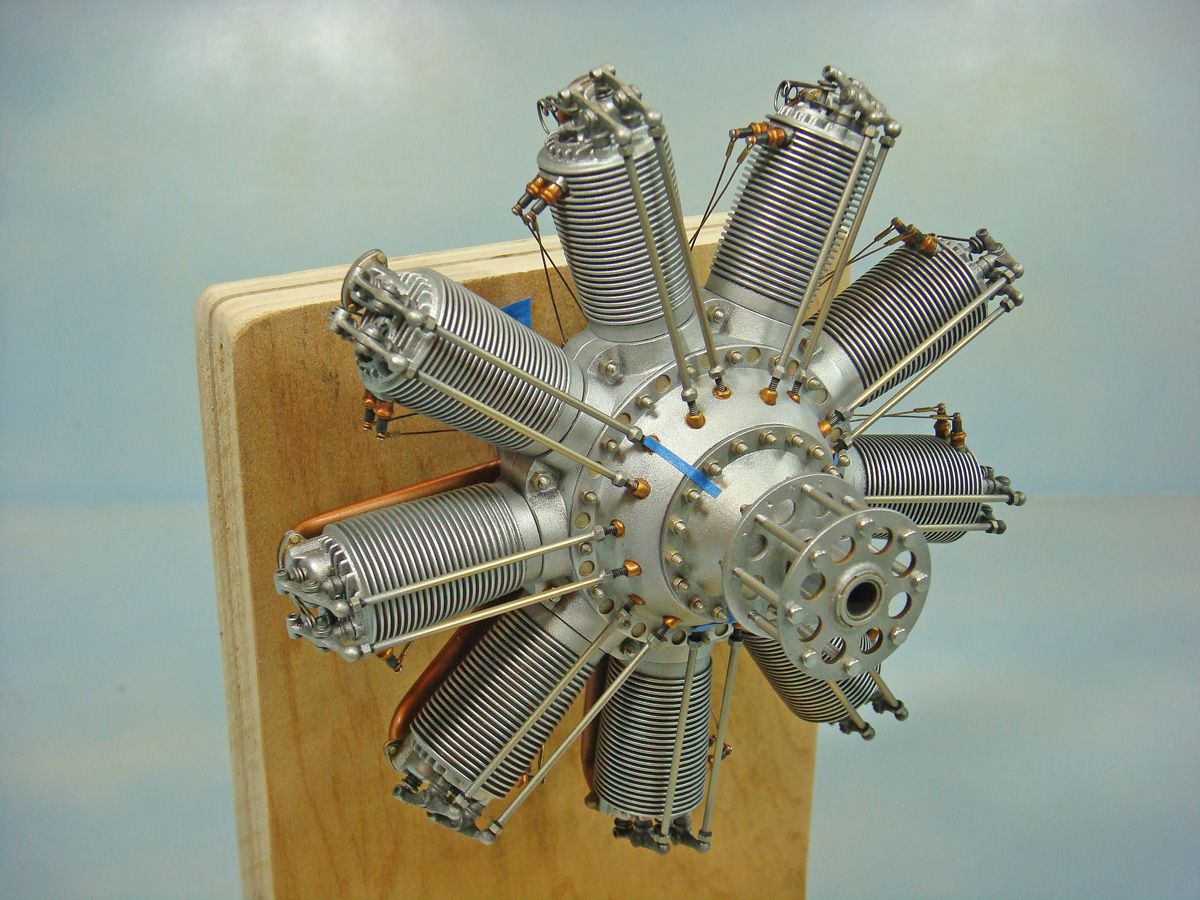

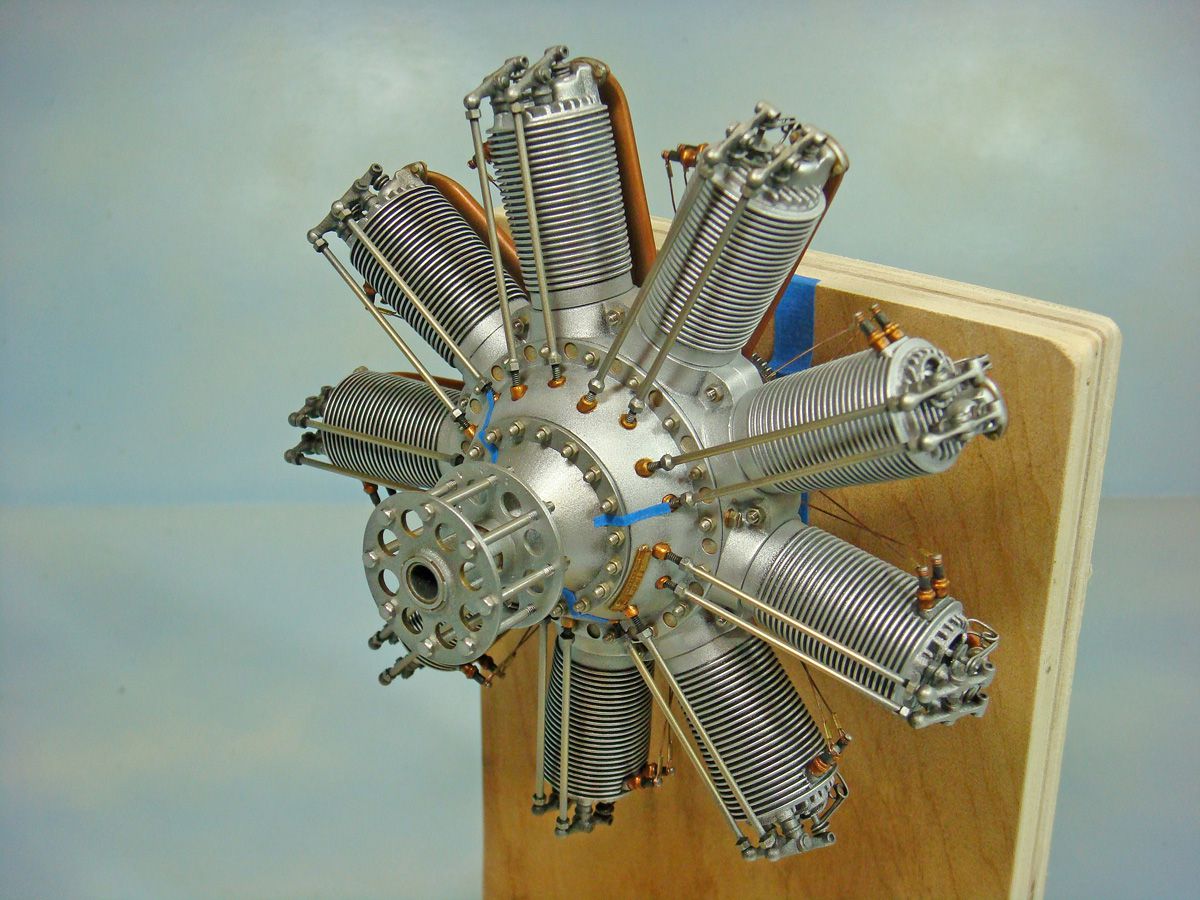

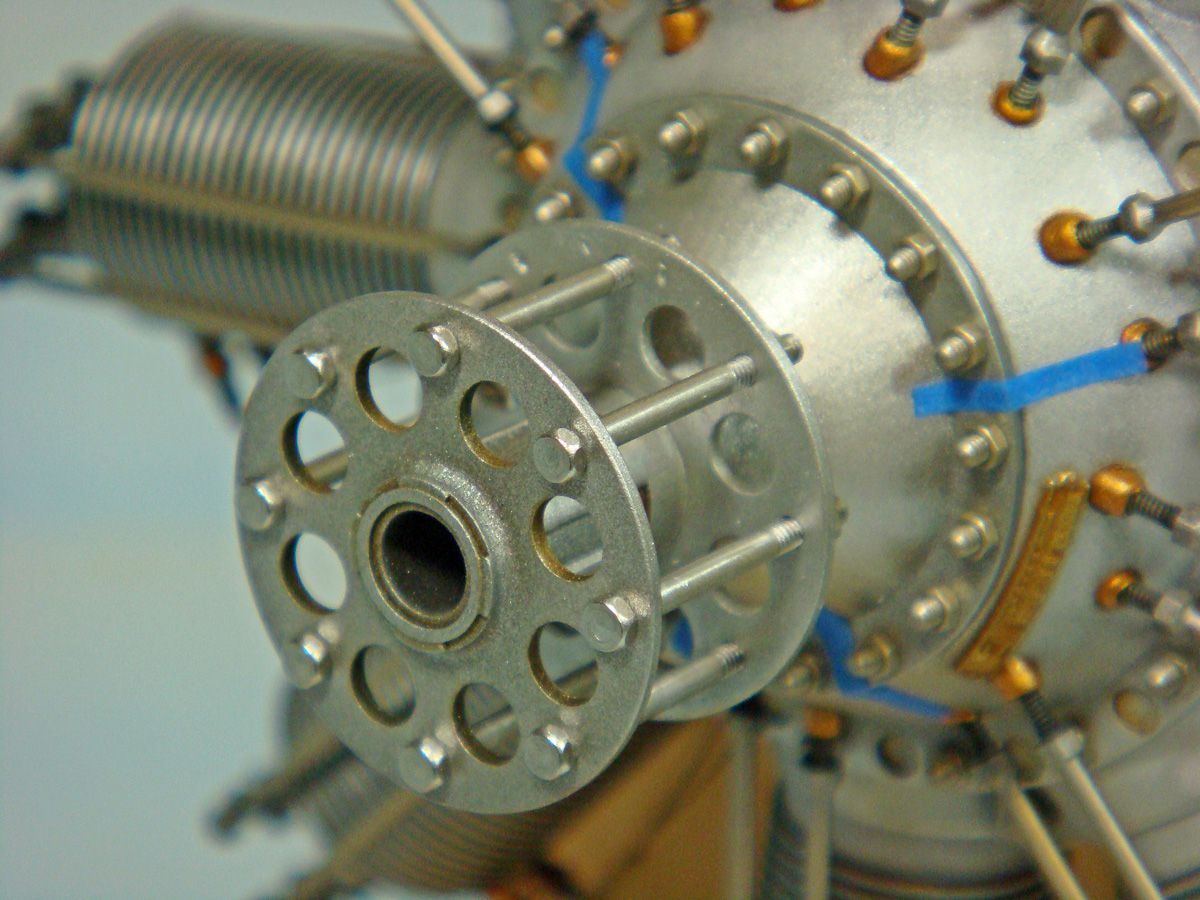

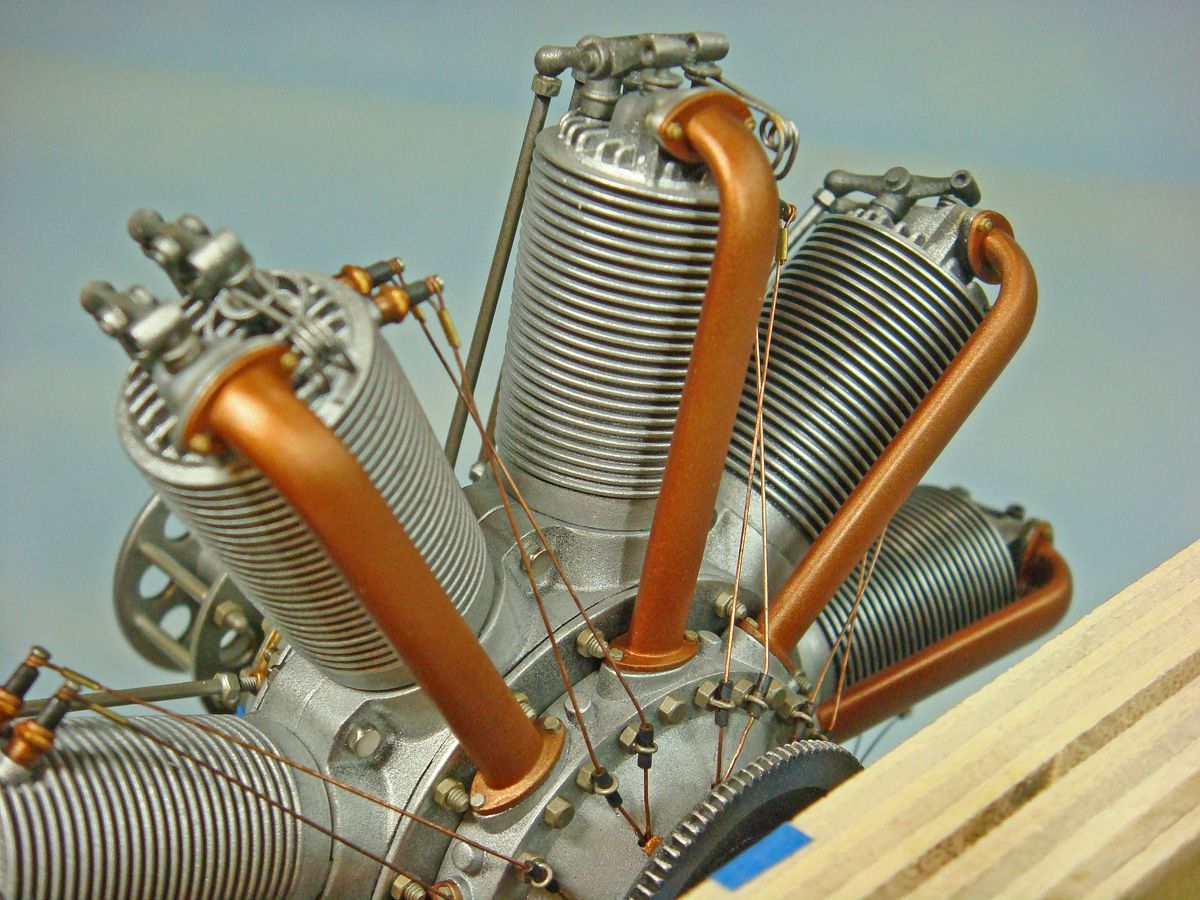

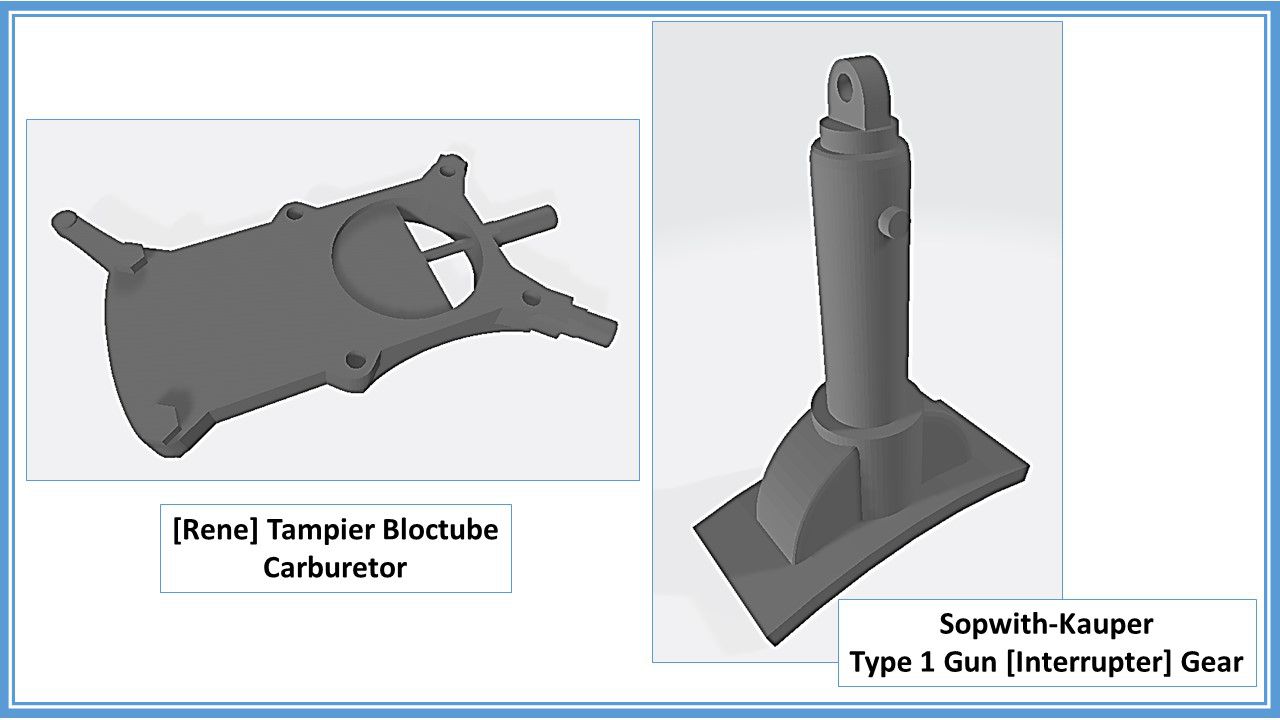

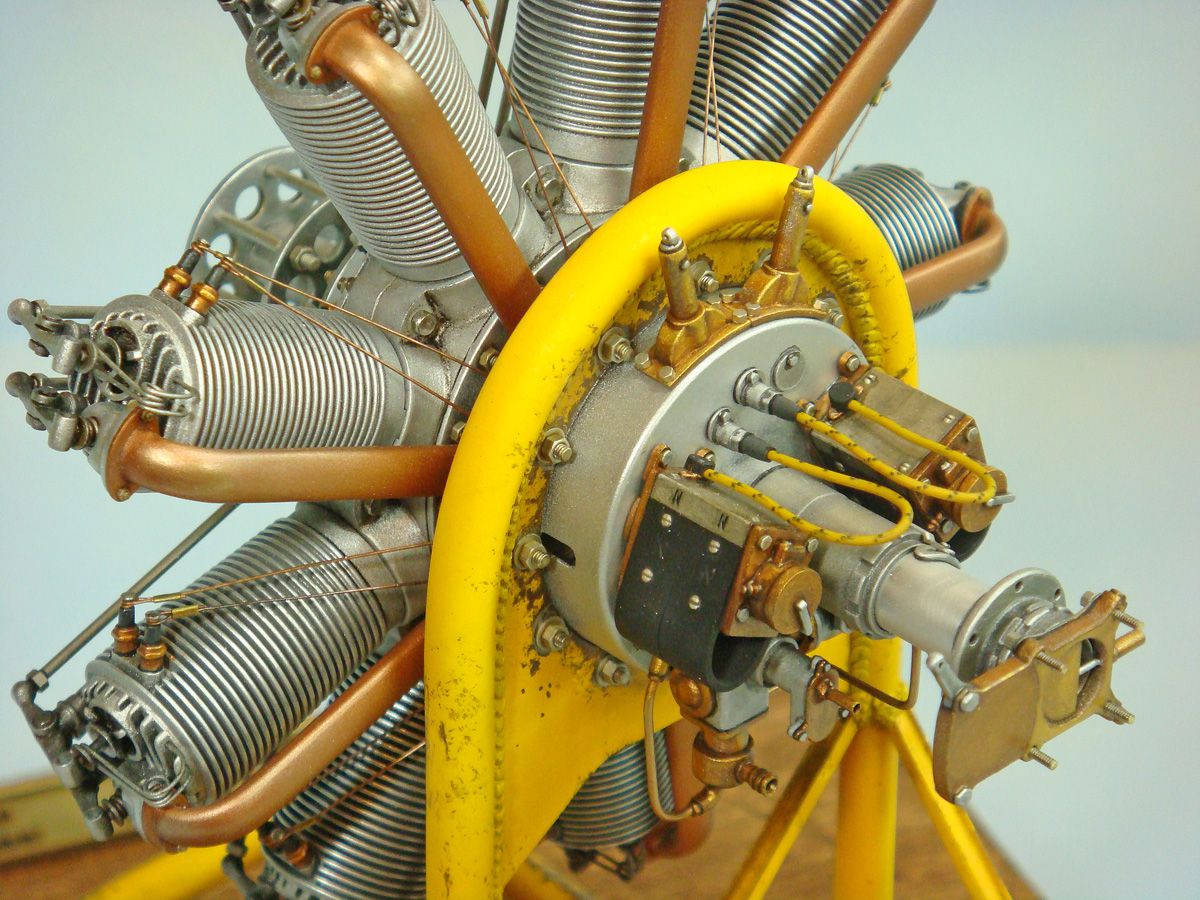

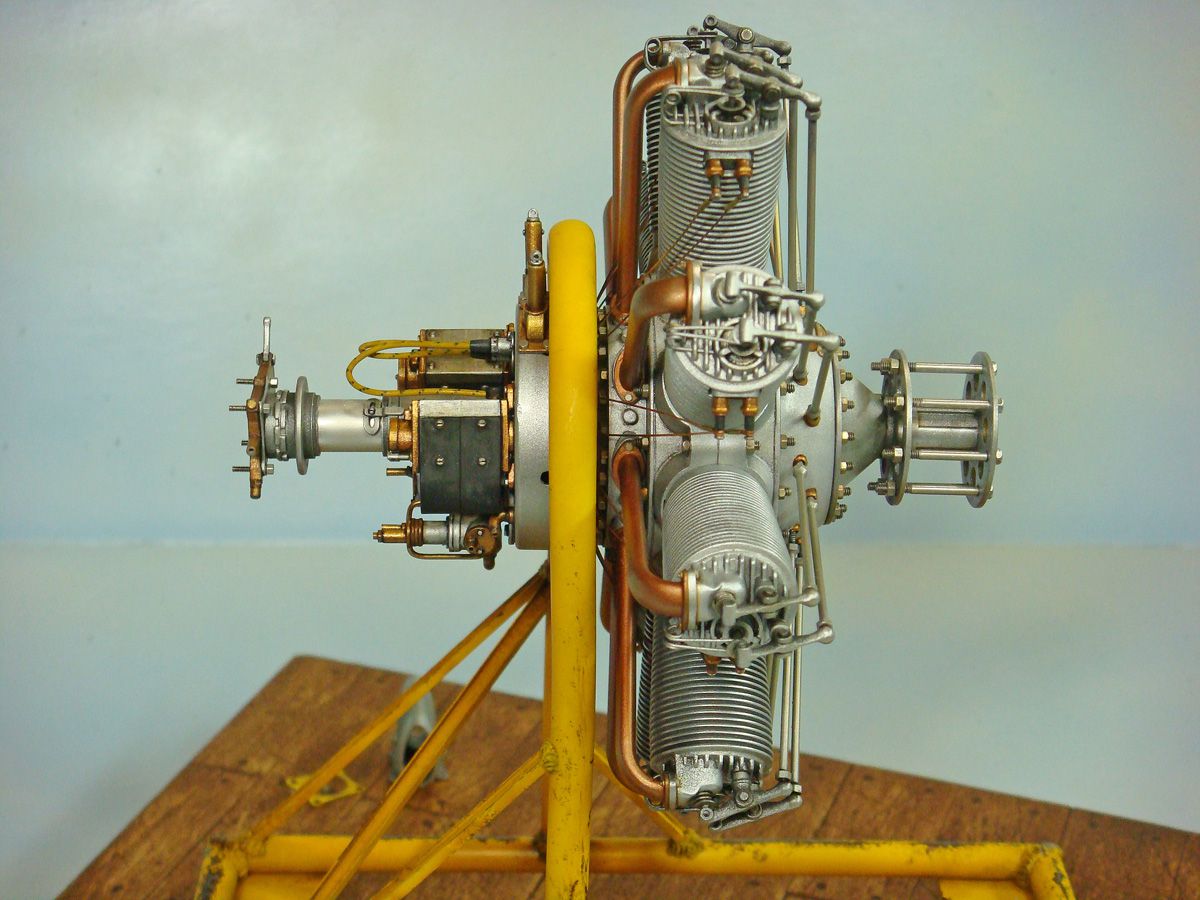

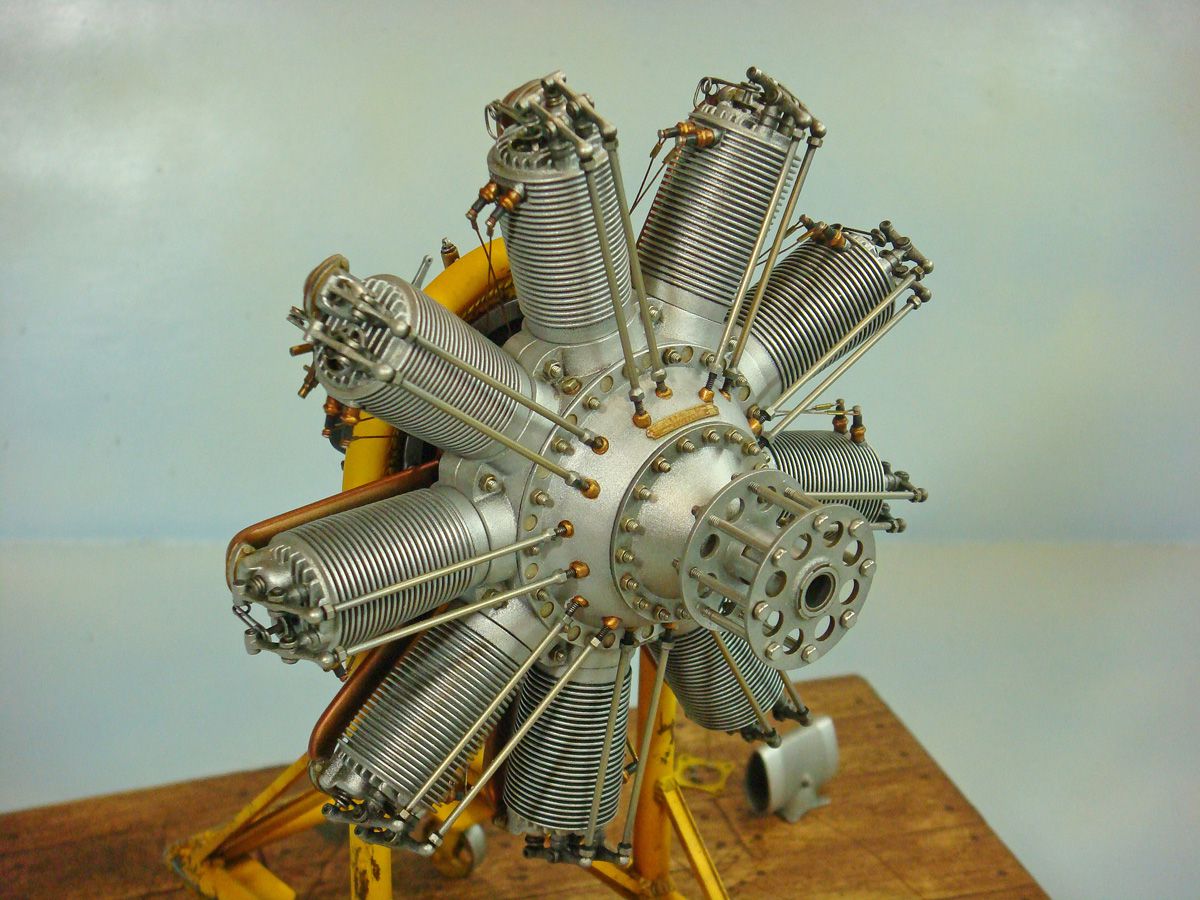

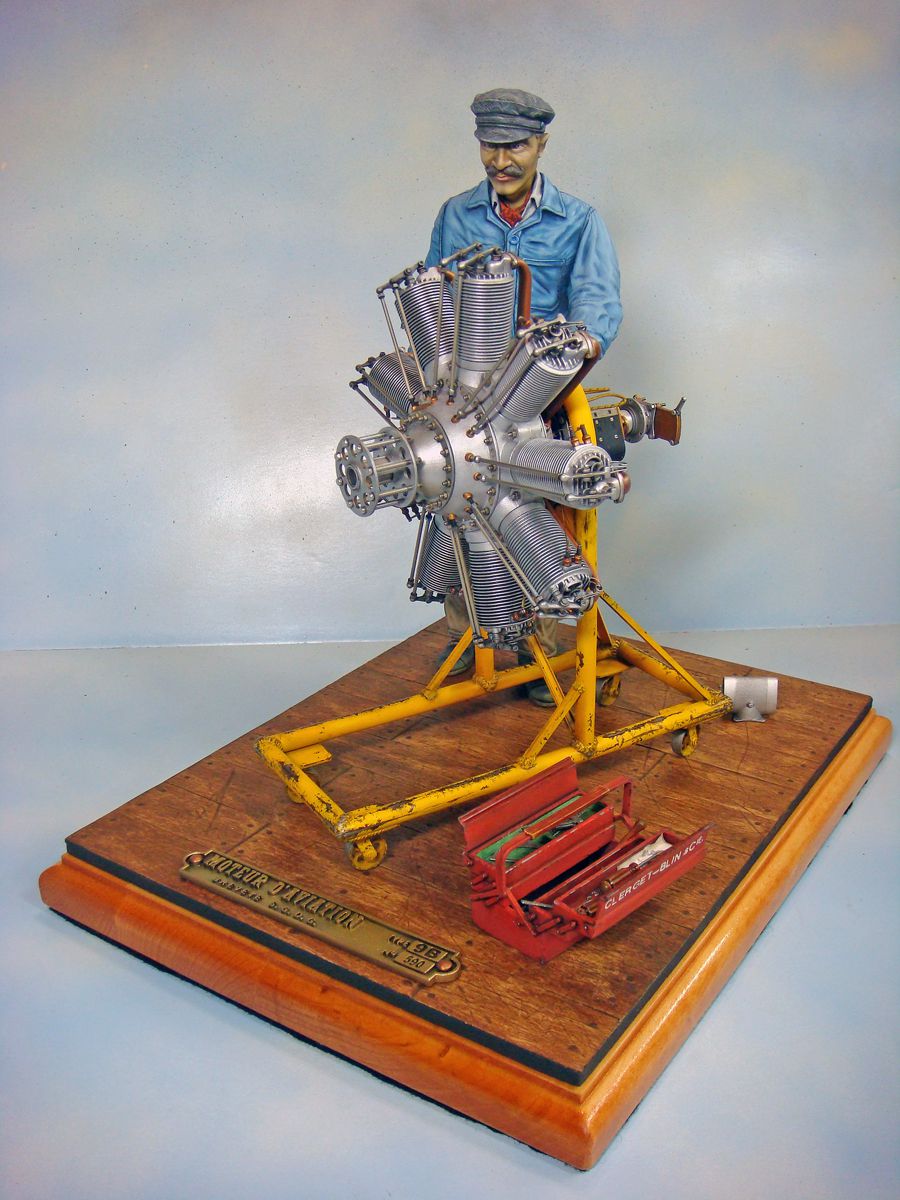

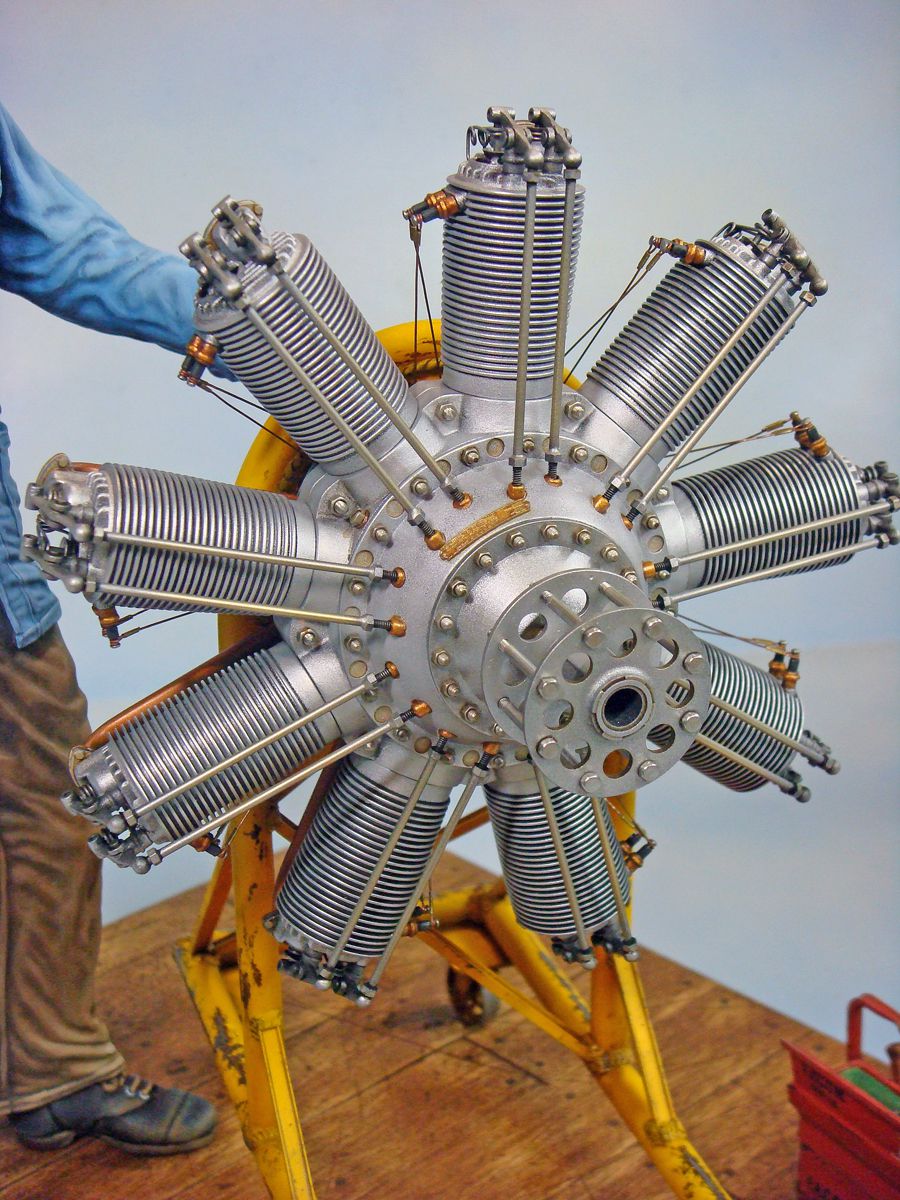

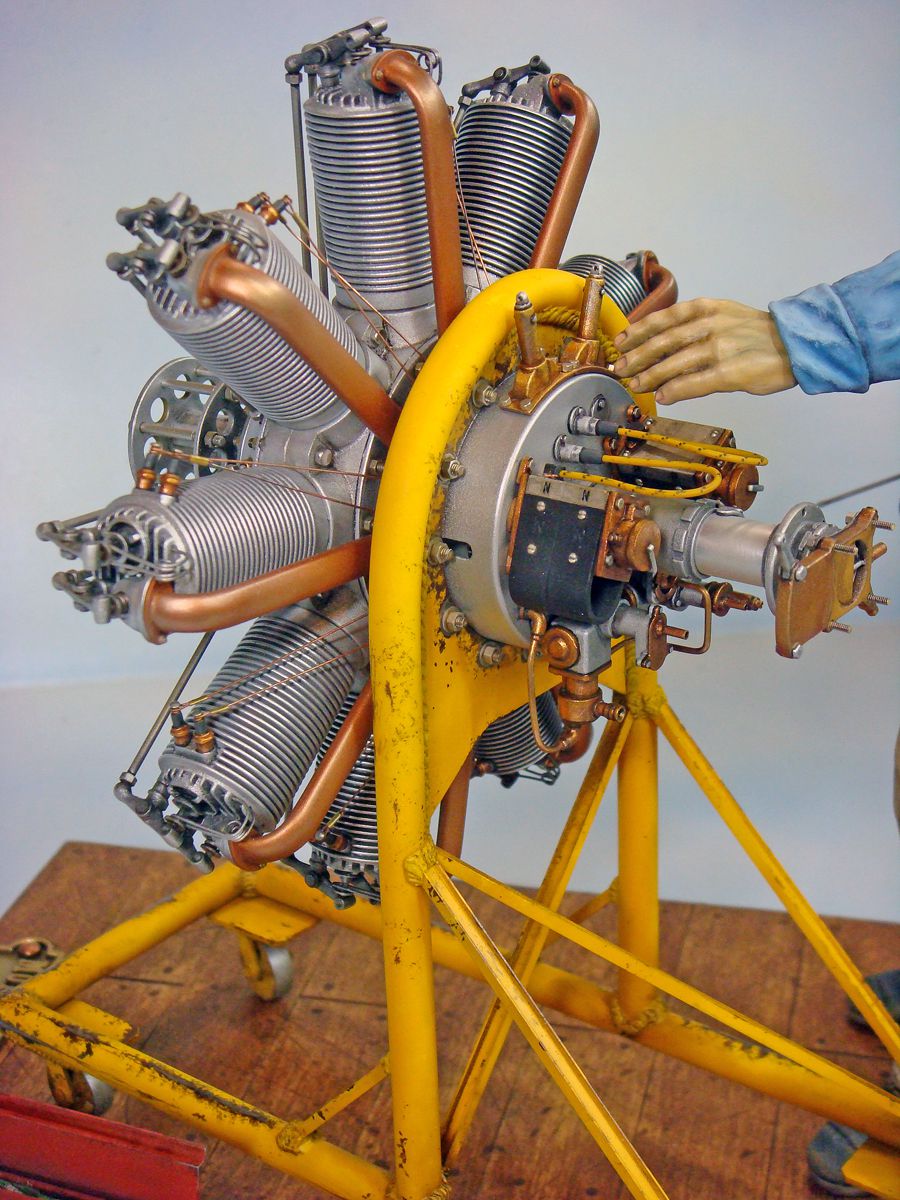

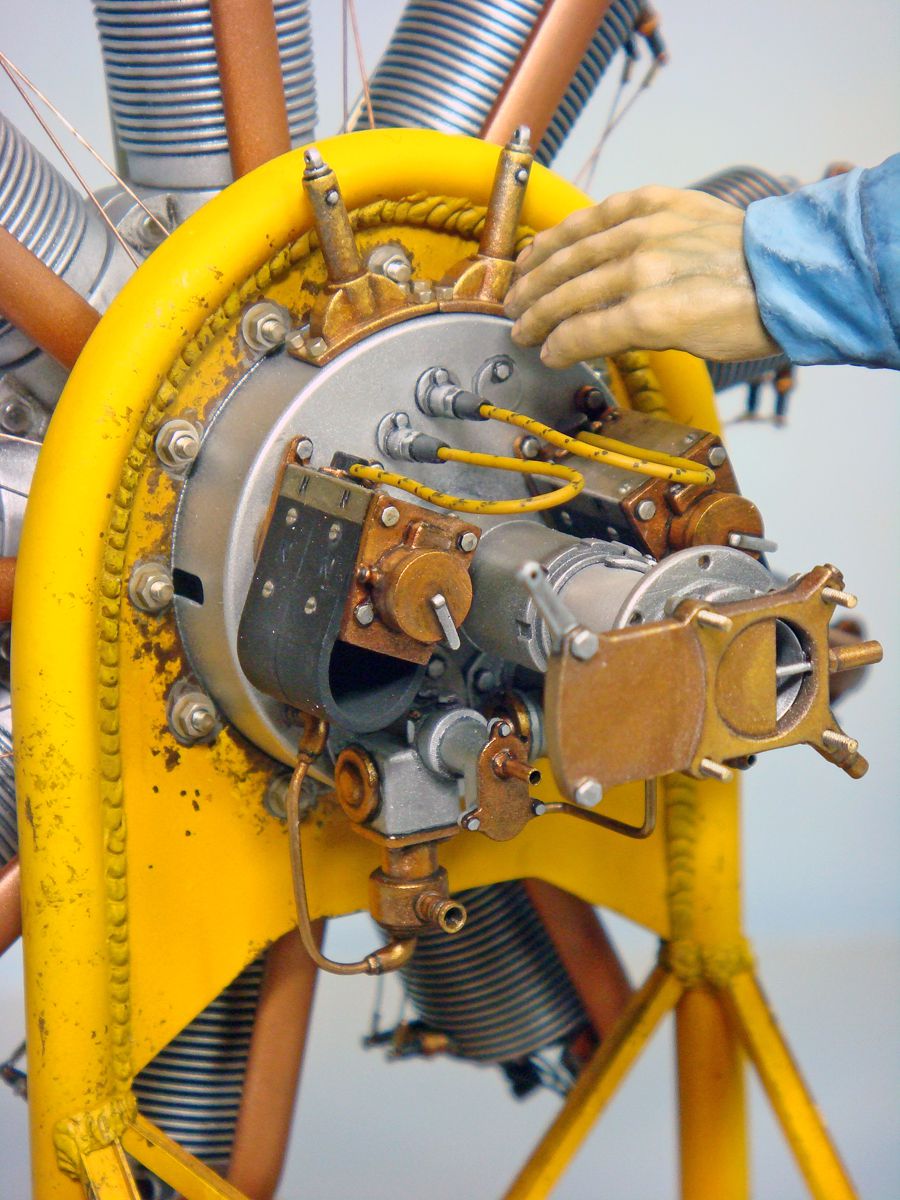

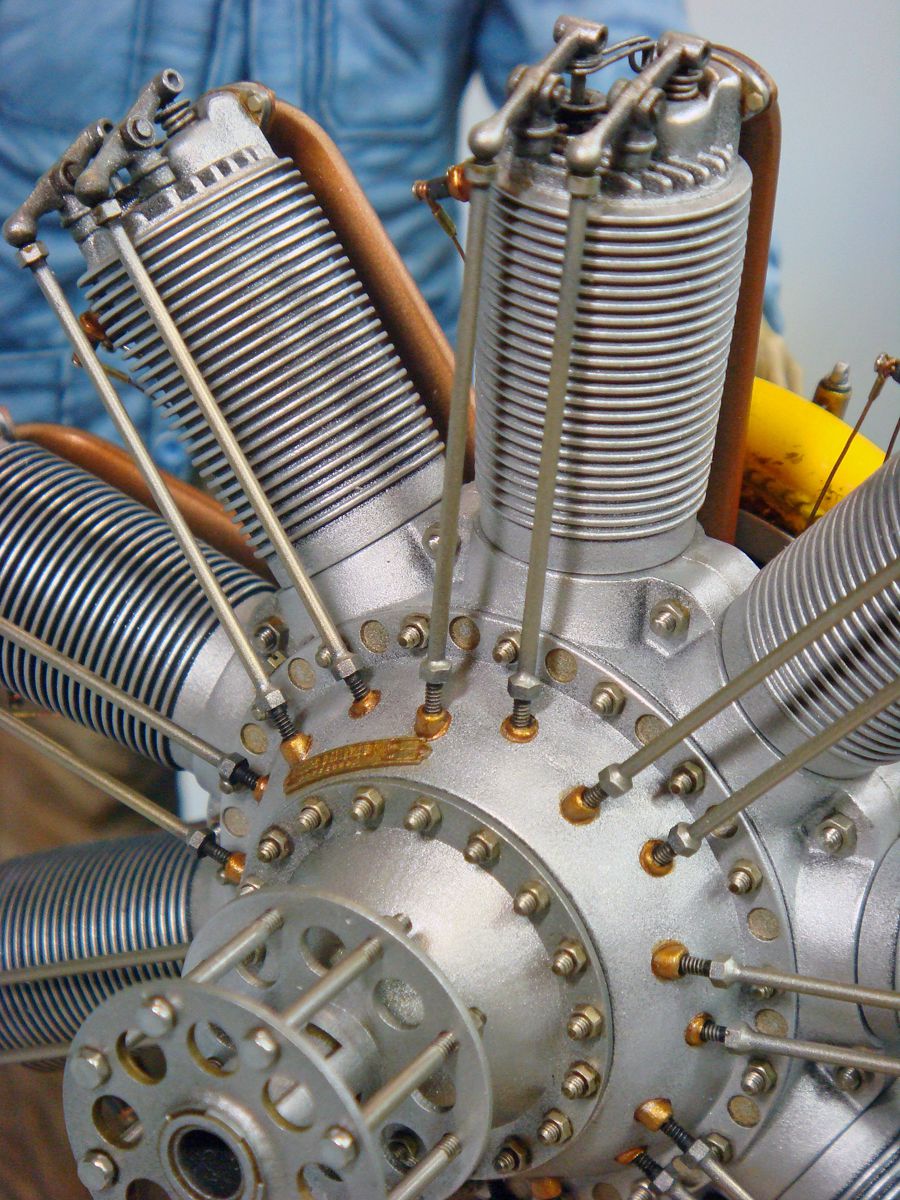

The Hasegawa 1/8 scale Clerget 9b Rotary Engine was originally issued around 1986, and since then has seen several re-boxings with the latest coming out ca. 2011. It’s not a “bad” kit, but it was and still is a bit dated and over-simplified. The original engine was rated at about 130 hp. and was used on the famous Sopwith Camel of WWI. Despite its appearance, it’s not a radial-type engine, but rather a rotary-type in which the entire crankcase and the cylinders rotate with the attached propeller. The Clerget 9B also employed a total loss oil system that injected castor oil into the air-fuel mix in order to lubricate the internals (with the crankcase acting as the intake manifold and the exhaust ported directly from the cylinder heads). Castor oil was less soluble in the aviation gasoline, so it retained its lubricating properties better than using a petroleum based oil in the same type of system.

With such a large scale, the Hasegawa kit just about cries out for some extra attention and detail. Unfortunately, while there are several partial and complete original engines still held in various museum collections around the world, detailed information is pretty hard to come by. The original engines were also made in several different variants with numerous small detail changes in both France and, under license, in Britain. About the best I could do with my limited resources was to compile as many photos as possible and then make some educated guesses about the evolution of the design during manufacturing along with the changes employed different in applications.

