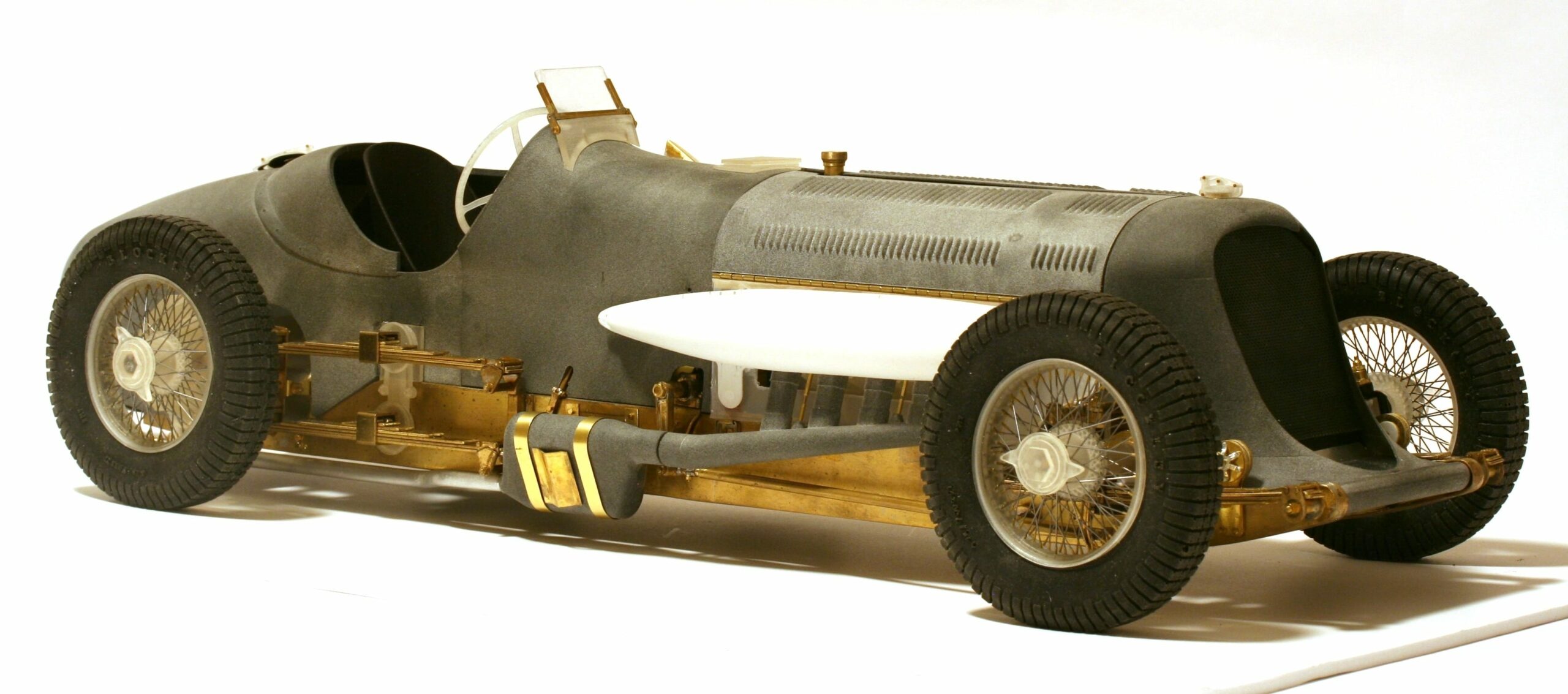

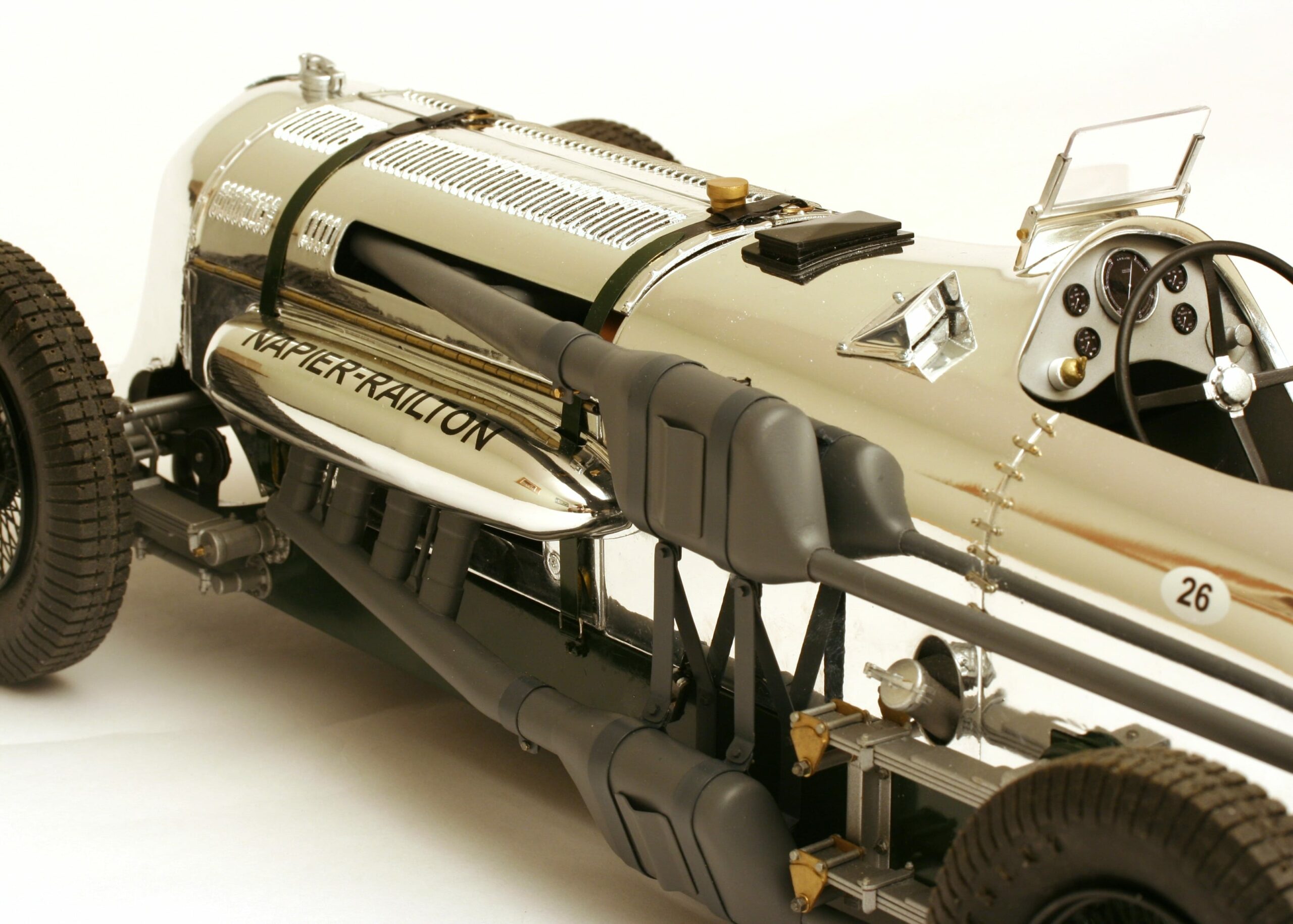

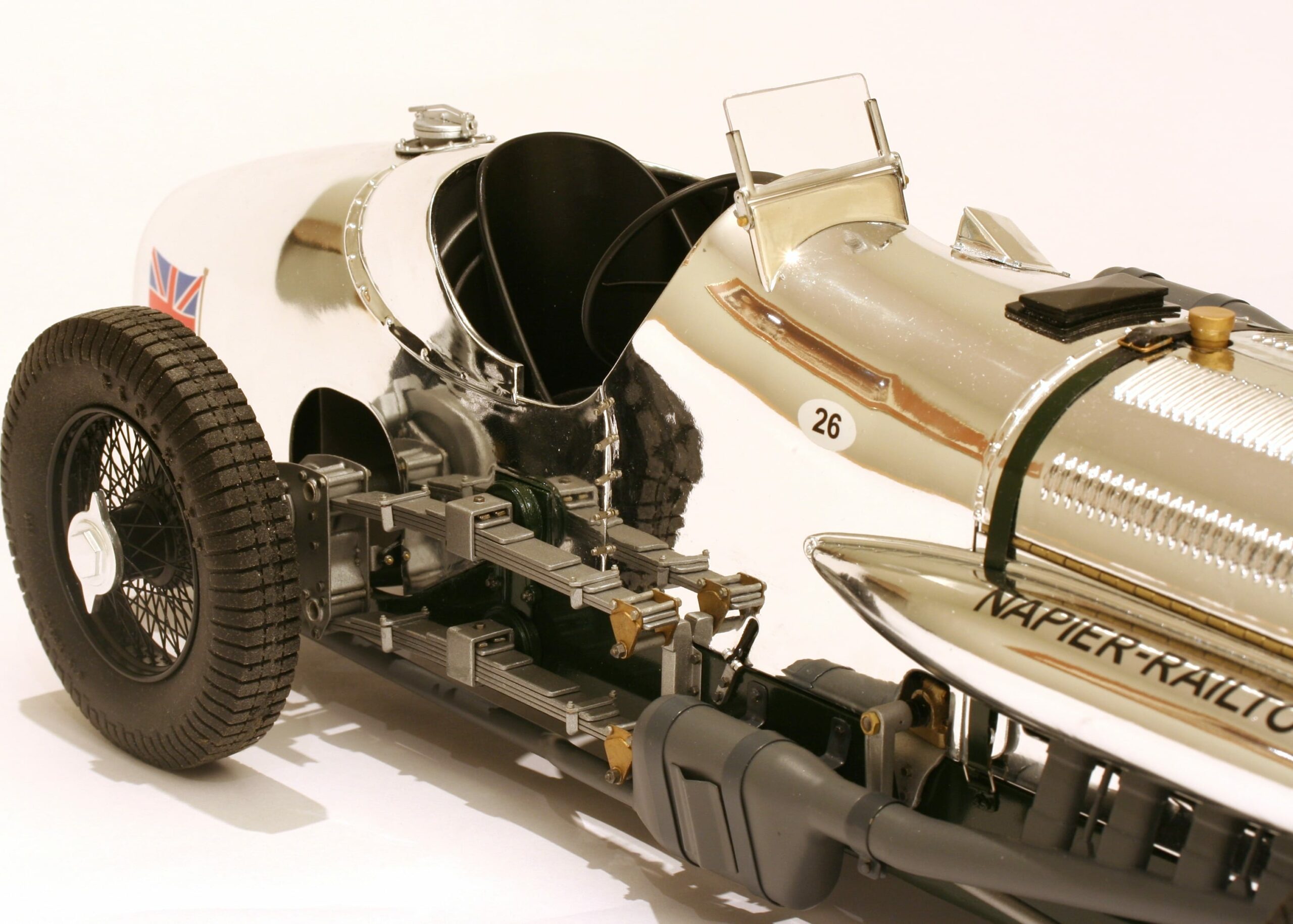

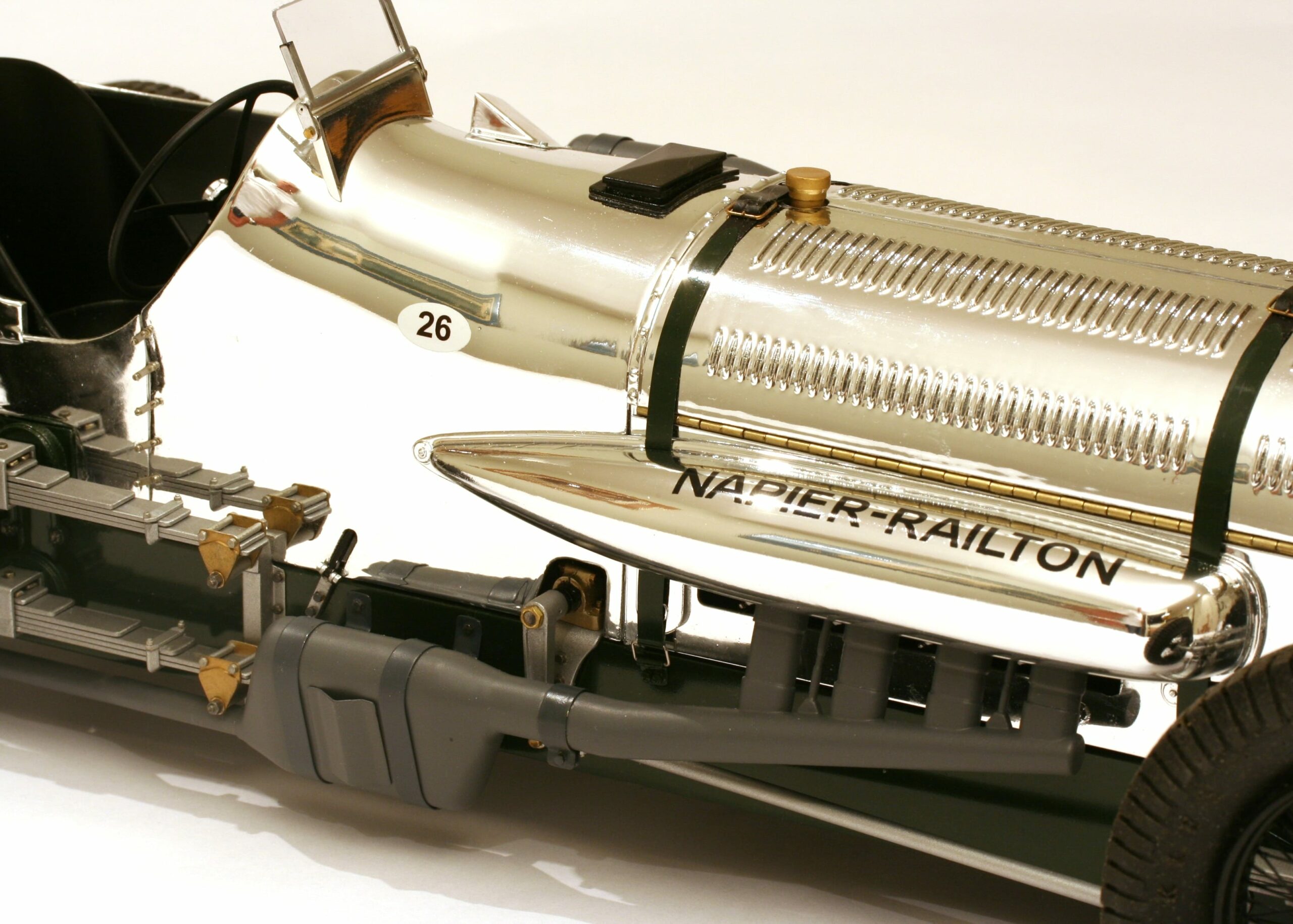

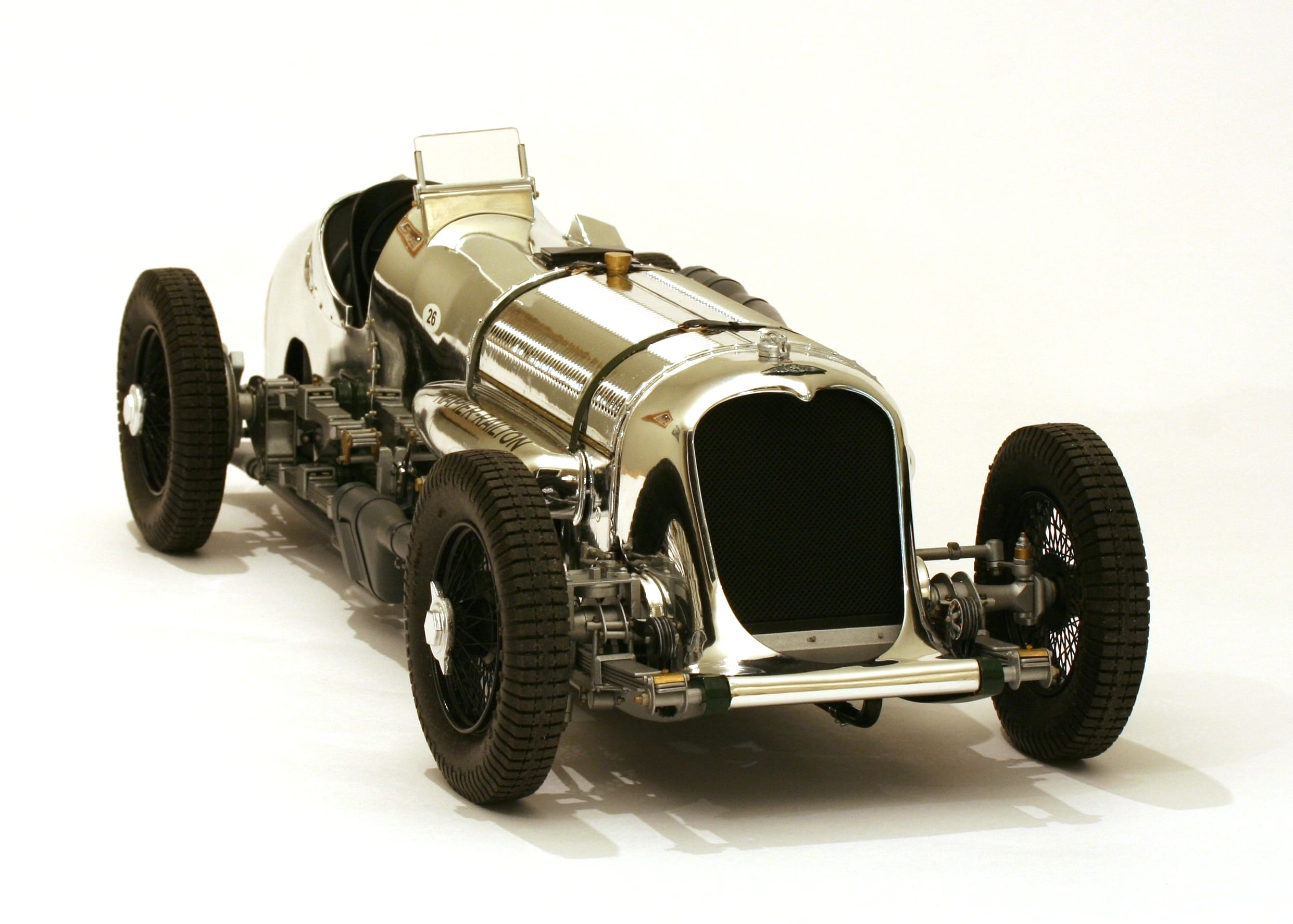

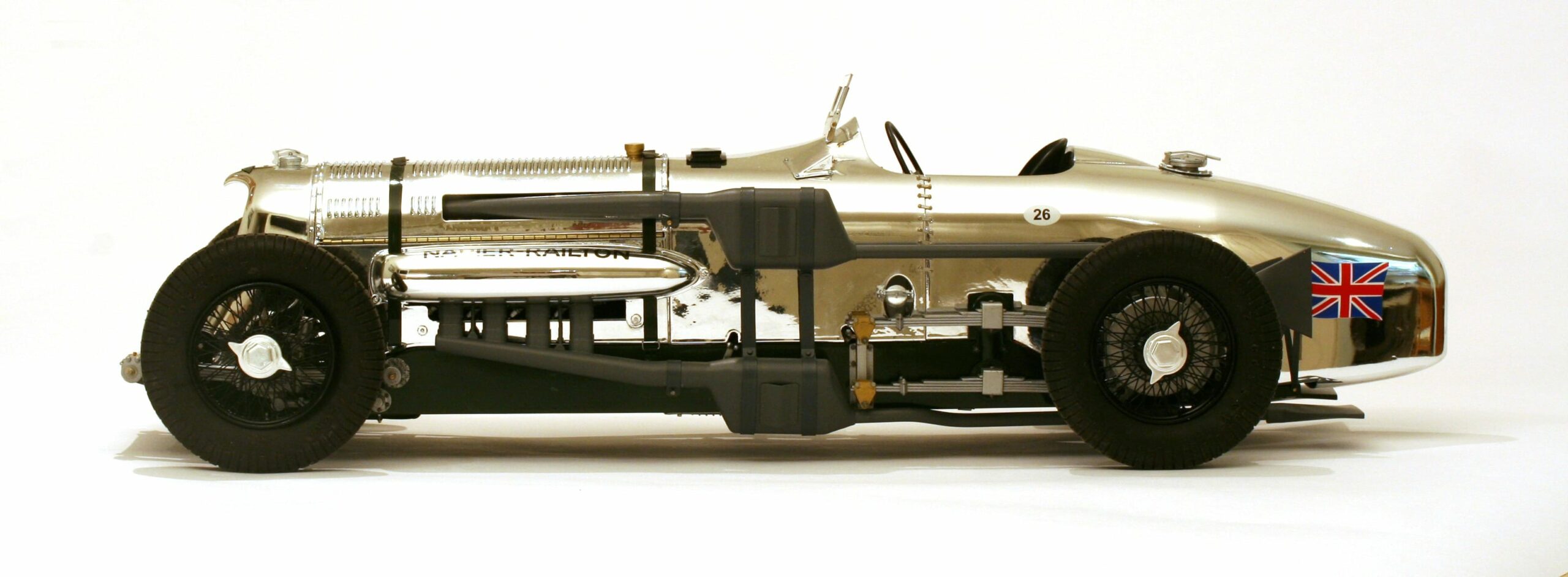

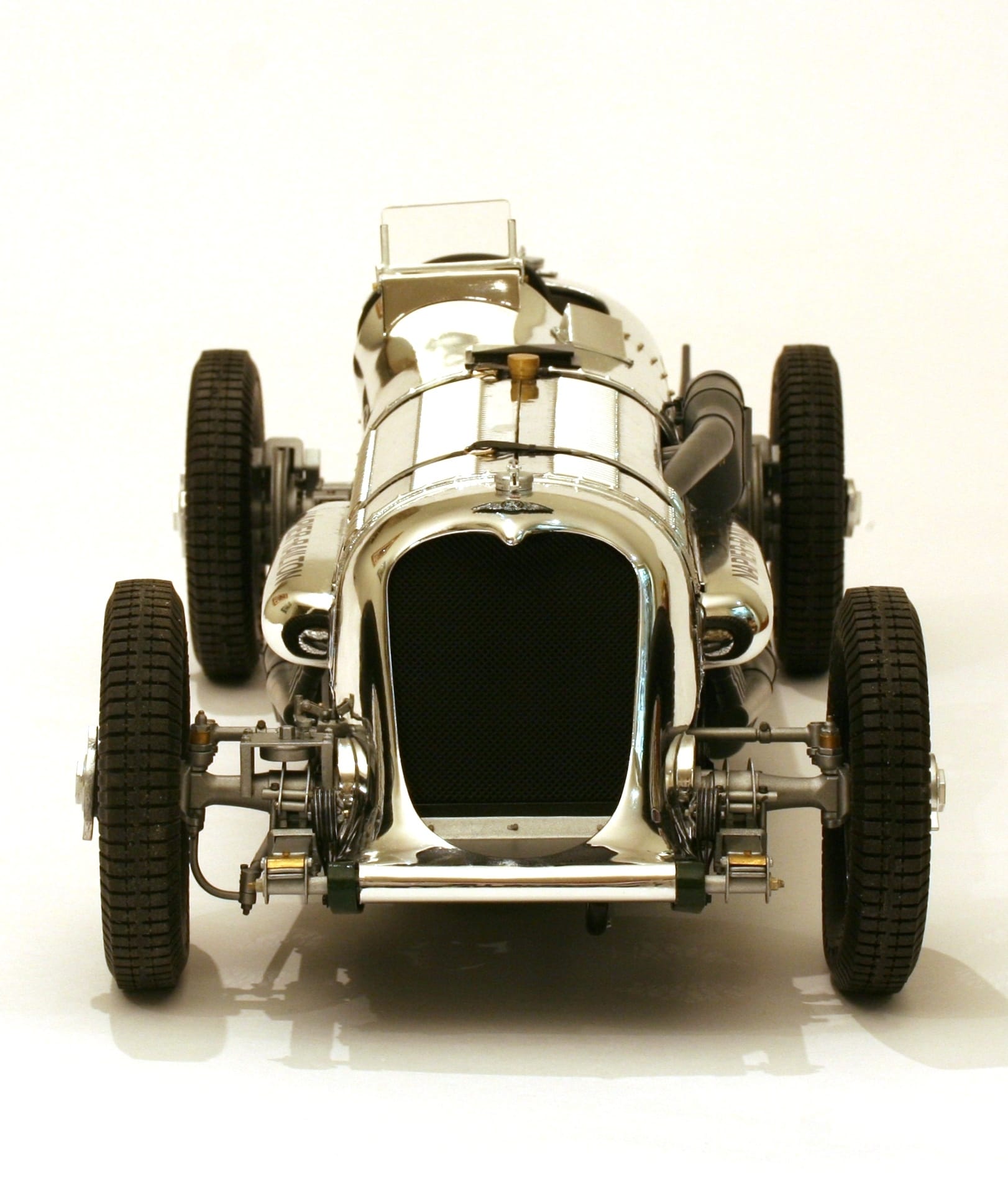

John Haddock's