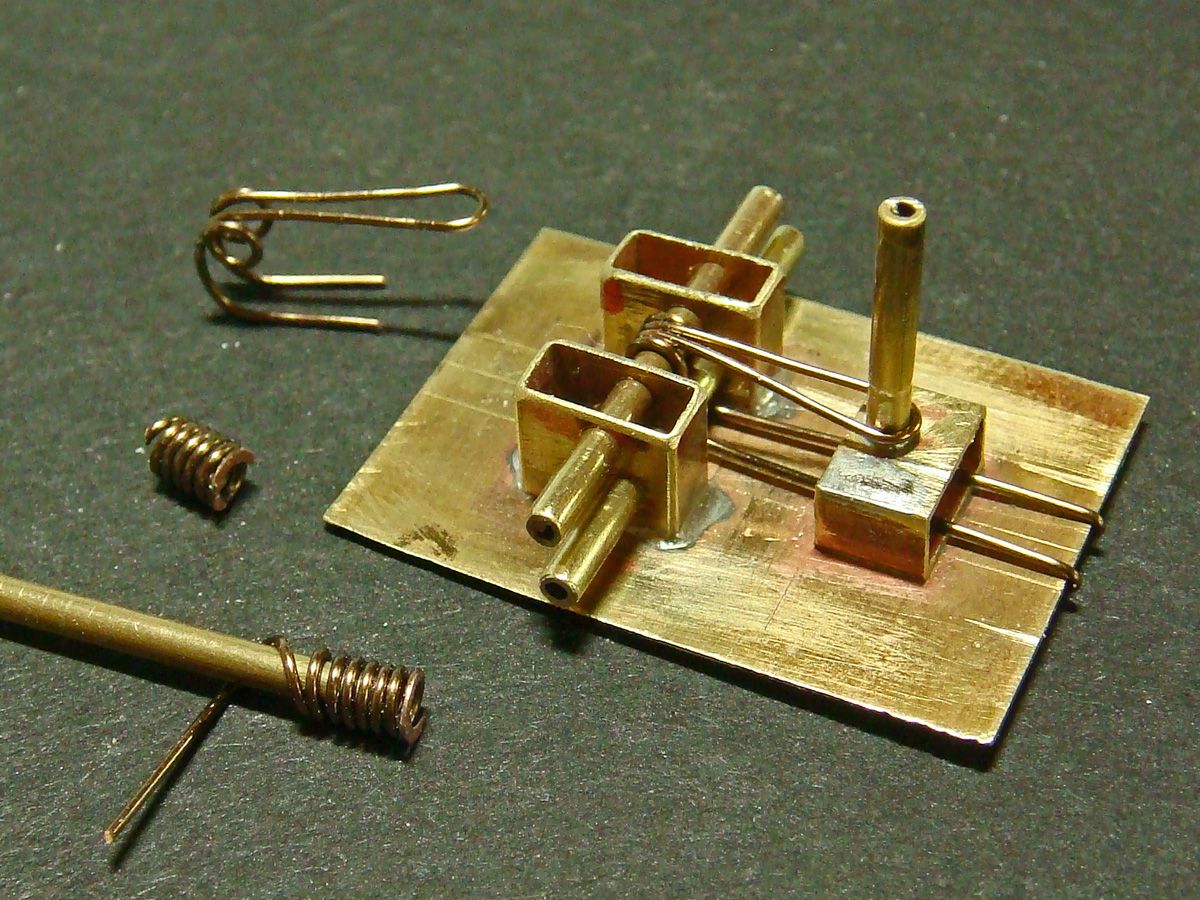

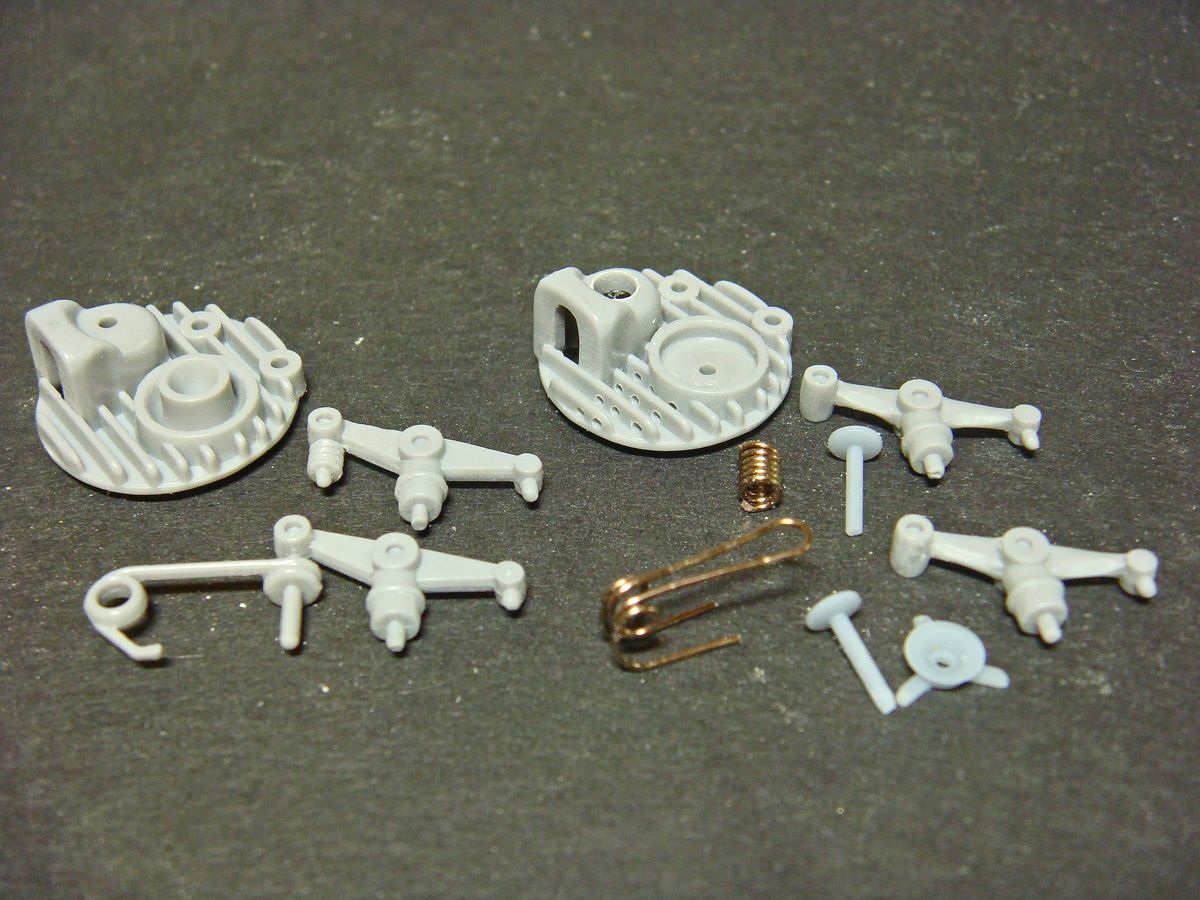

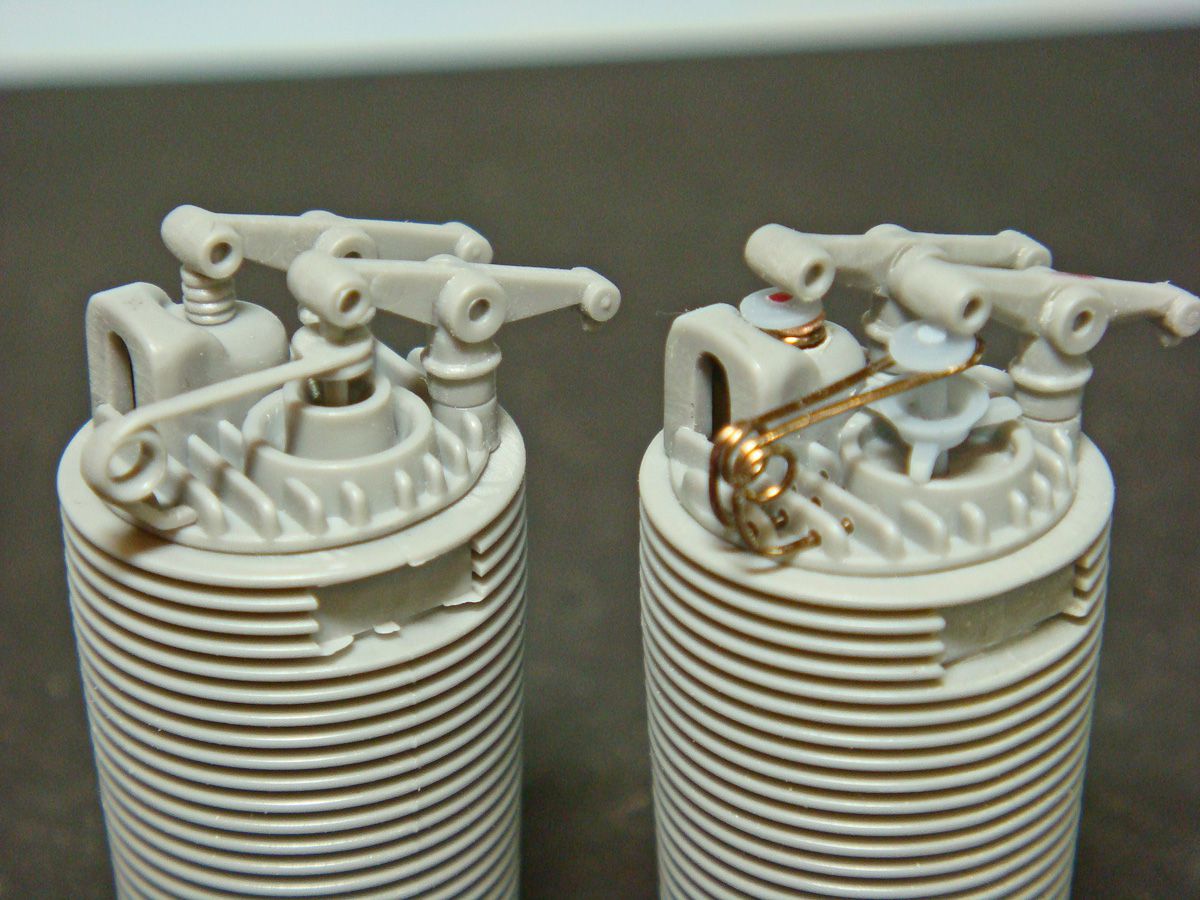

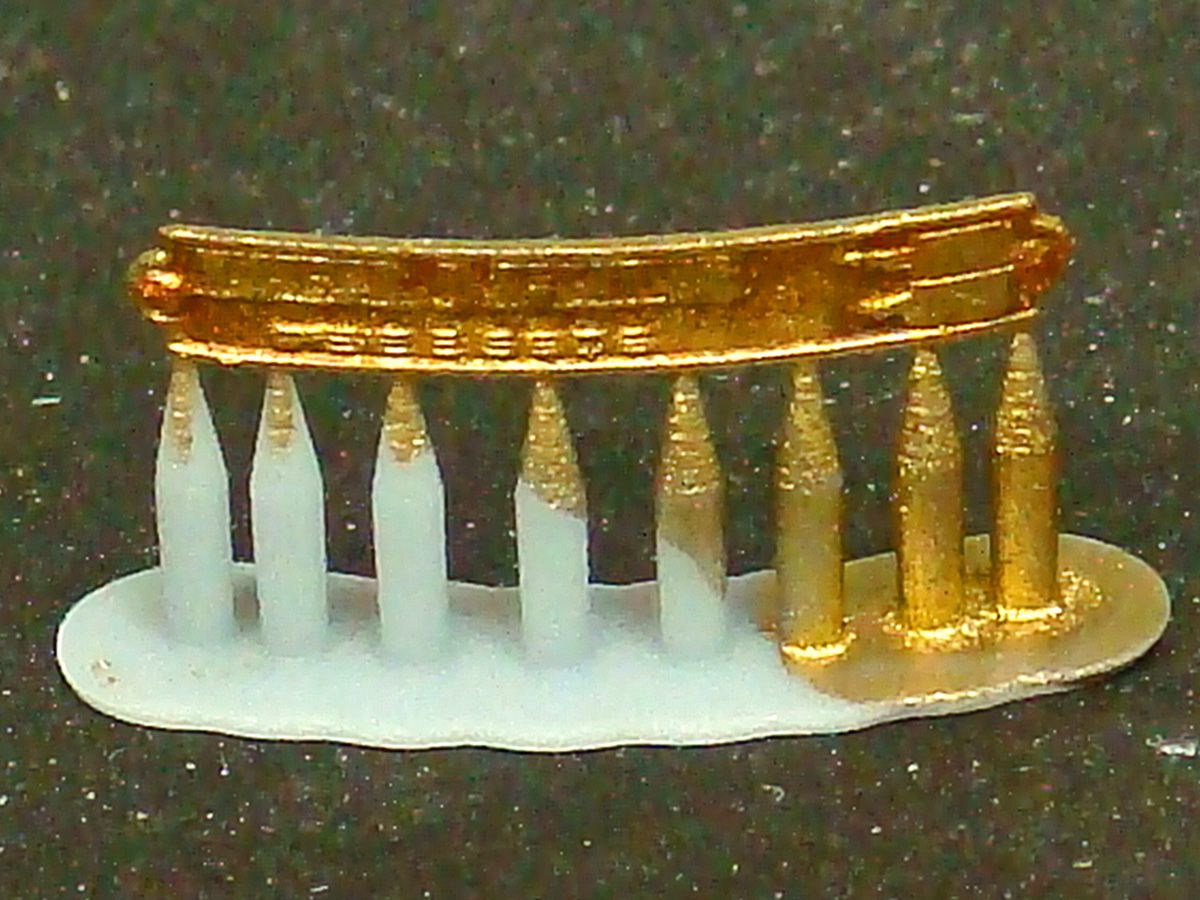

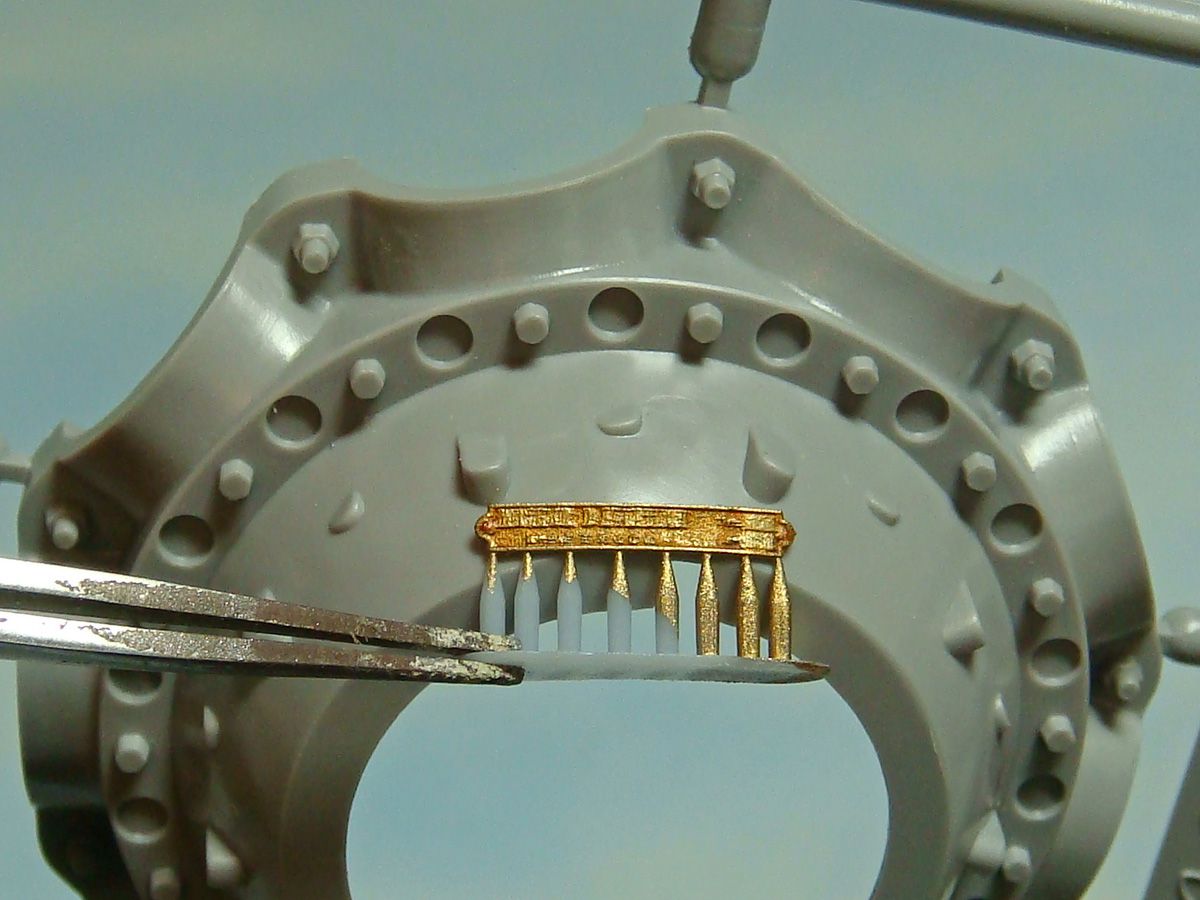

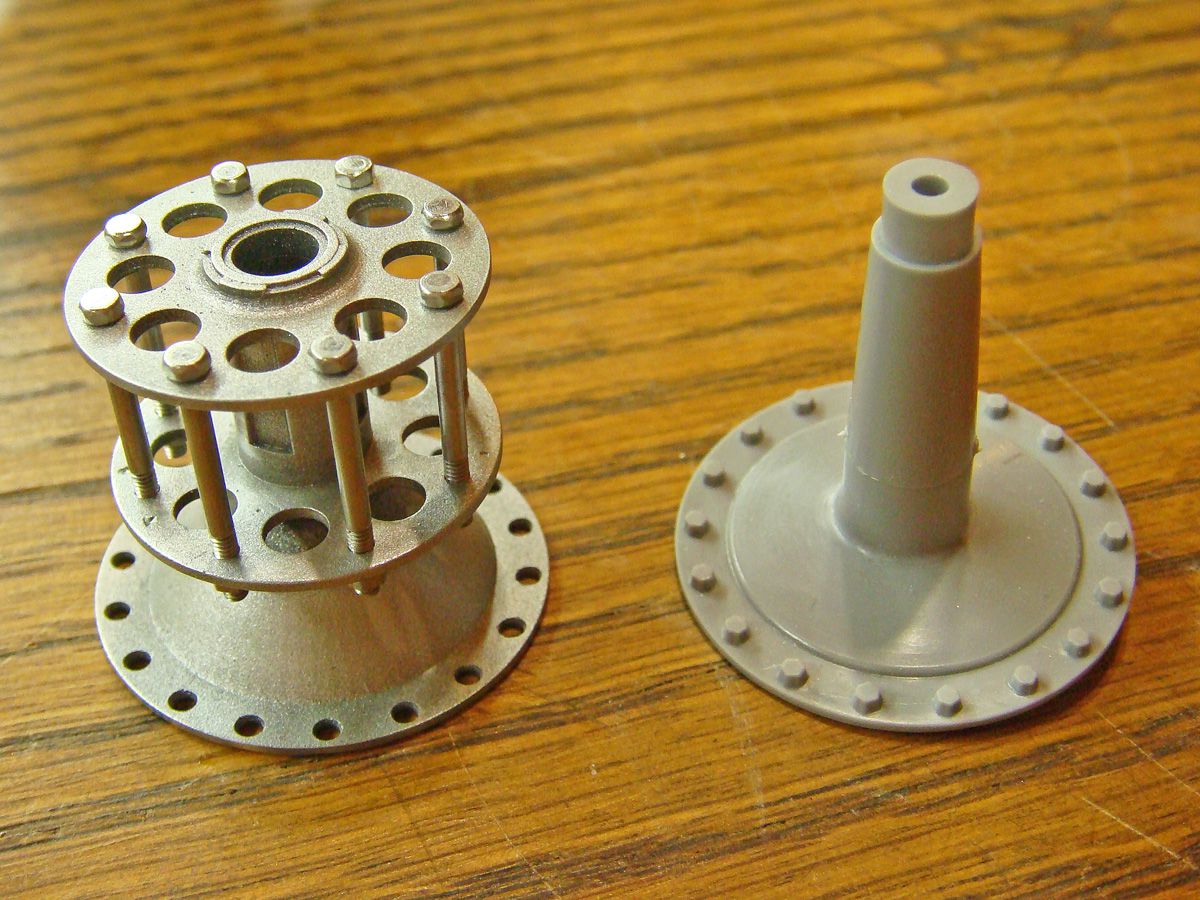

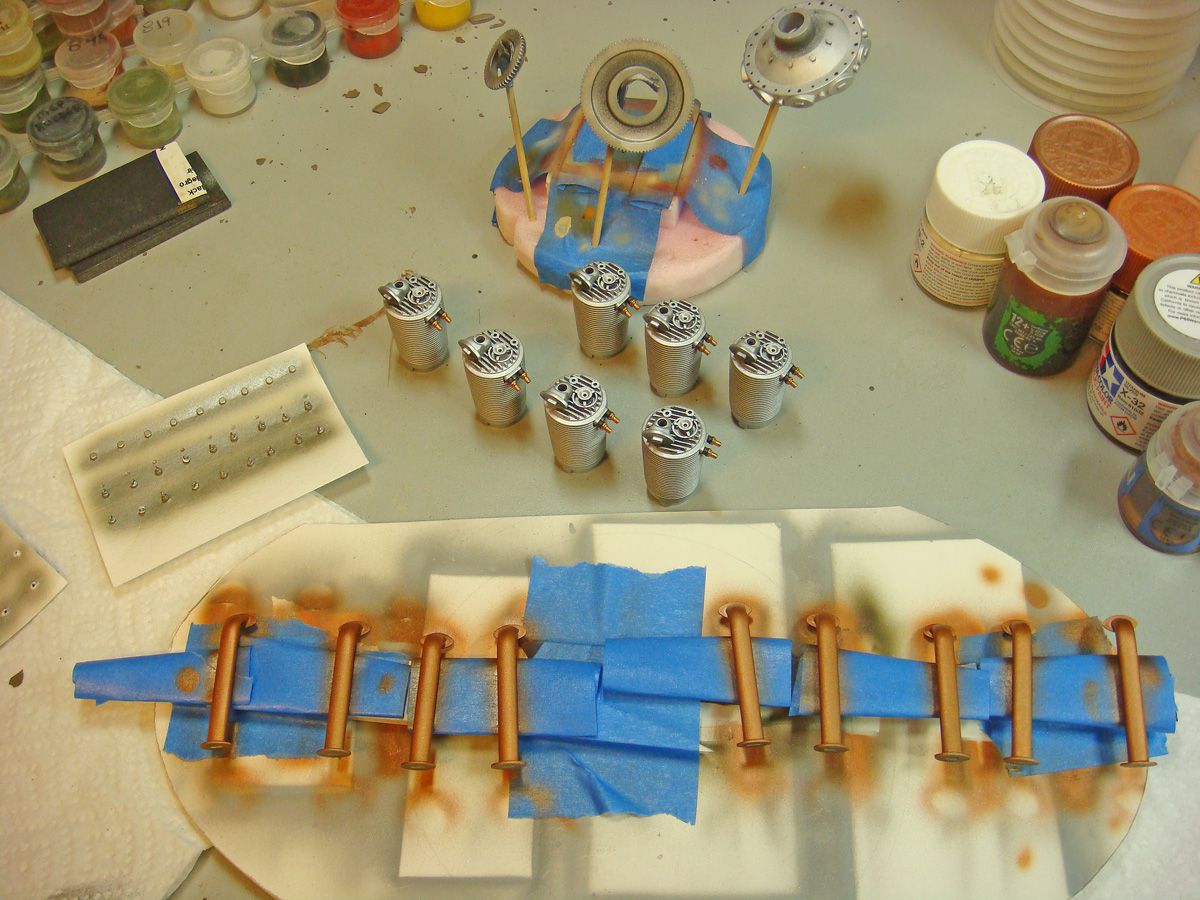

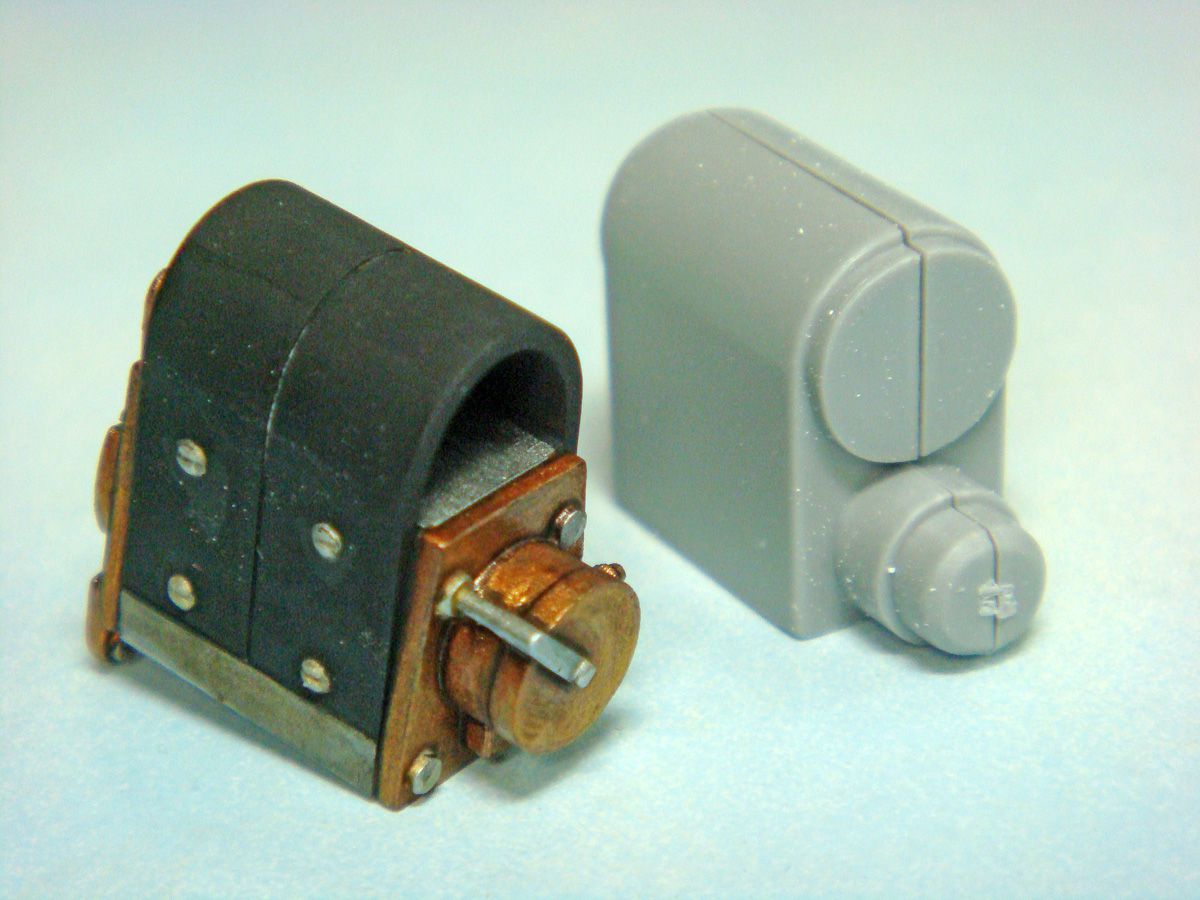

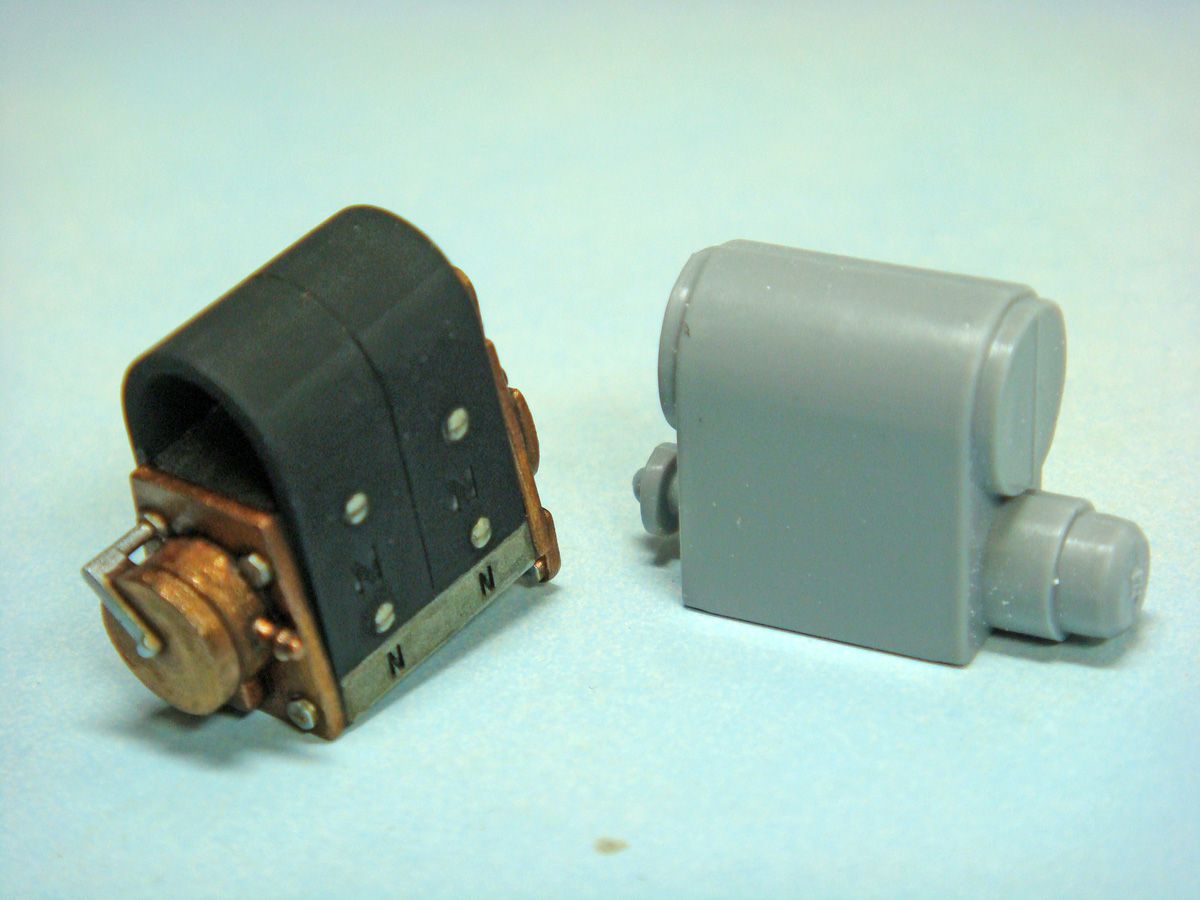

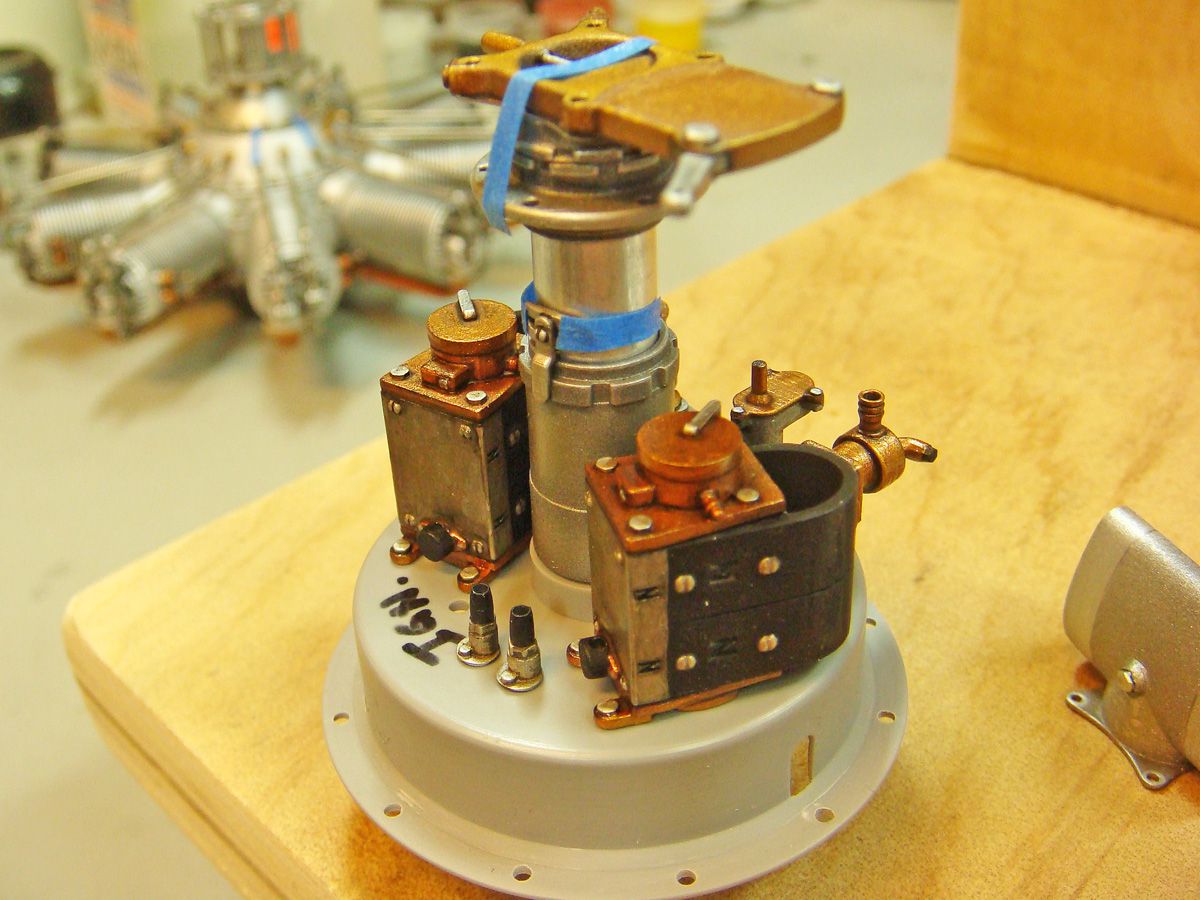

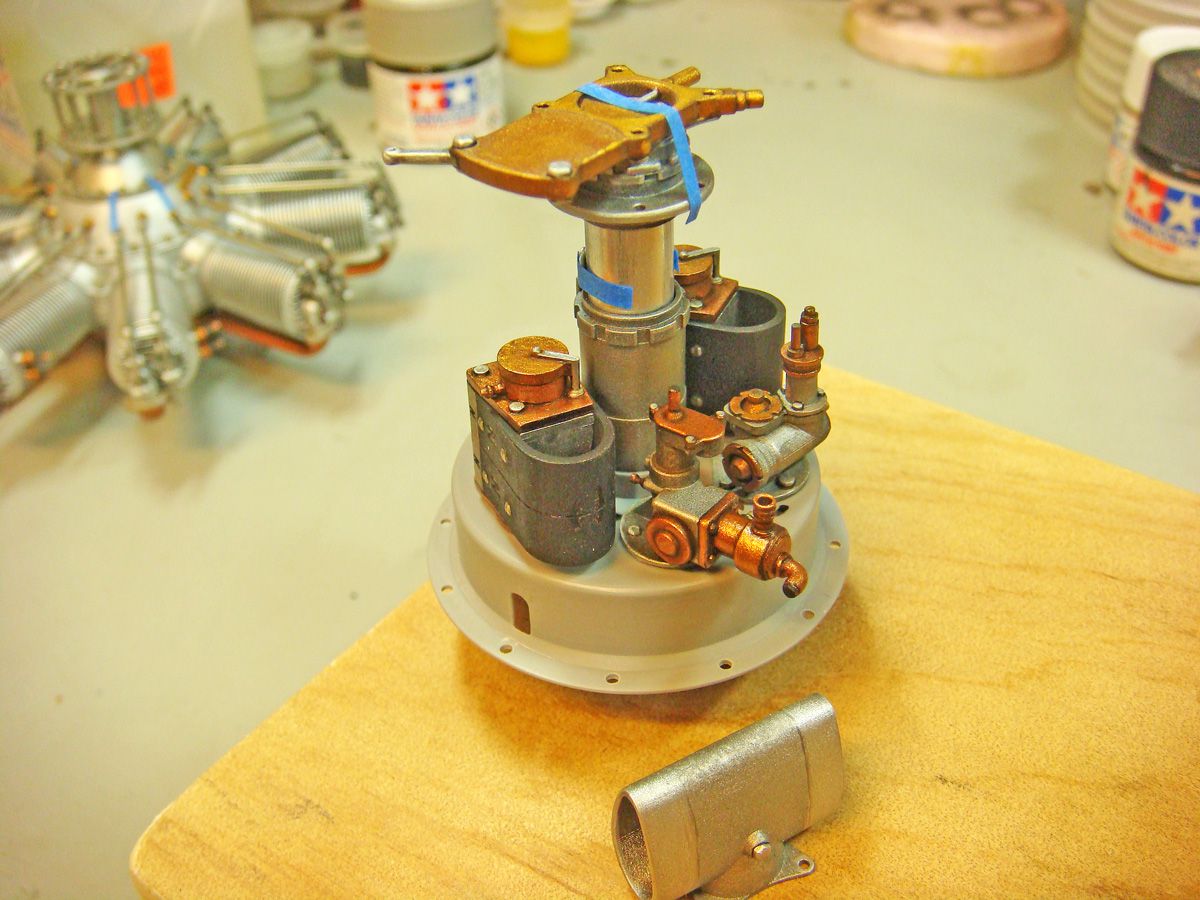