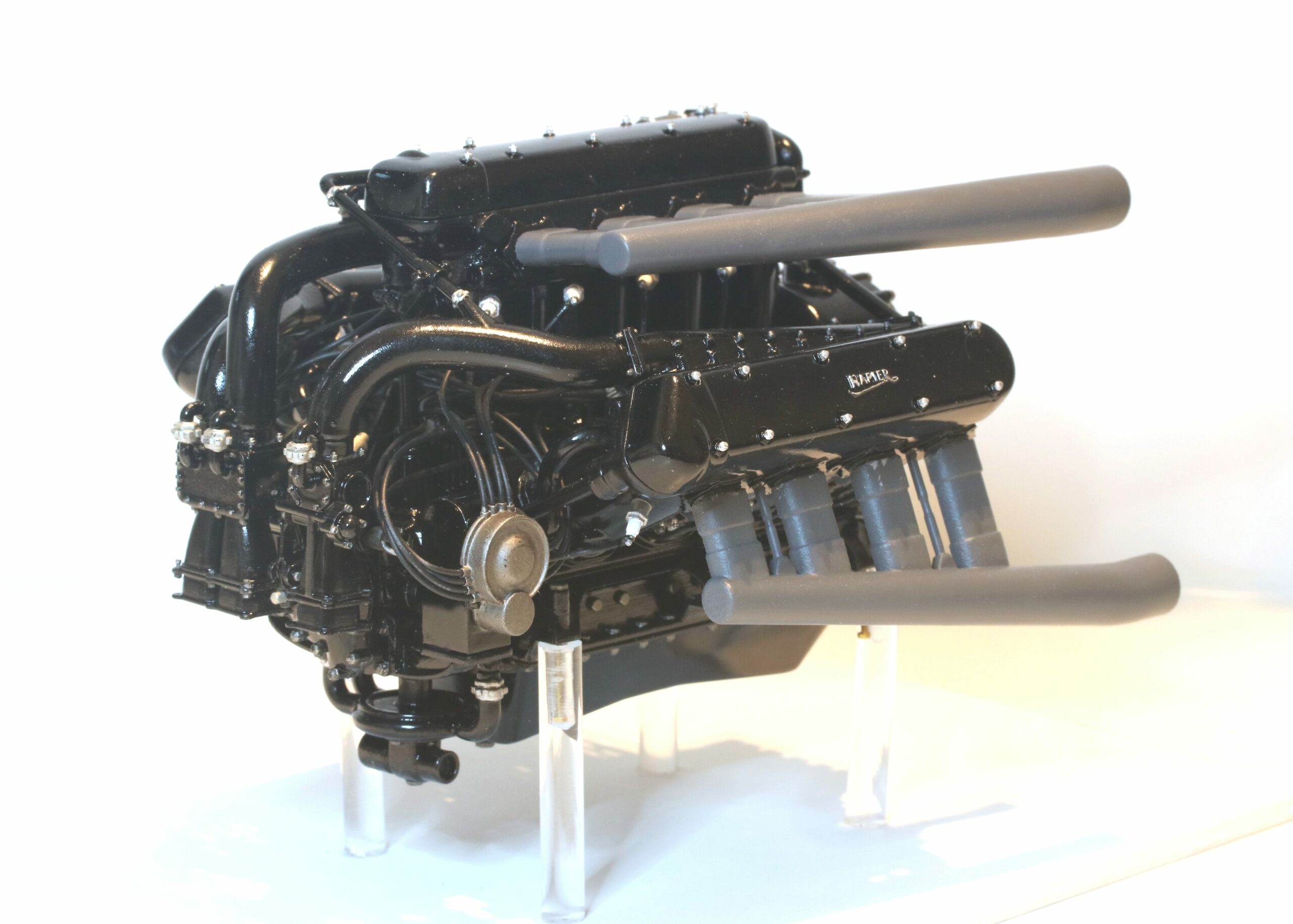

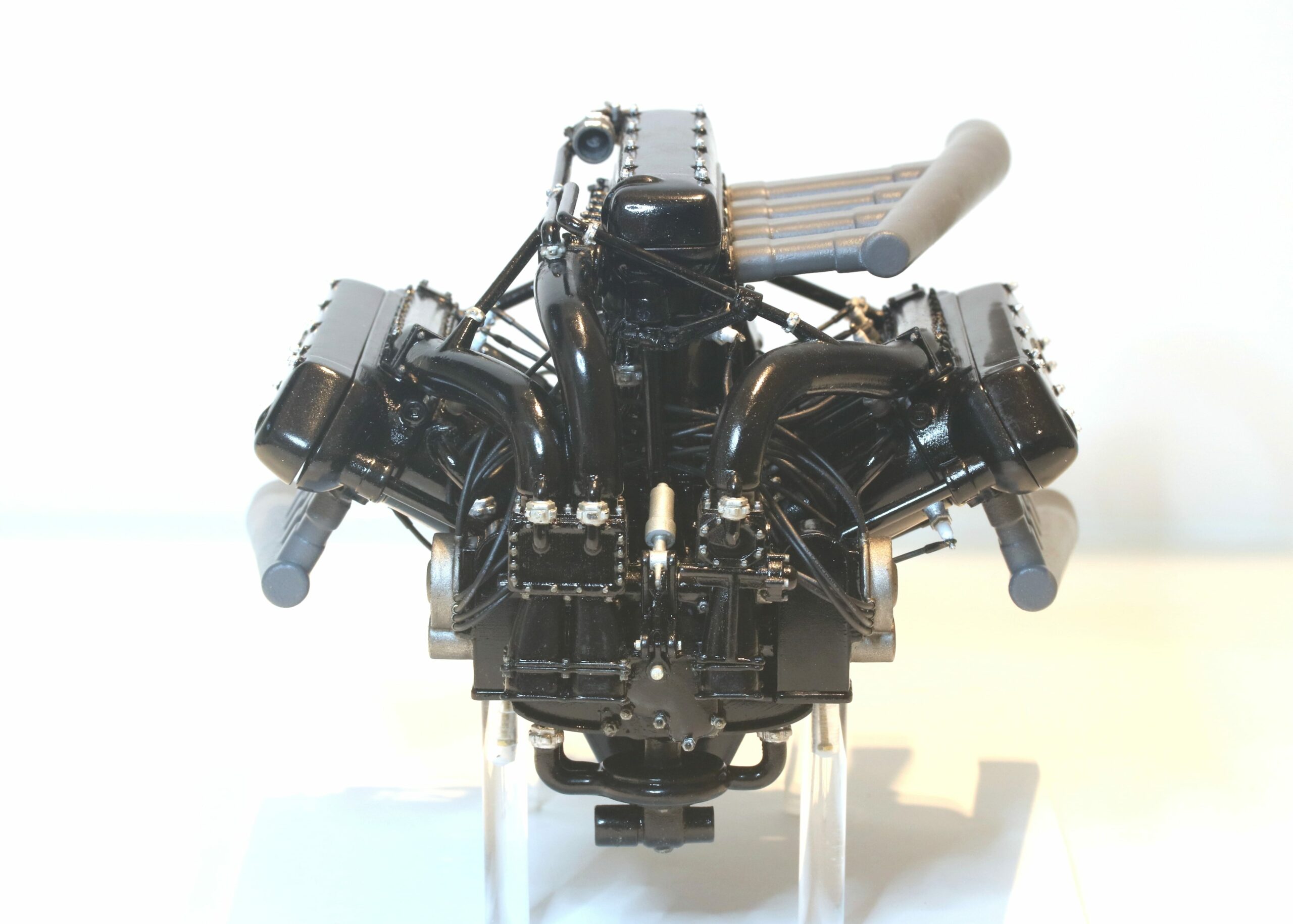

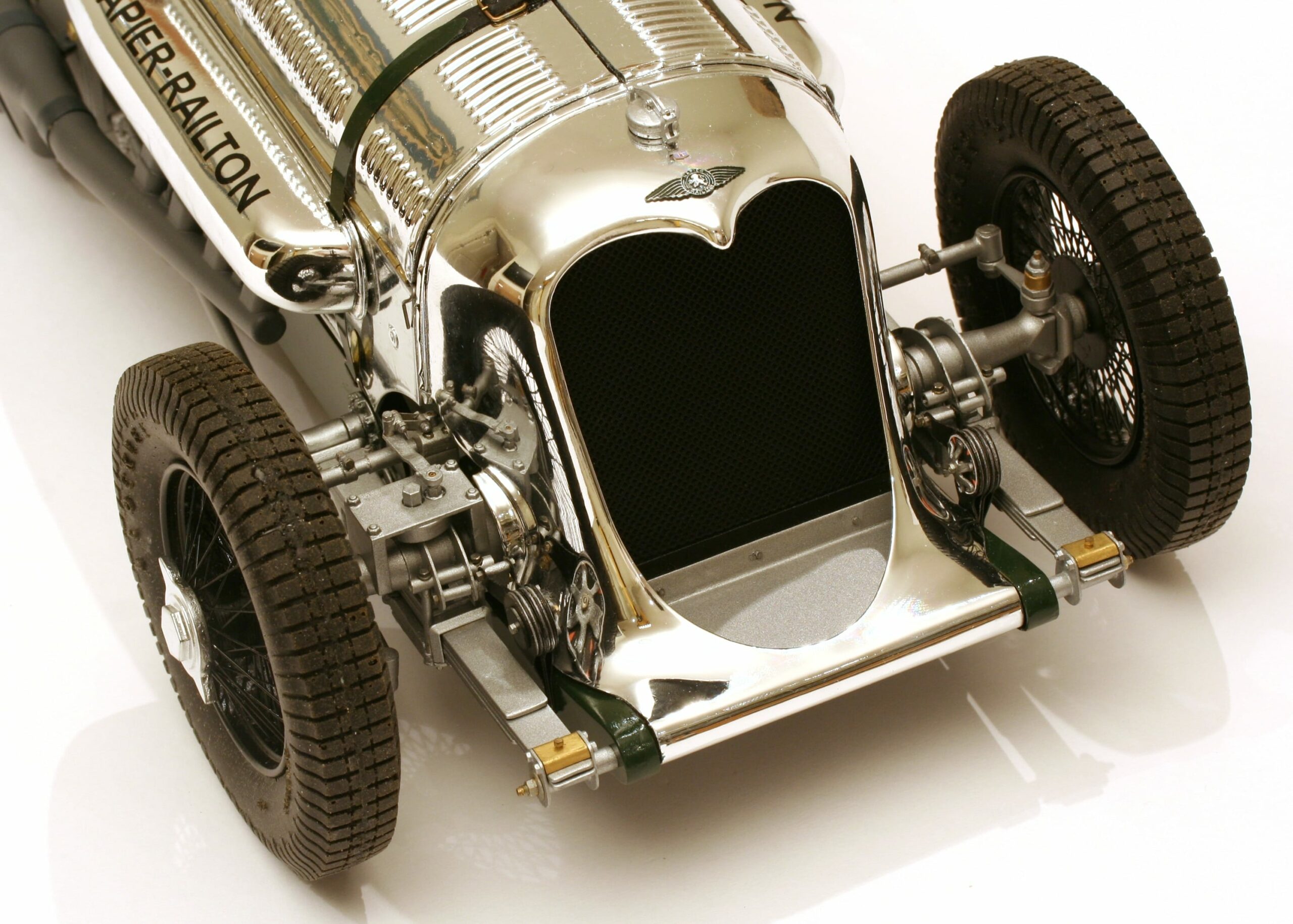

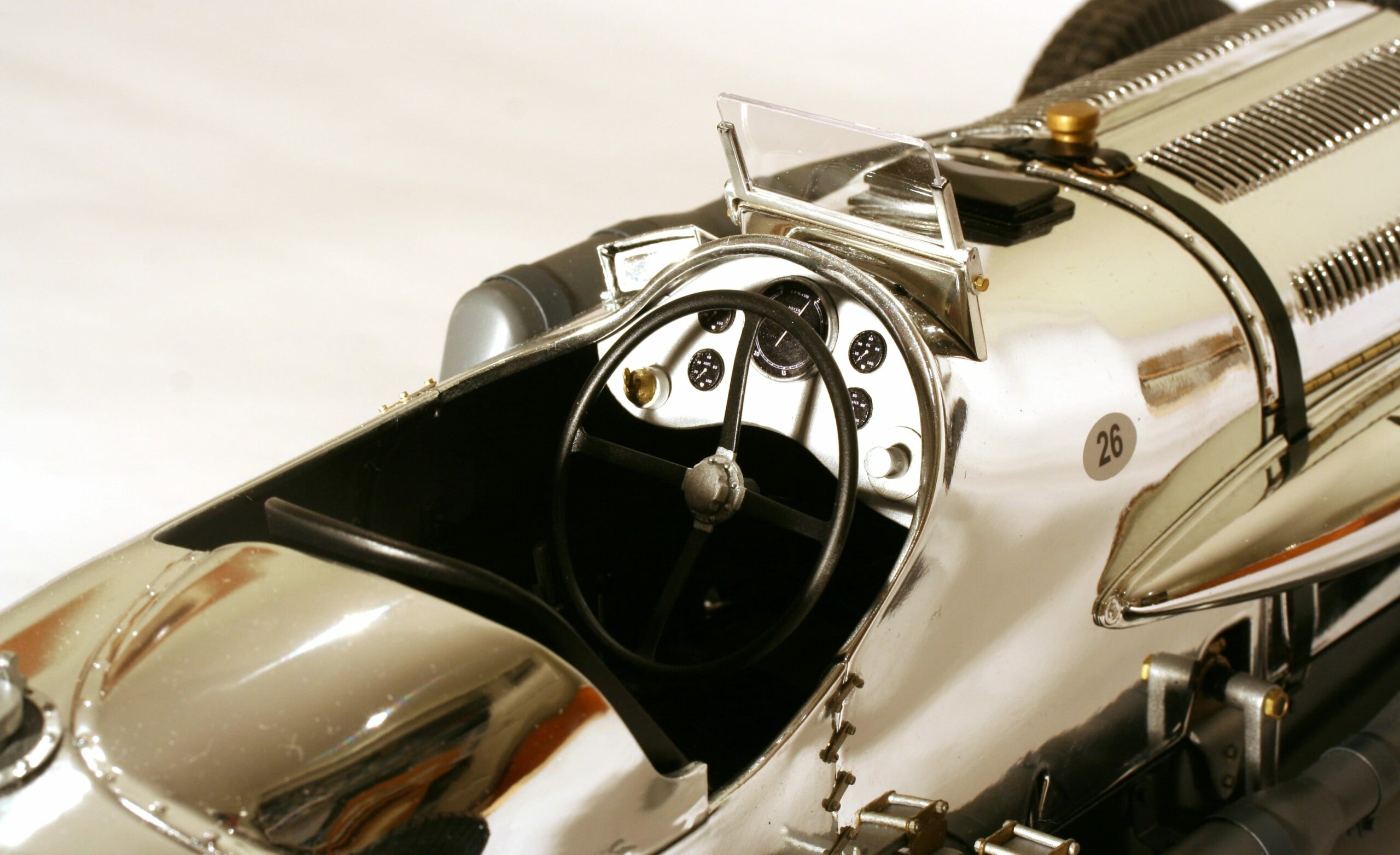

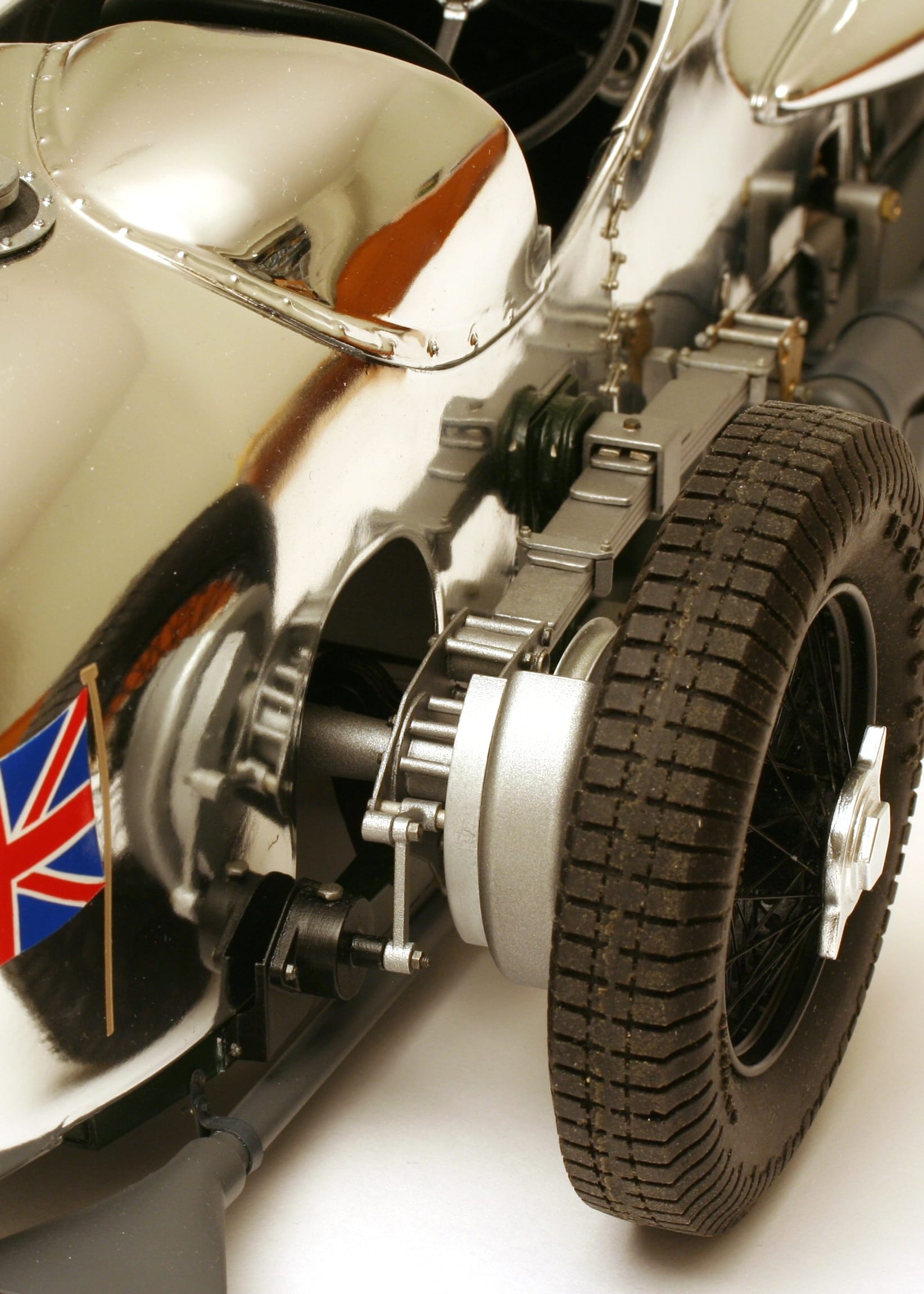

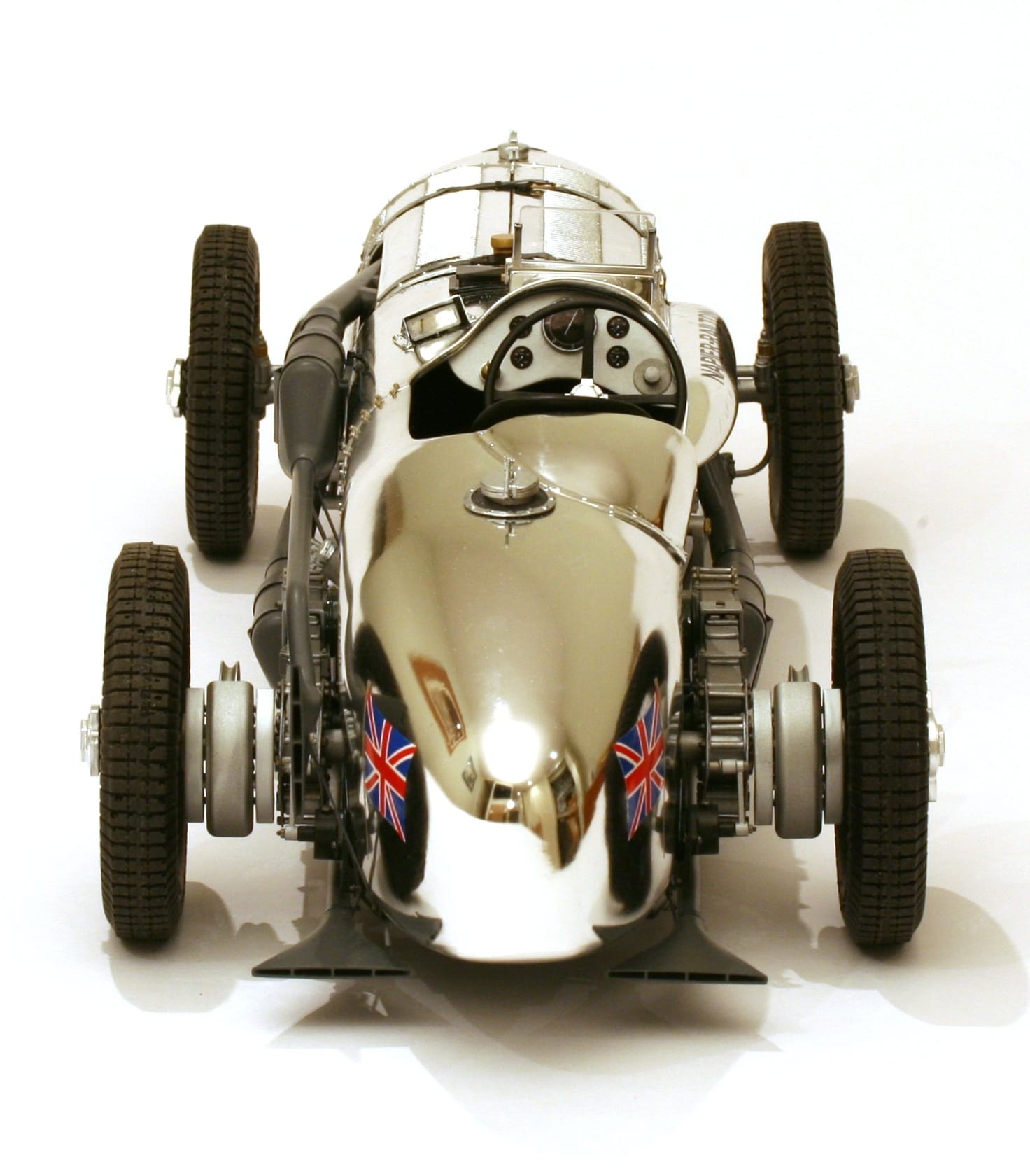

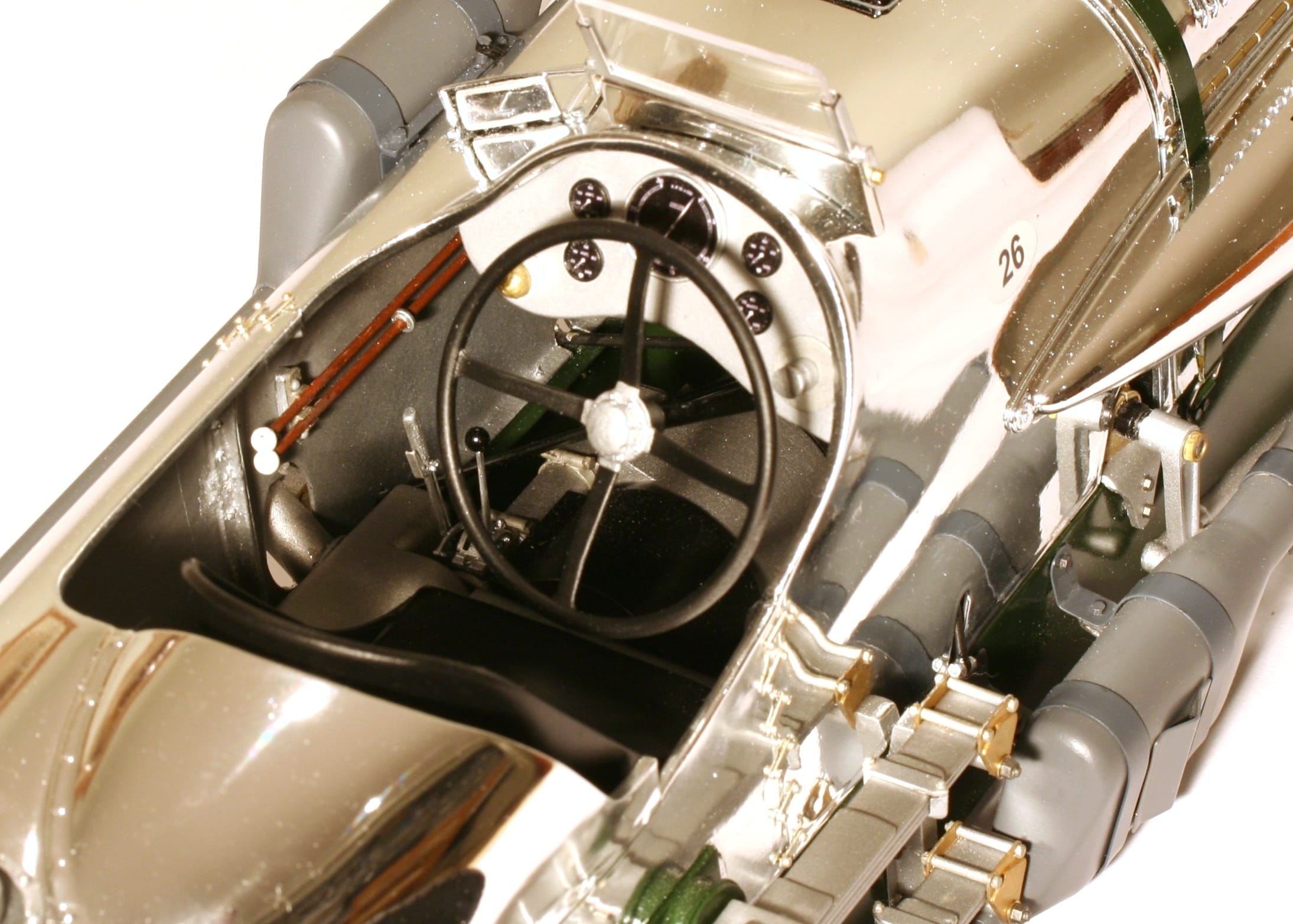