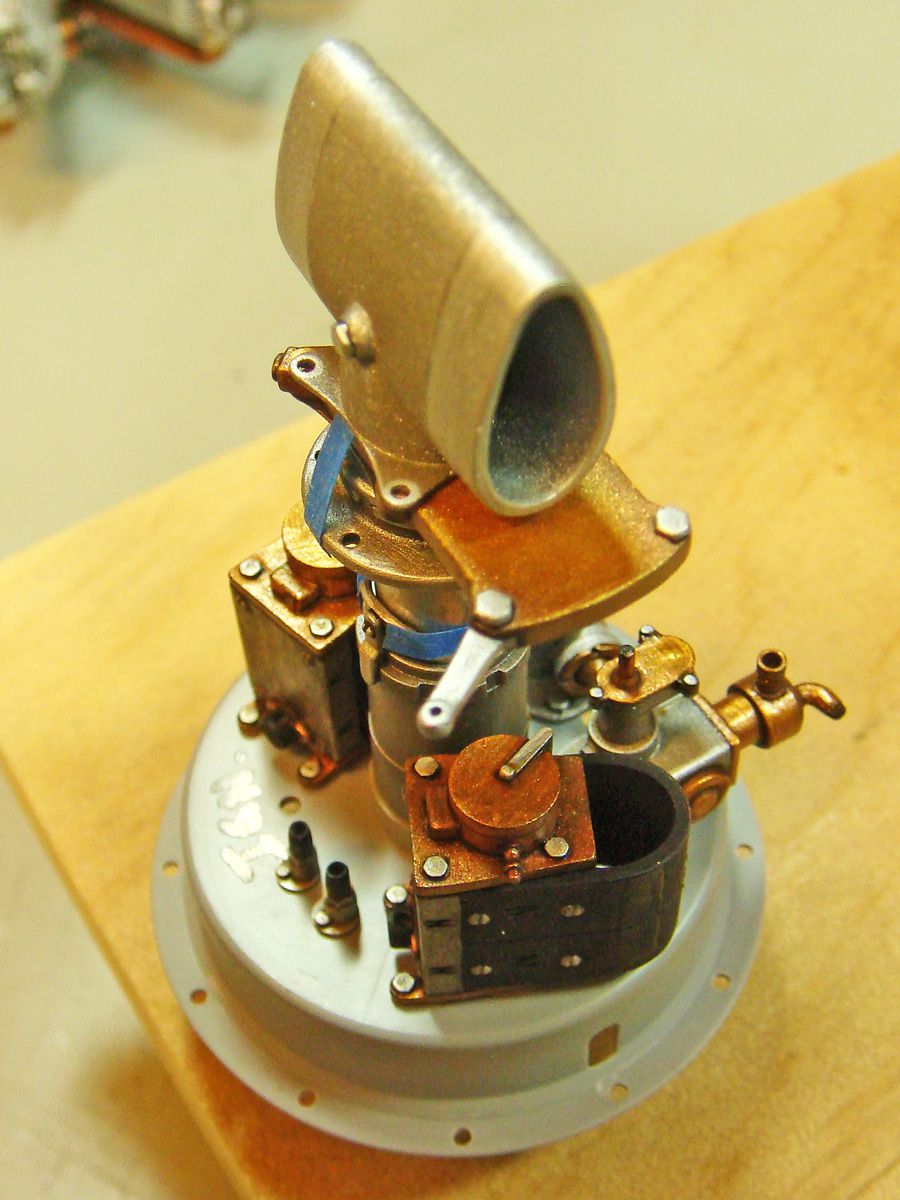

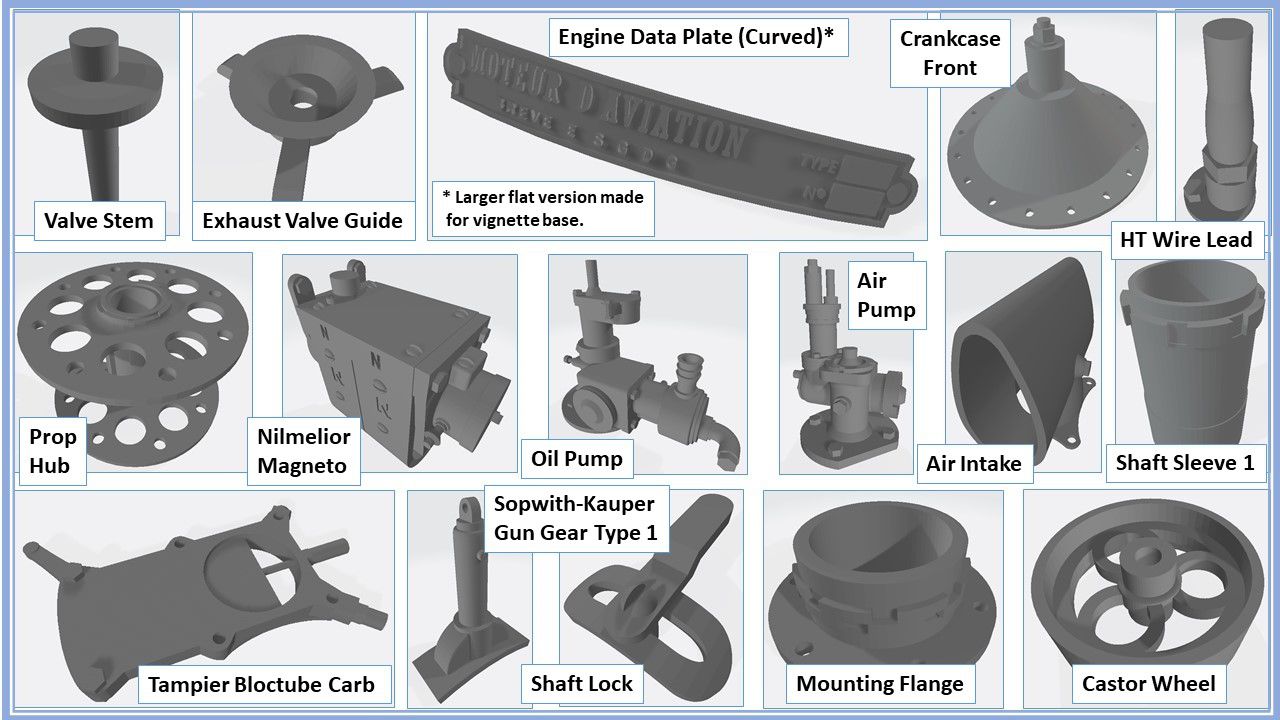

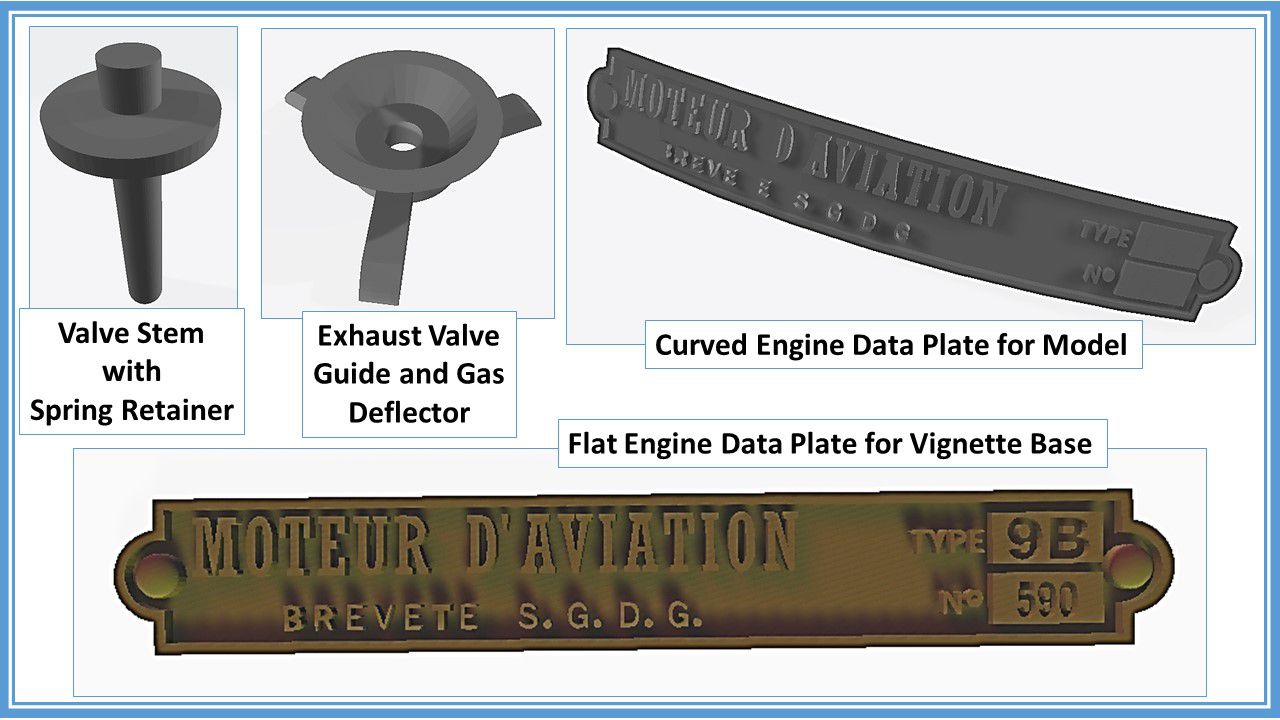

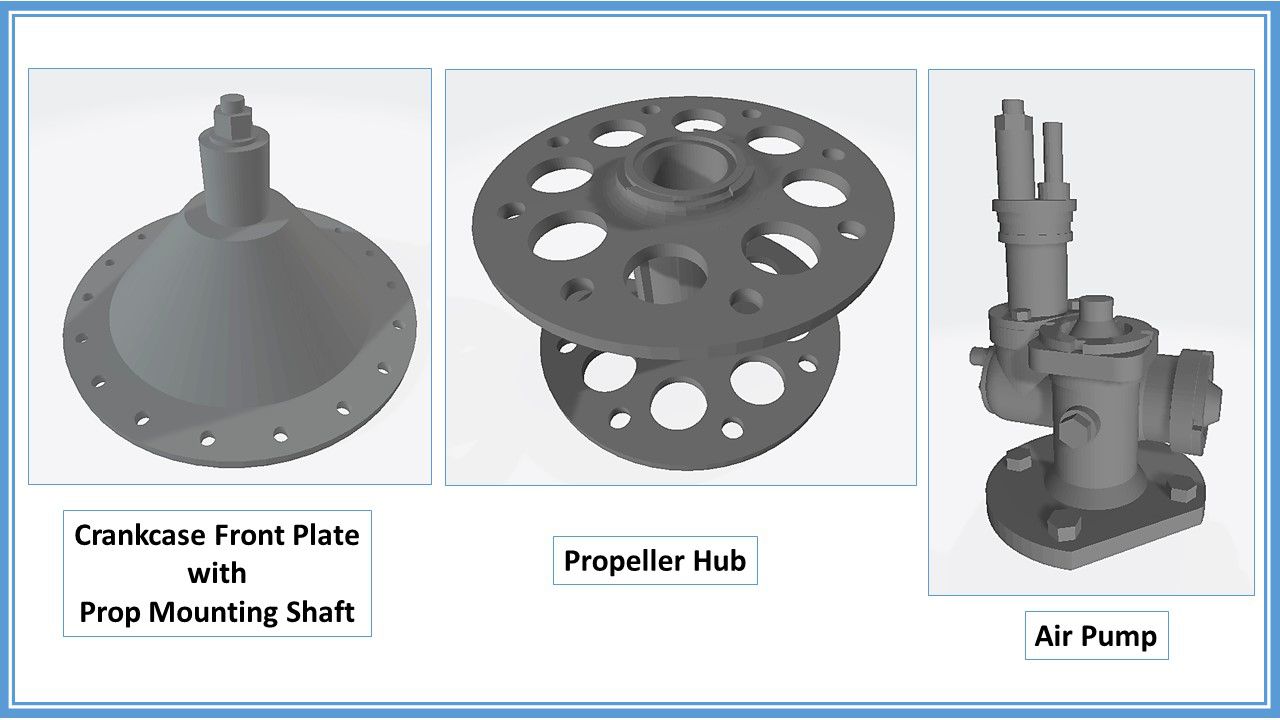

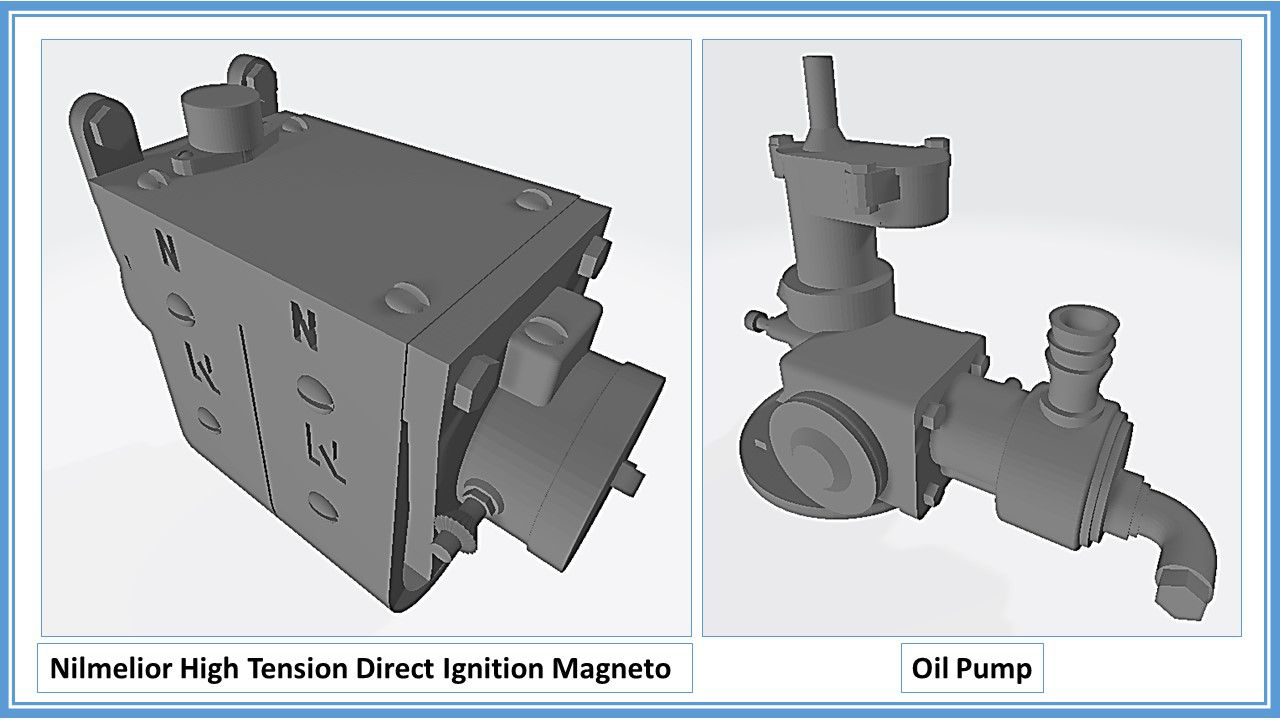

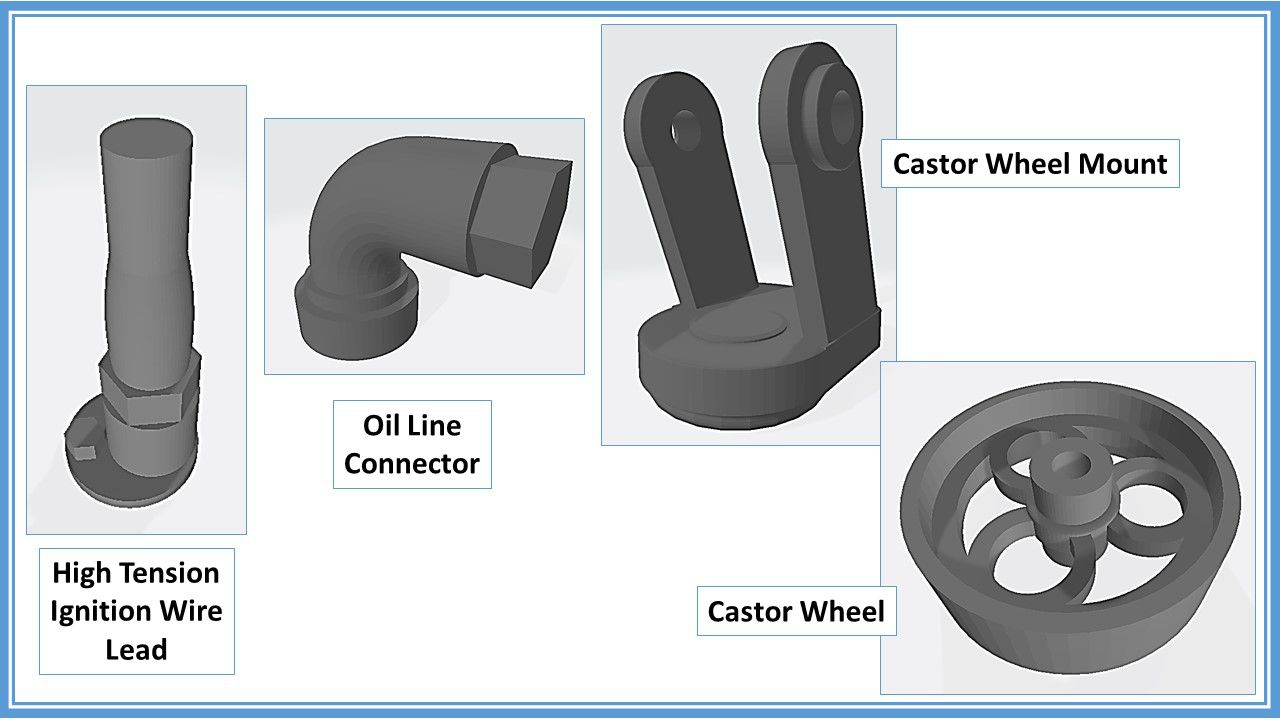

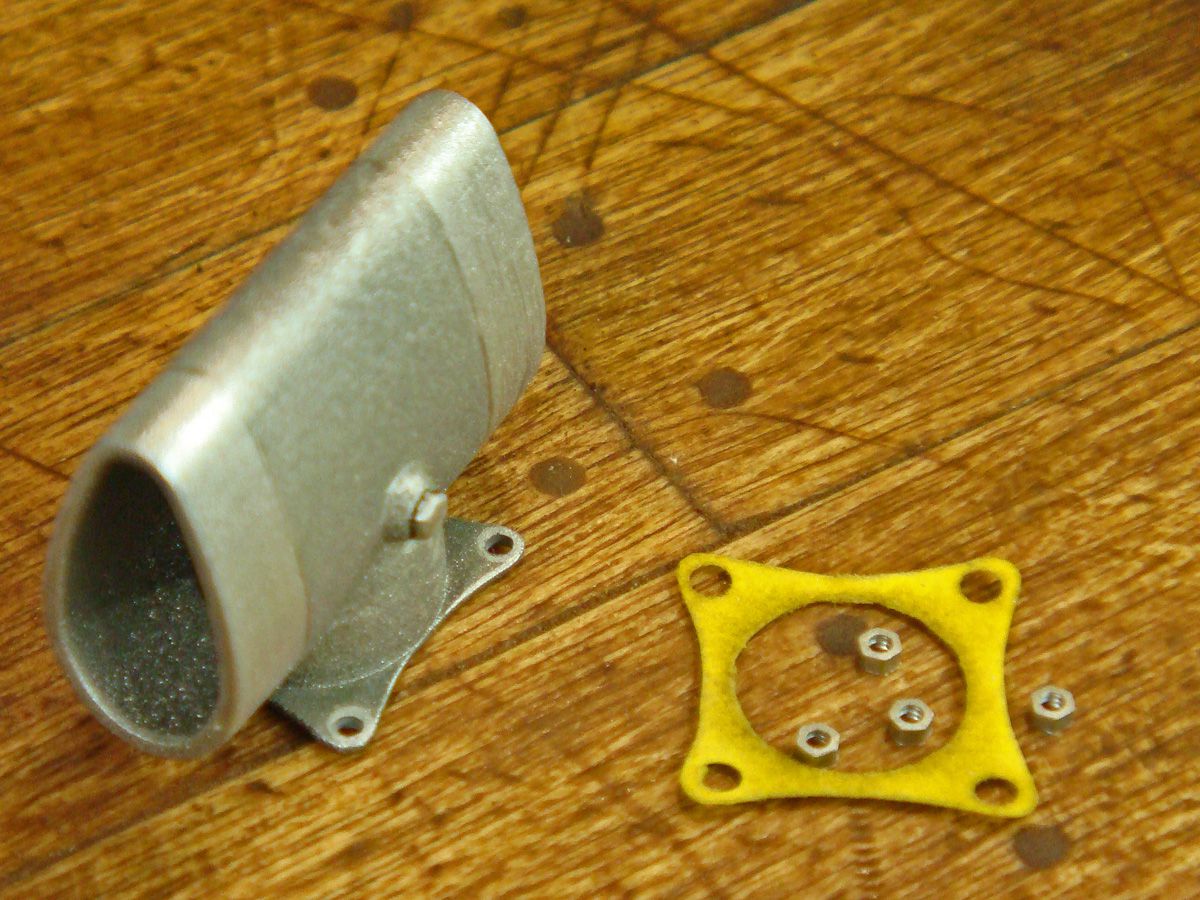

Based on my research, I determined a number of areas that could be improved. In addition to employing traditional scratch-building techniques and materials, I also used CAD to devise a number of new and