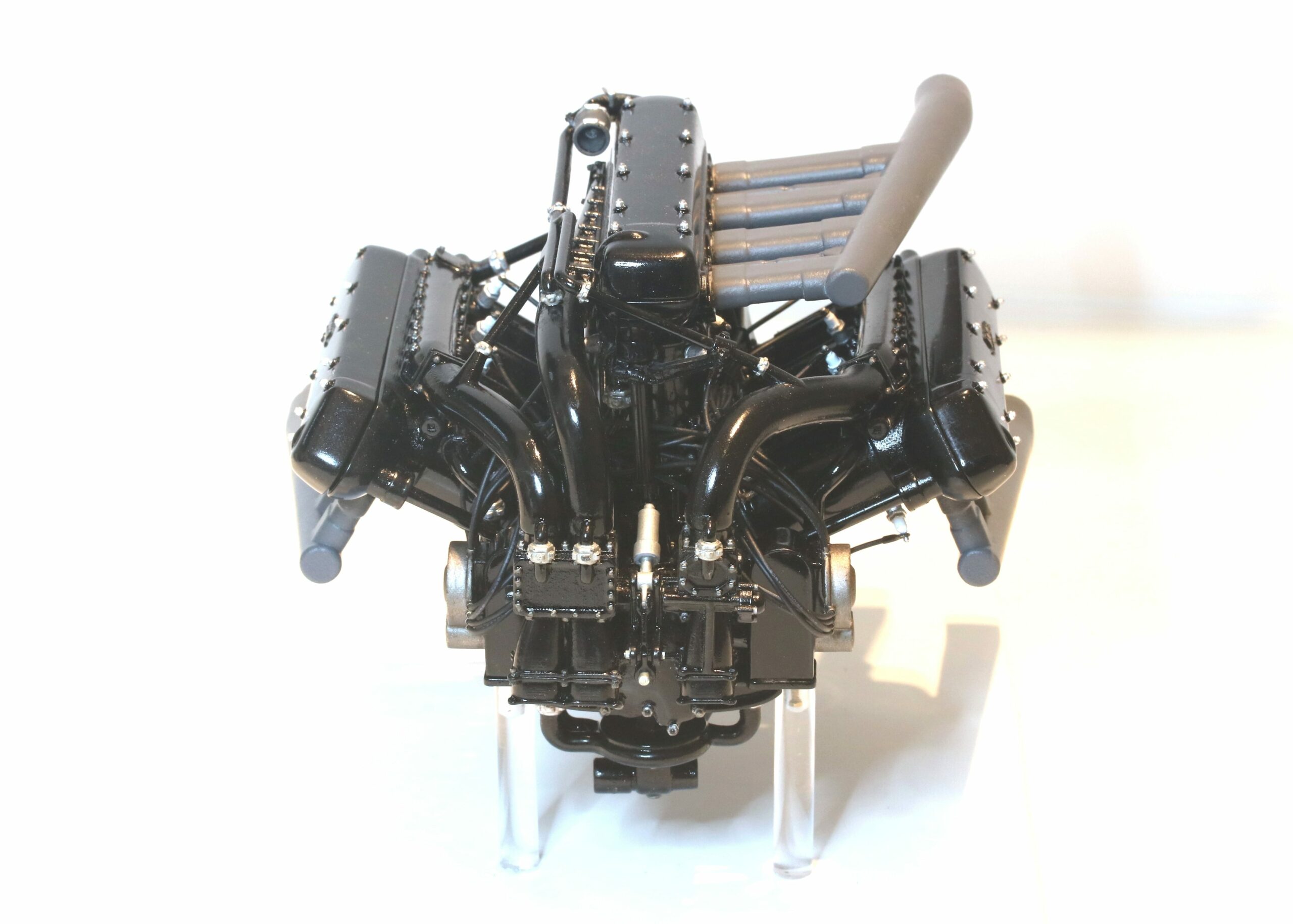

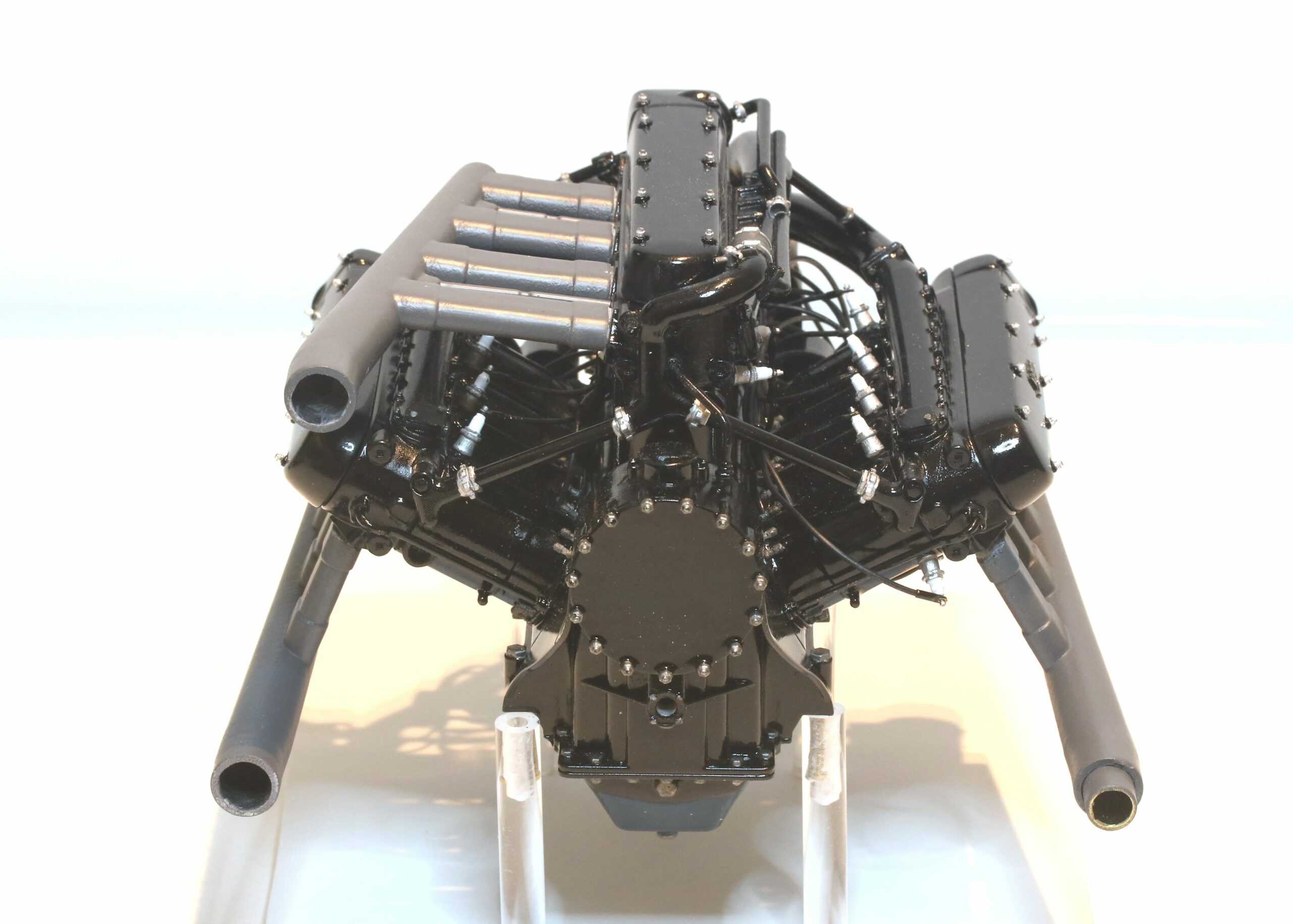

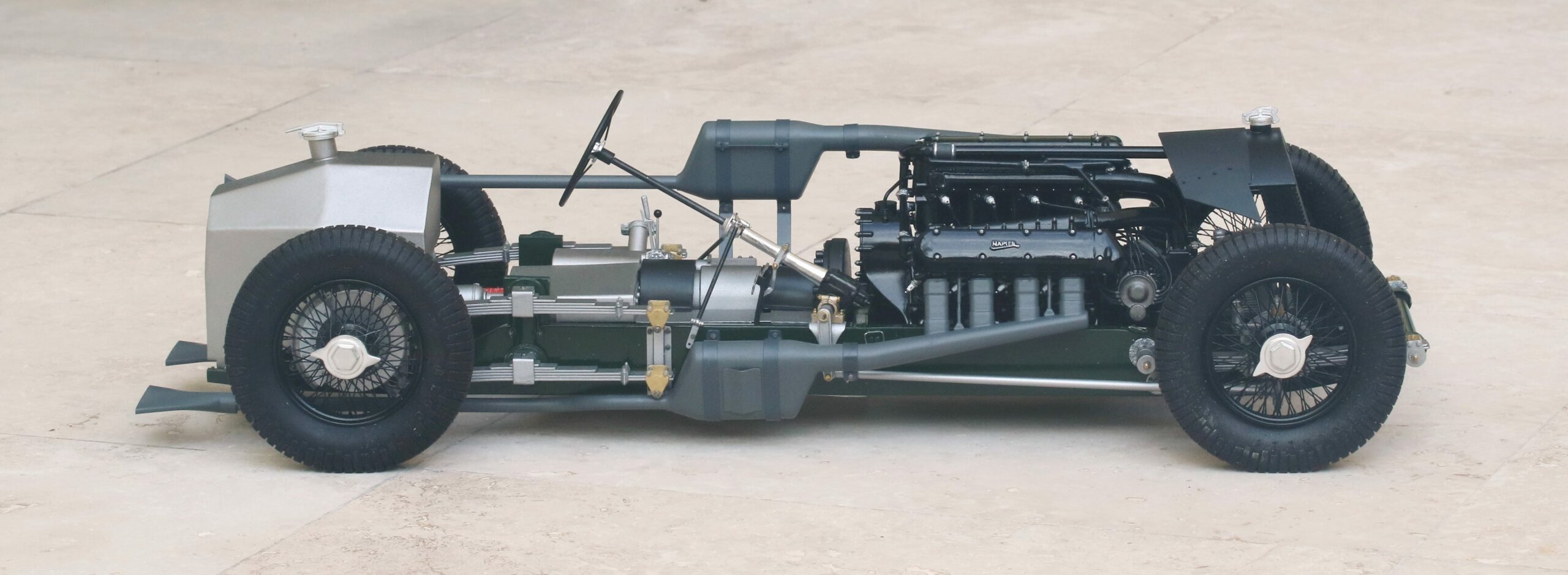

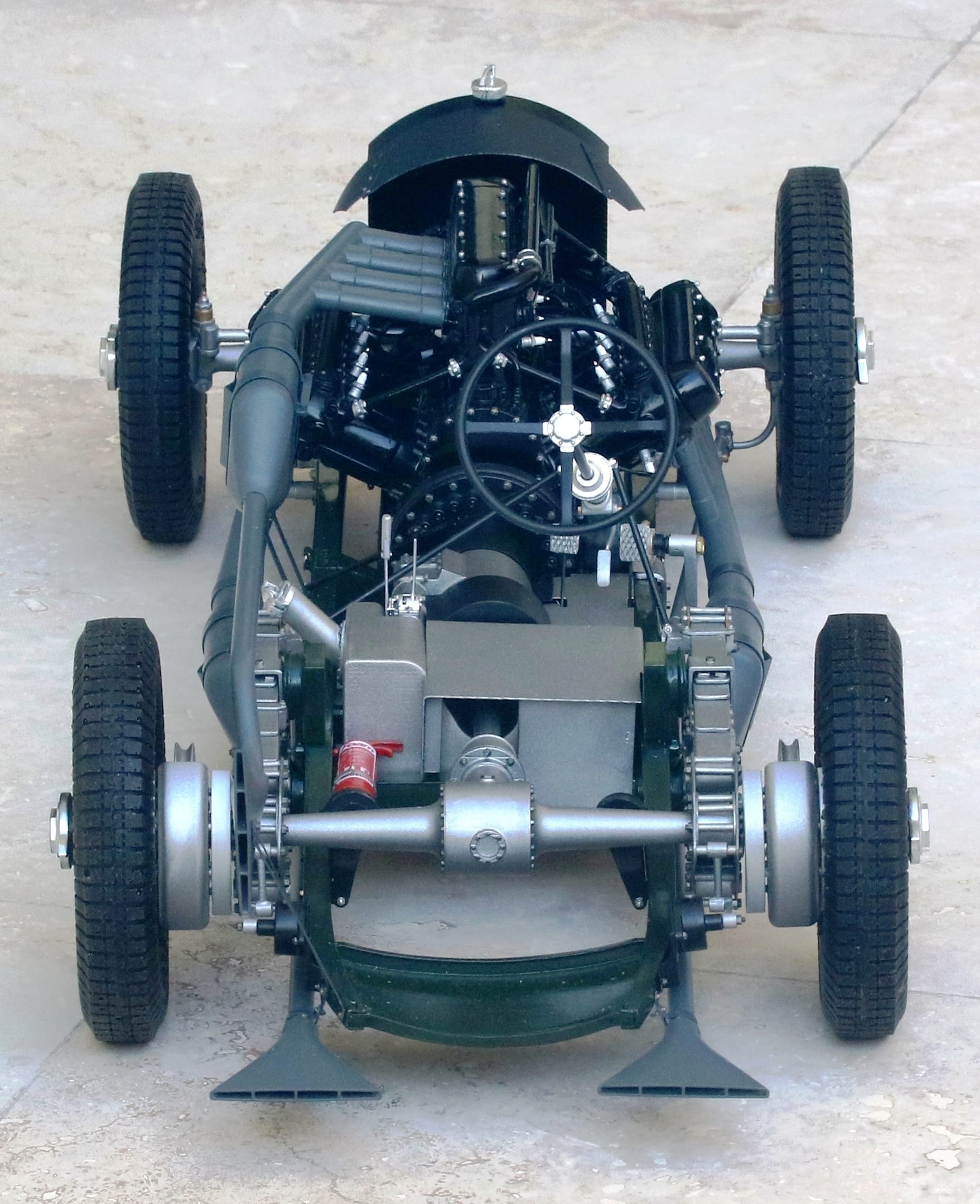

Napier-Railton 1:8 Scale Model

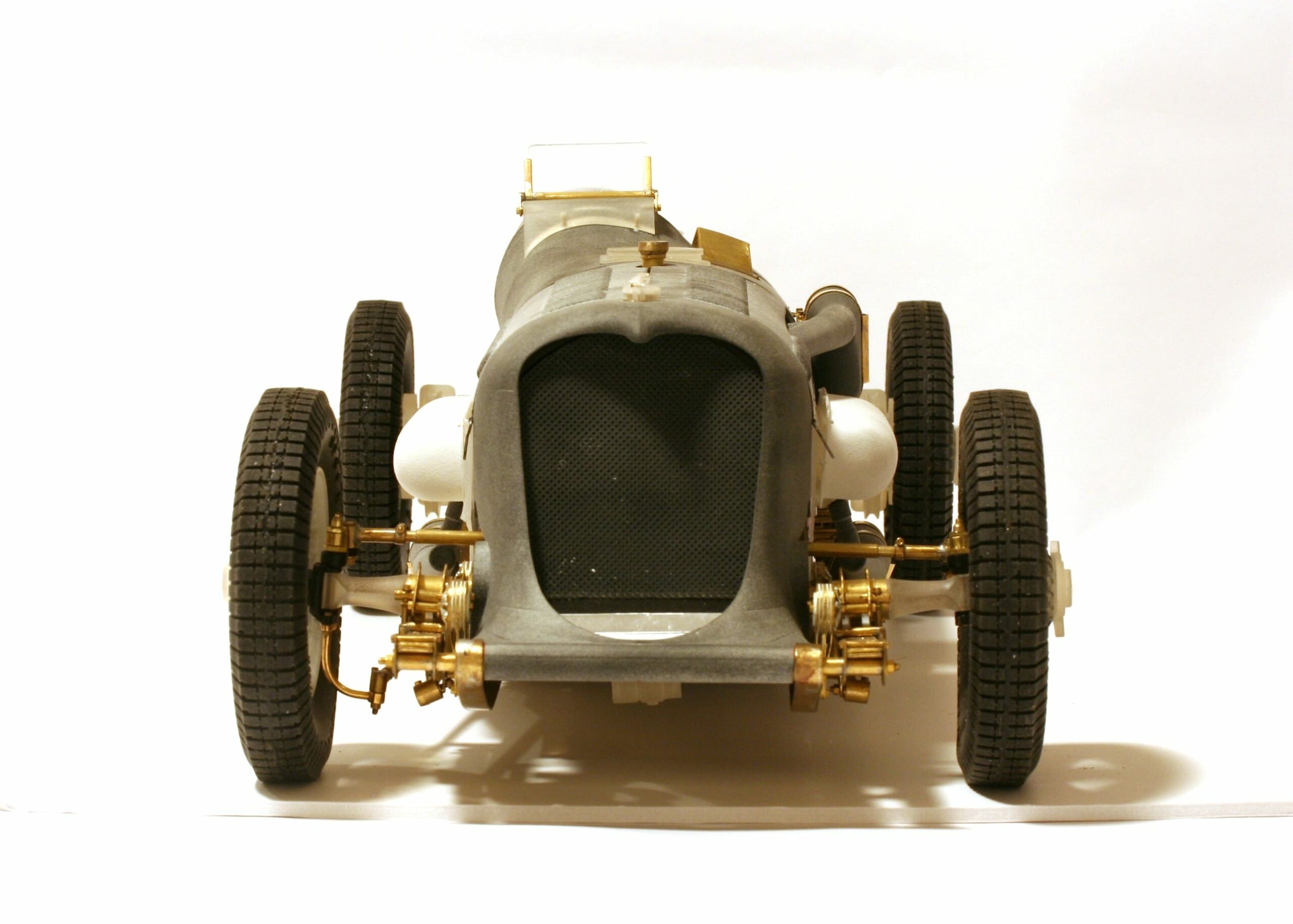

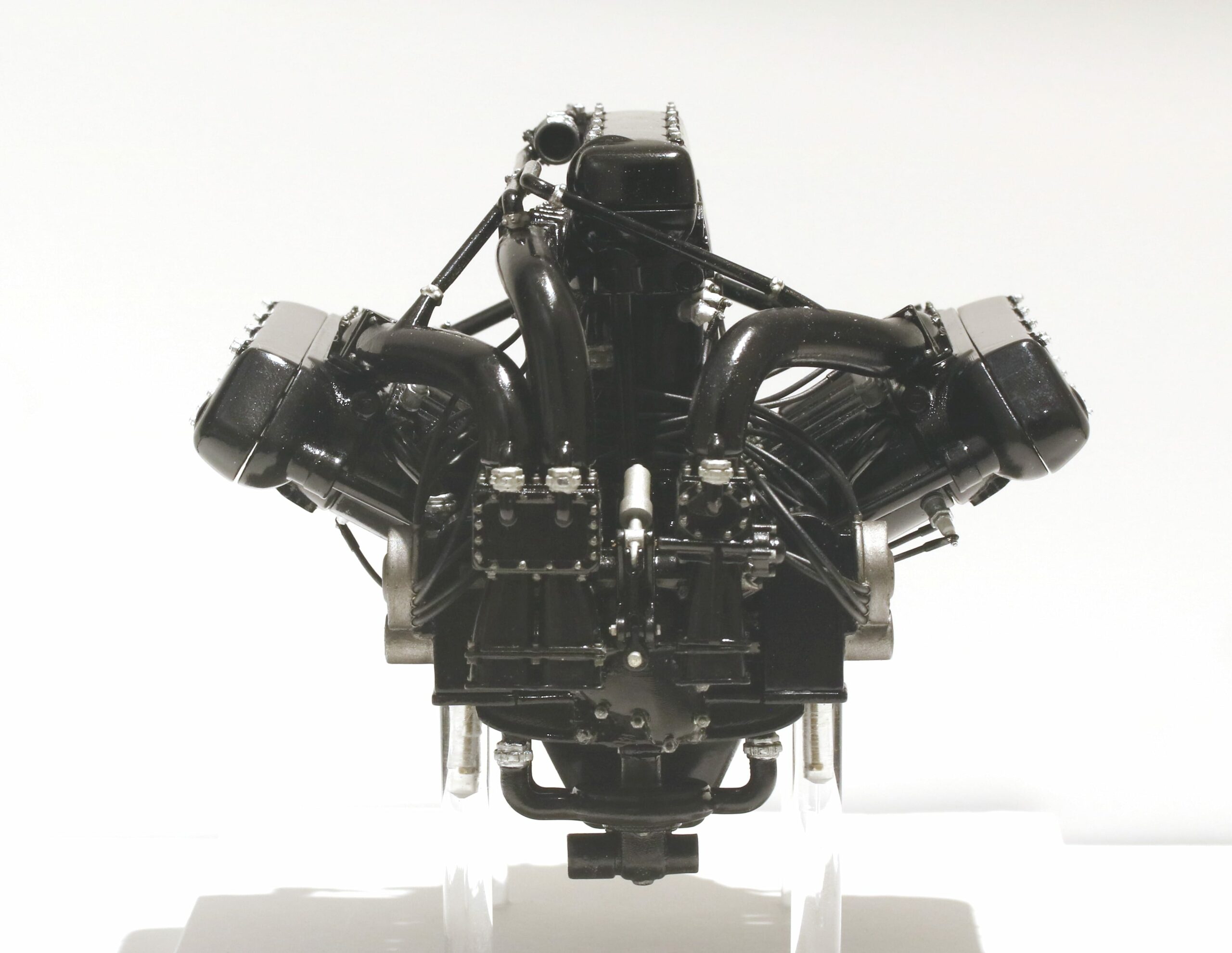

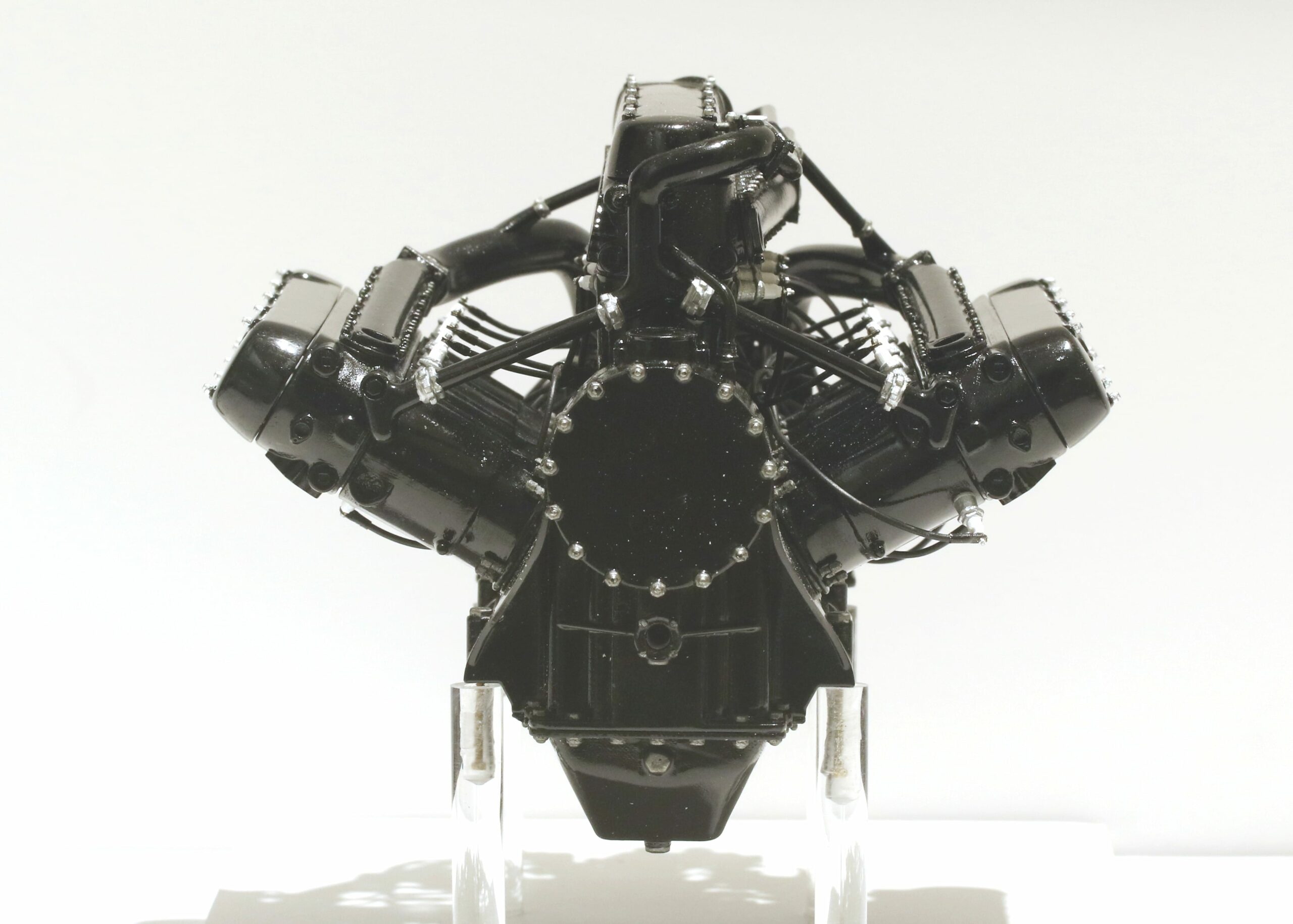