replacement parts which I then printed using a resin-type SLA table top 3D printer. Because of the lack of actual plans and dimensioned drawings of the prototype engine, I had to “reverse engineer” the scale part dimensions while attempting to make them “proportional” to the areas depicted in my reference photos. Many of these CAD designs went through several evolutions of printing and test fitting before I was satisfied that they at least “looked” correct. I believe that the in-progress photos illustrate most of these parts.

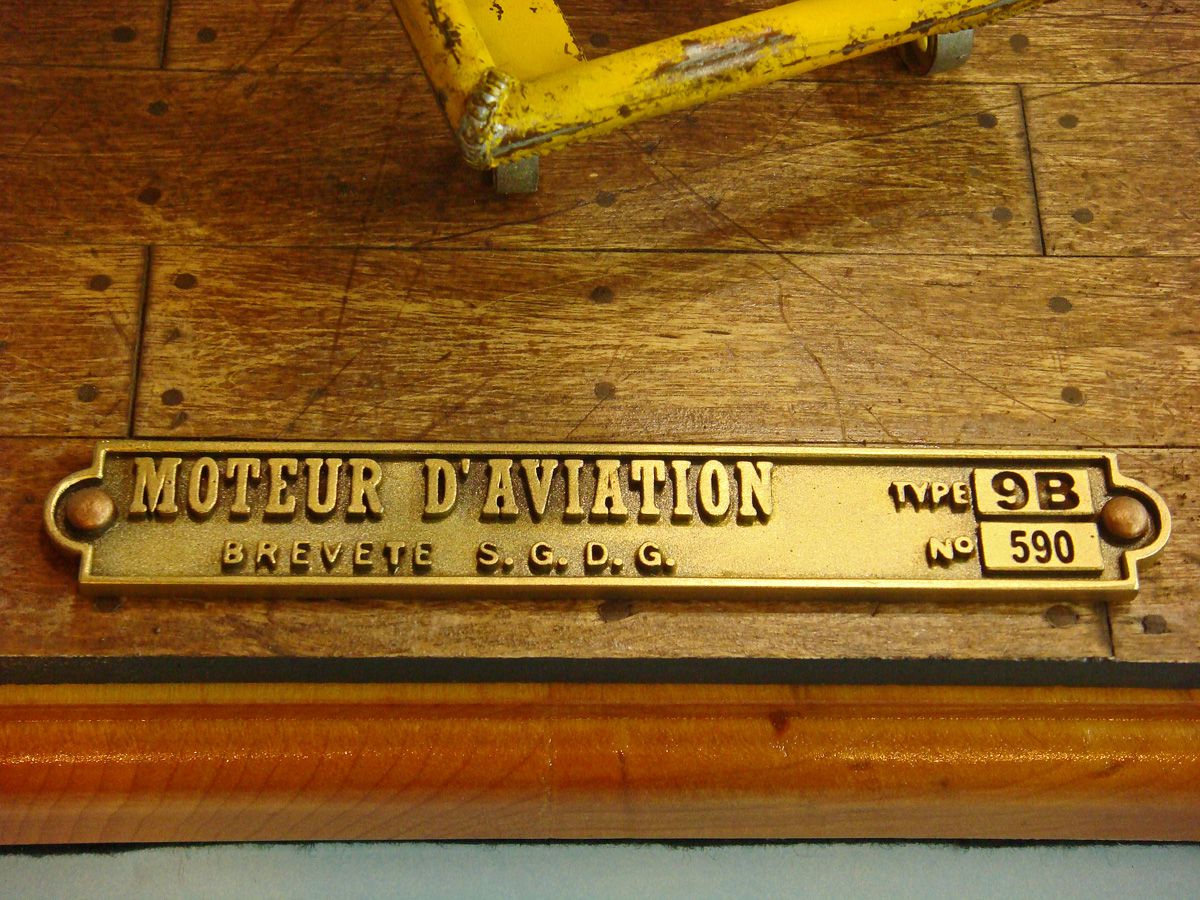

The 1/8 scale figure was an original CAD sculpt and 3D print done by my friend, Luis Hidalgo, who has a particular talent for such work. Luis based the figure on a number of period photos of French factory workers in order to get the clothing details correct. After assembly and preparation, I painted the figure by undercoating it in acrylics and then doing the actual painting using artist oils. The engine stand was scratch-built from styrene stock with two-part epoxy putty for the weld beads and more 3D printed parts for the castor wheels. The tools and tool box were also 3D printed designs. The display base was “planked” to replicate a wooden factory floor using wood veneer shelf edging with round toothpick “pegs.” The title plate was an enlarged version of the same 3D printed engine data plate made for the actual model.

You must be logged in to post a comment.