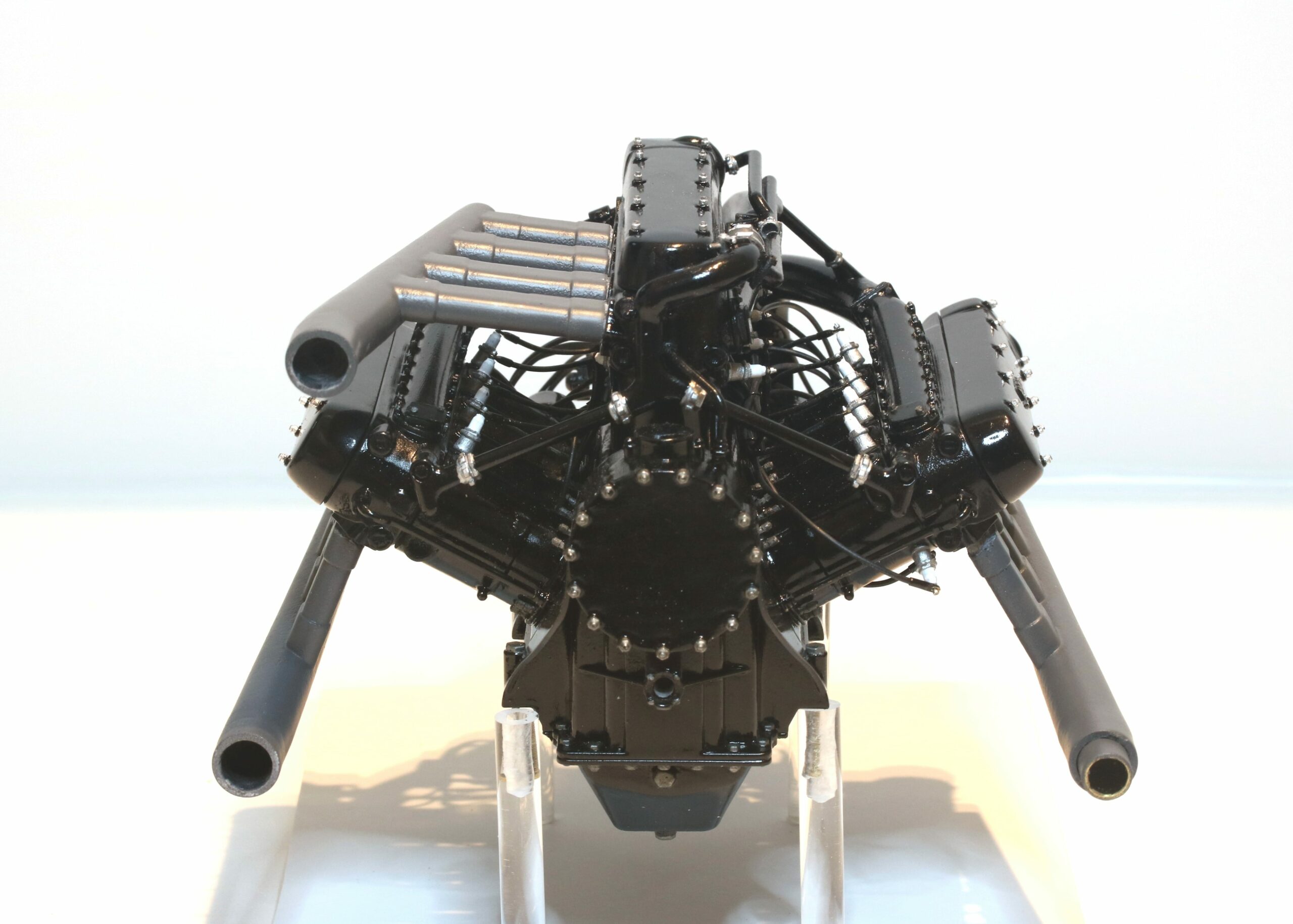

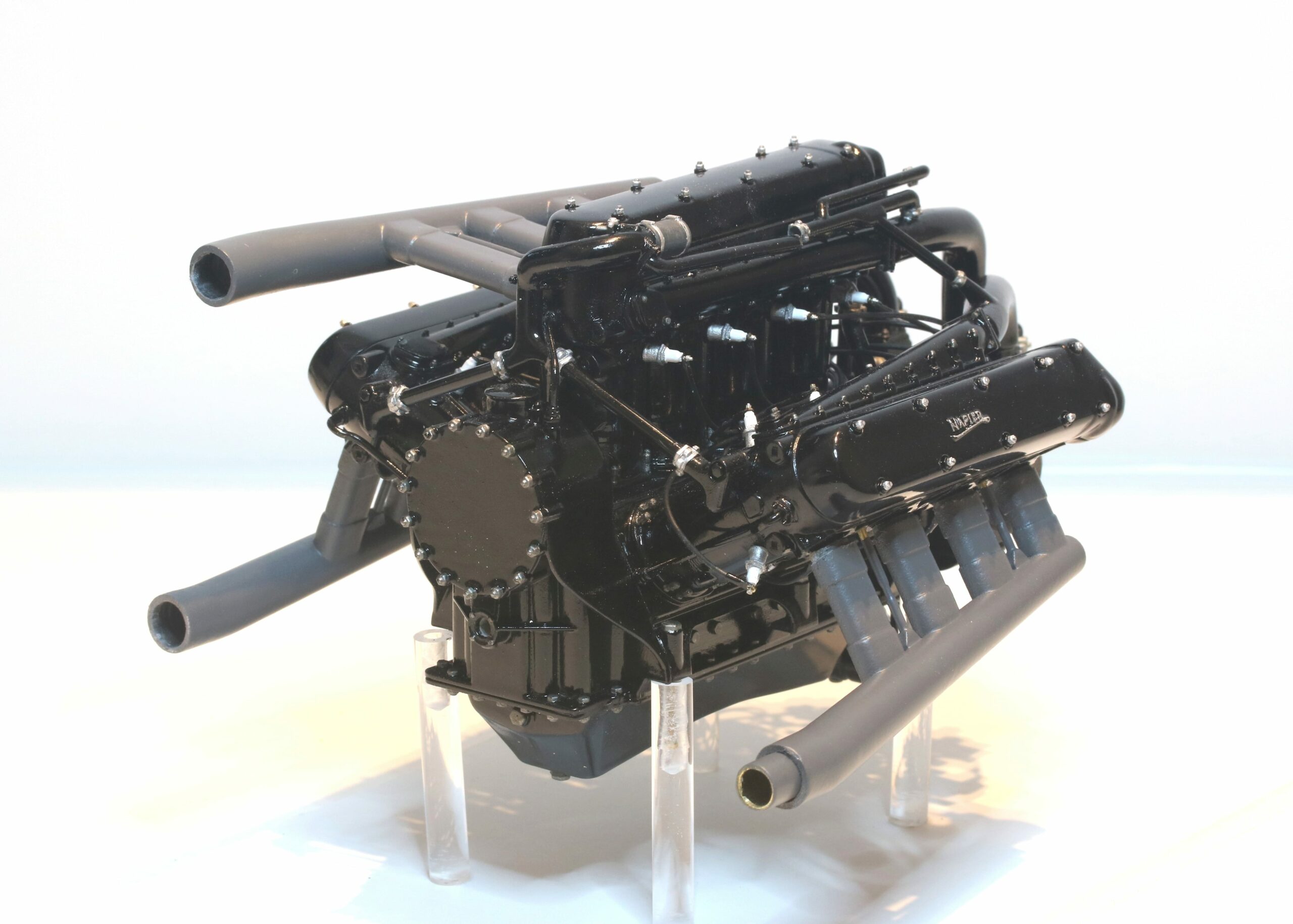

In 1935 the Brooklands race track, just outside London, was the venue for very popular motor races. It’s banked track allowed for phenomenal speeds at a time when most ordinary cars could barely reach 60 mph. That year a Napier-Railton racecar, designed by Reid Railton and powered by a W-12 Napier aircraft engine set the fastest lap time ever with an average speed of 143.4 mph. All this on a notoriously bumpy track in an open seater with just a bucket seat for the driver and no safety belt!

Sadly, the Brooklands race track was closed during WWII so the Napier-Railton track record still stands.

The 1930s were tumultuous times, both politically and economically. Despite that, the transformation of motor cars, from the staid upright carriage-like designs of the 20’s to the streamlined designs of the late 30’s was amazing. The fascination with that transformation led me to model a couple of Rolls-Royce Phantom IIs, based heavily on Pocher kits, but with lots of modifications including adding missing detail and correcting mistakes. Subsequently I scratch-built a 1:8 scale 1935 Austin Seven. After that the Napier-Railton seemed like a fun project.

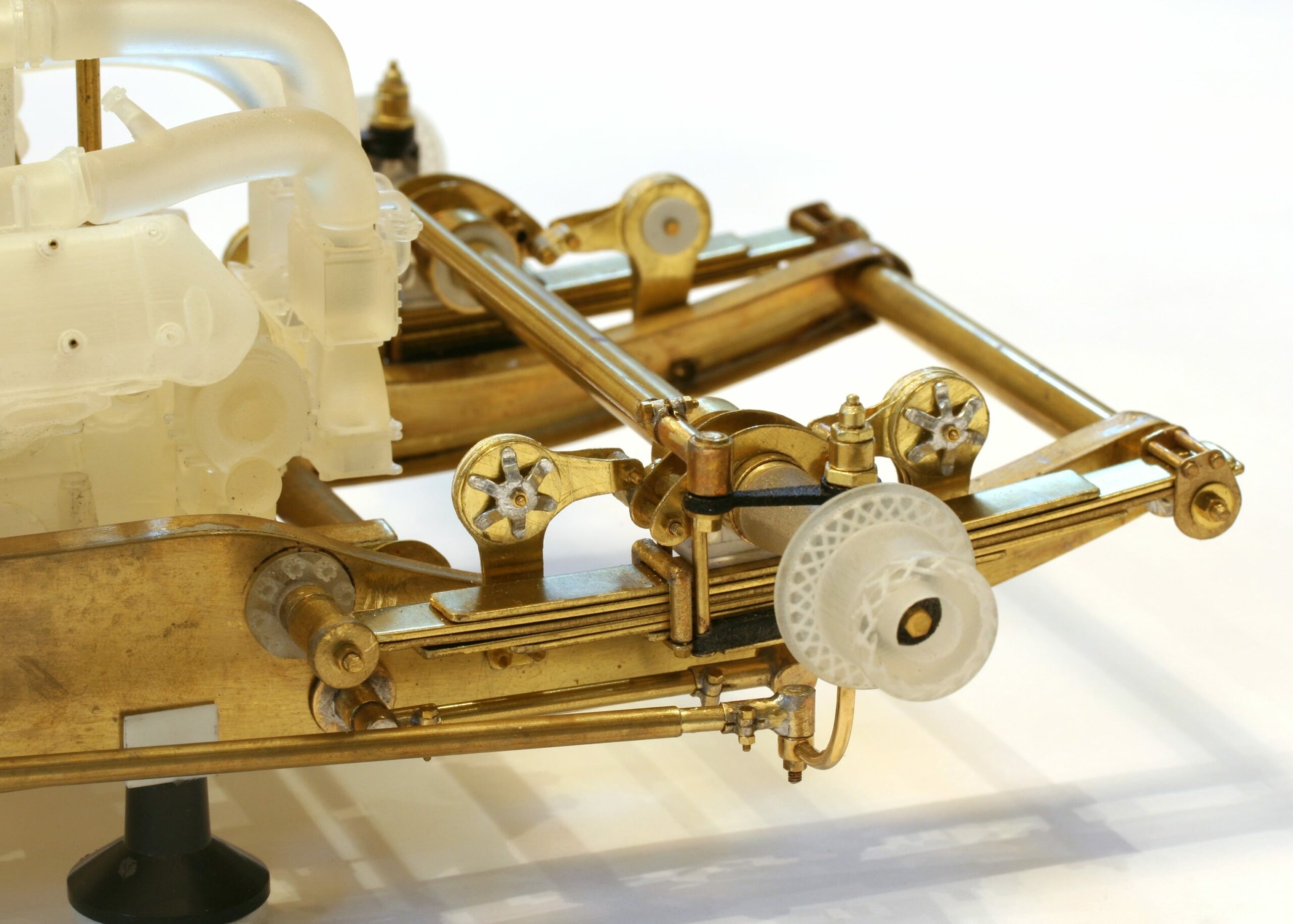

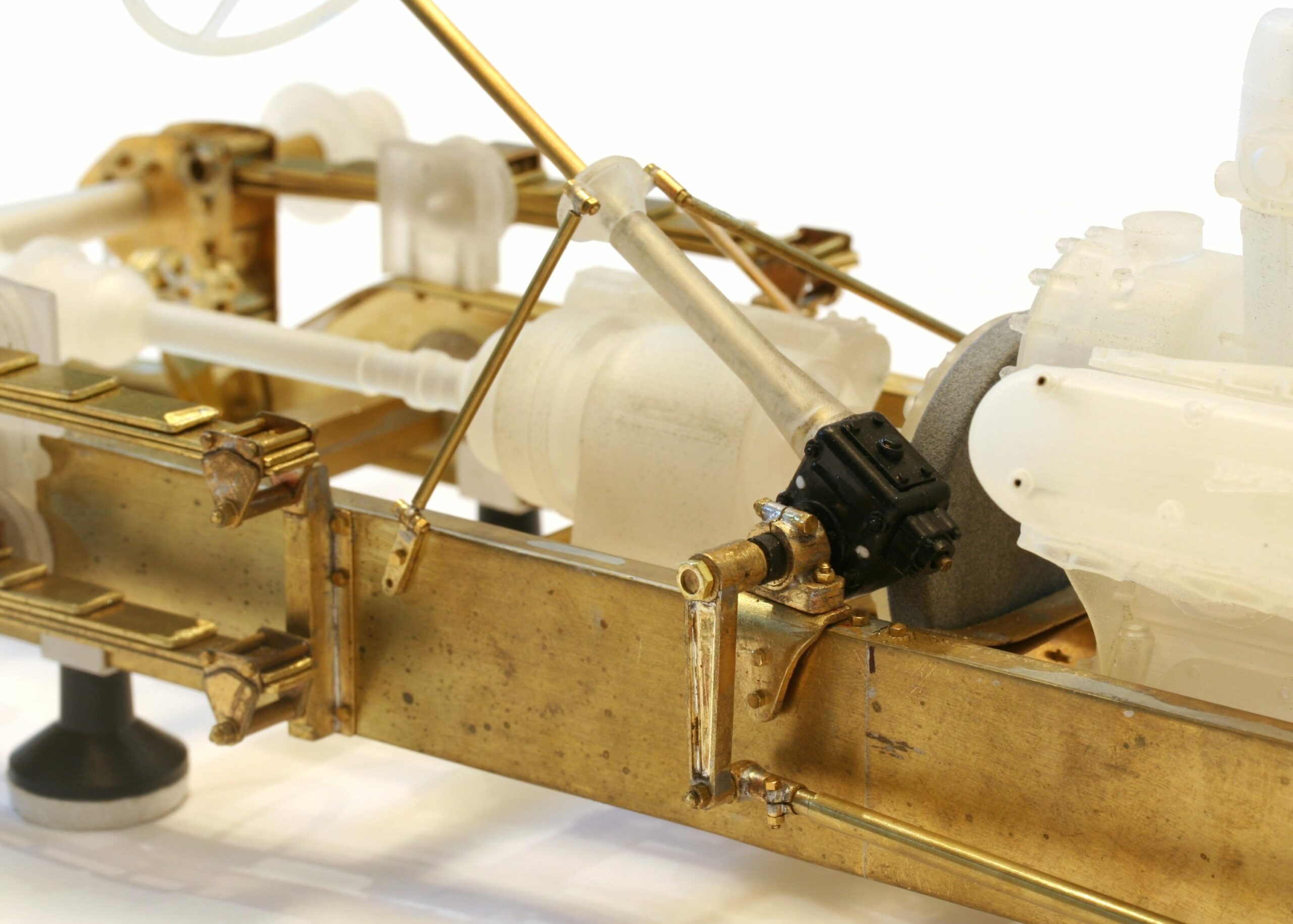

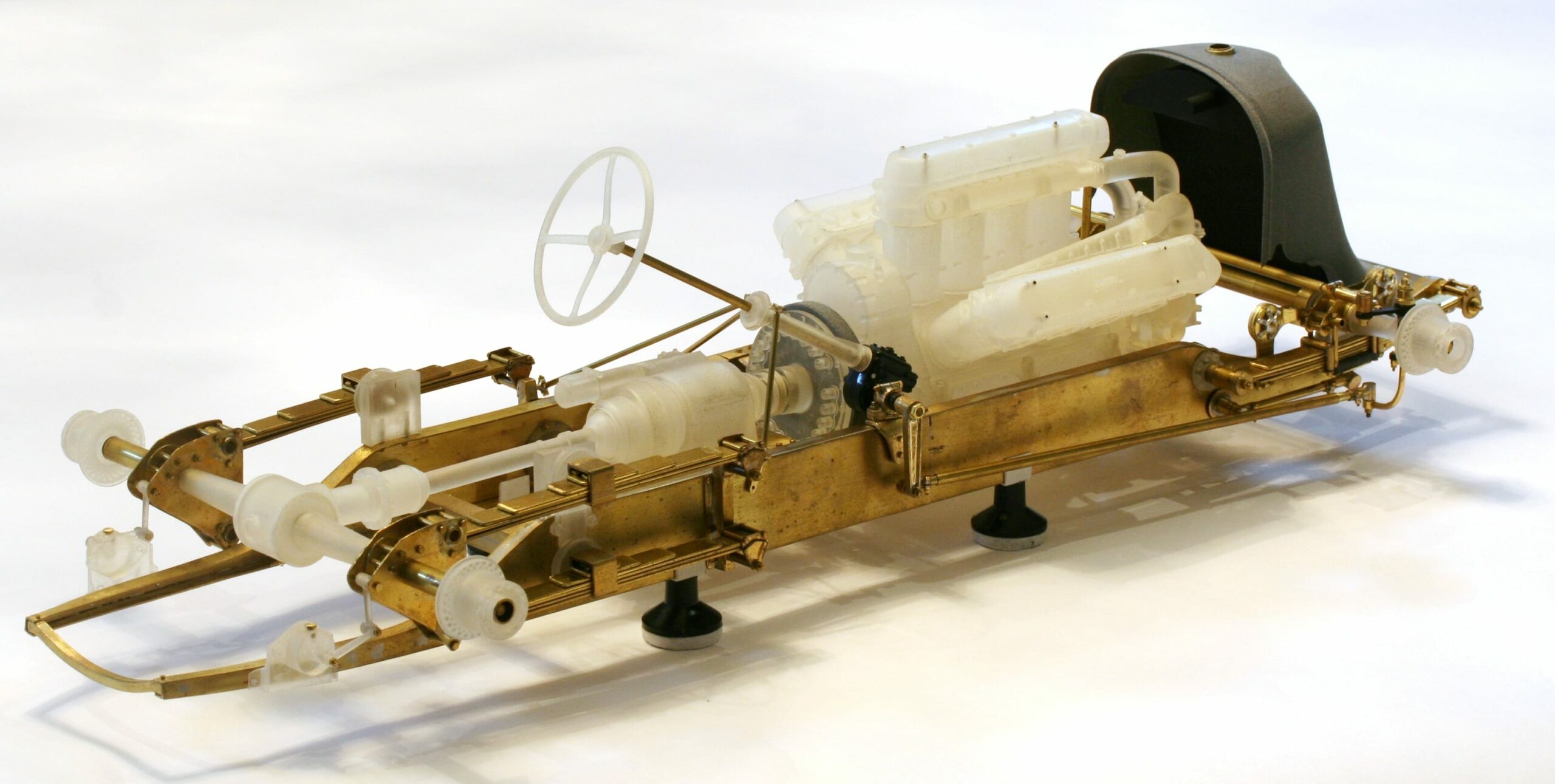

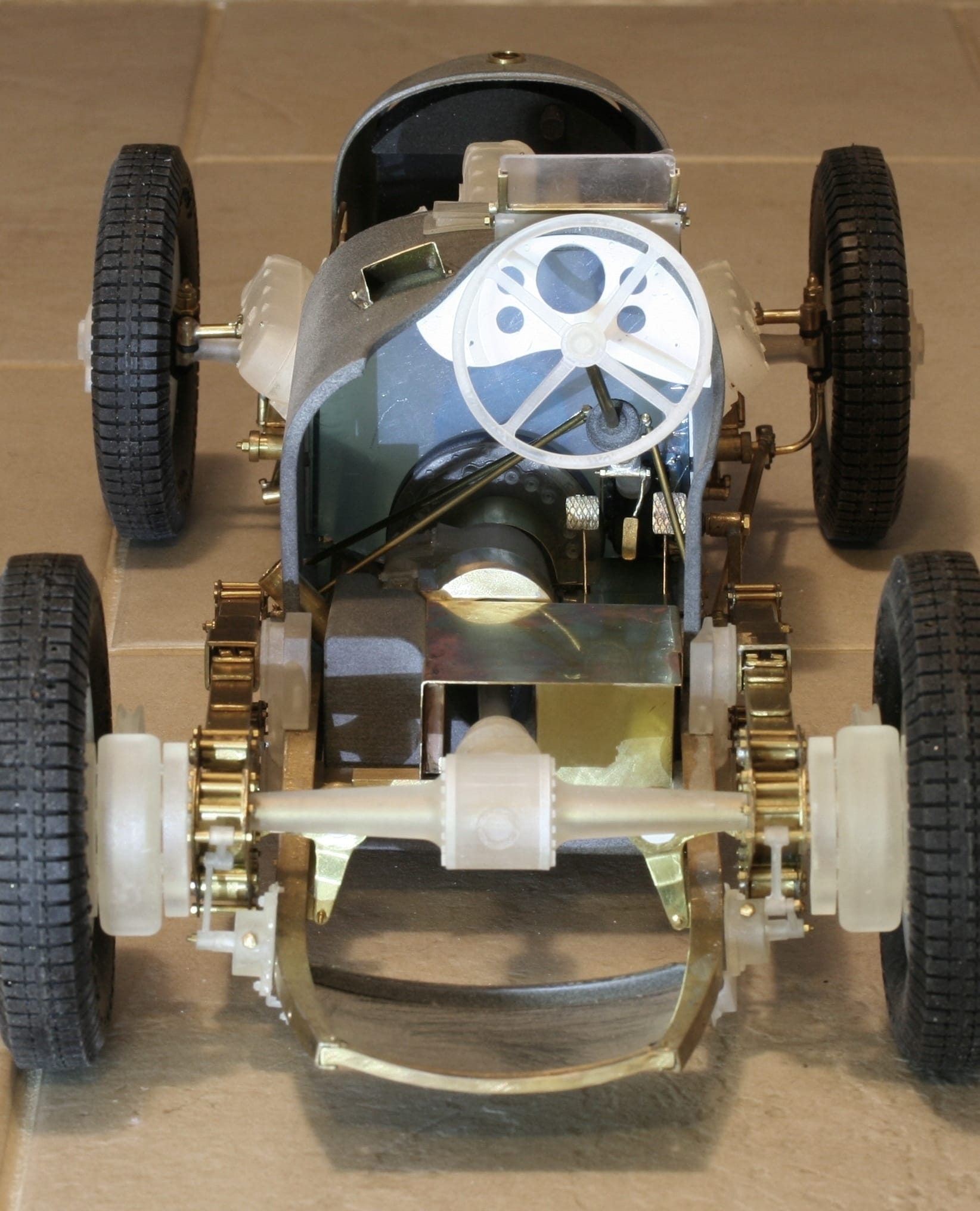

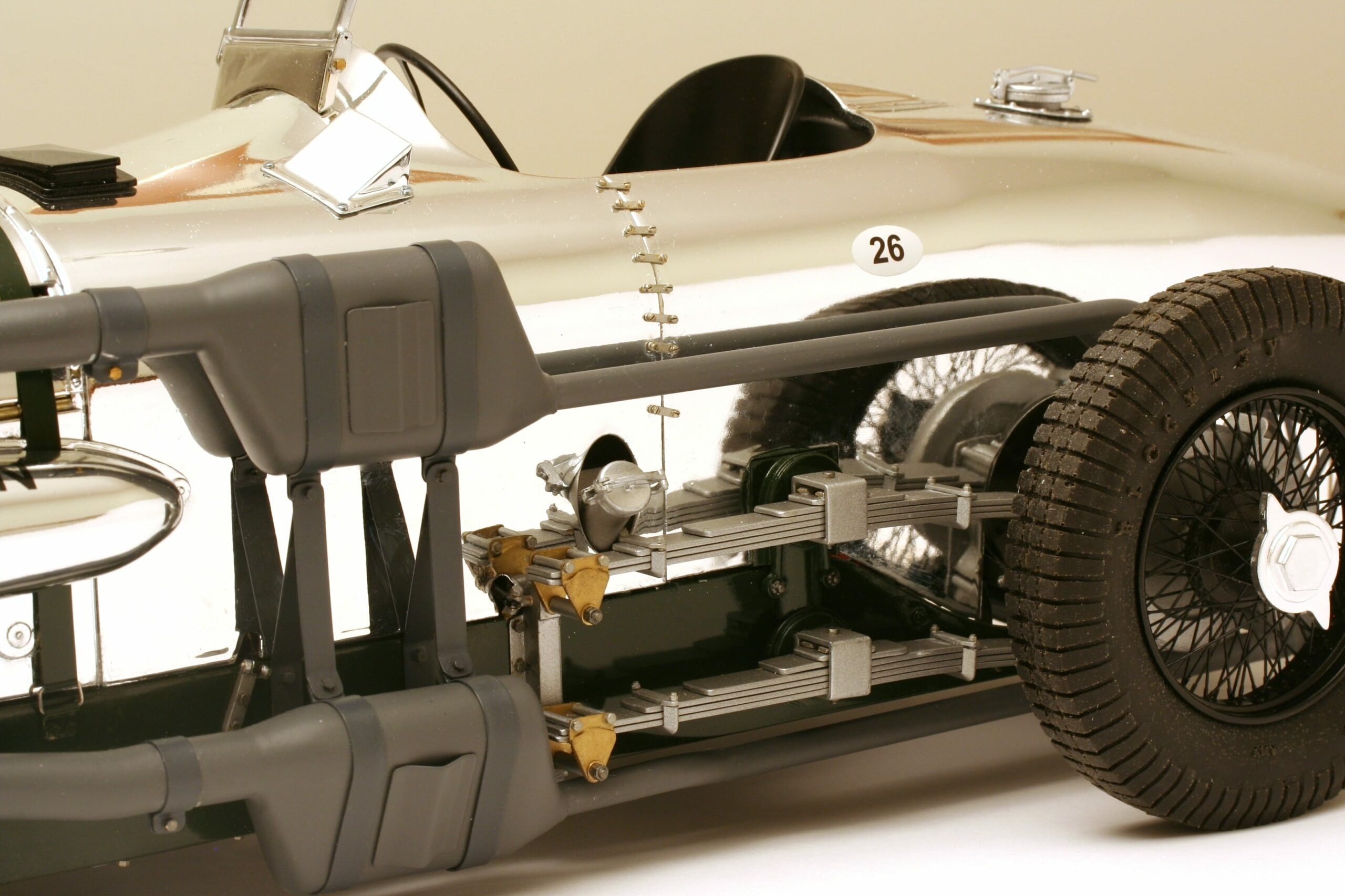

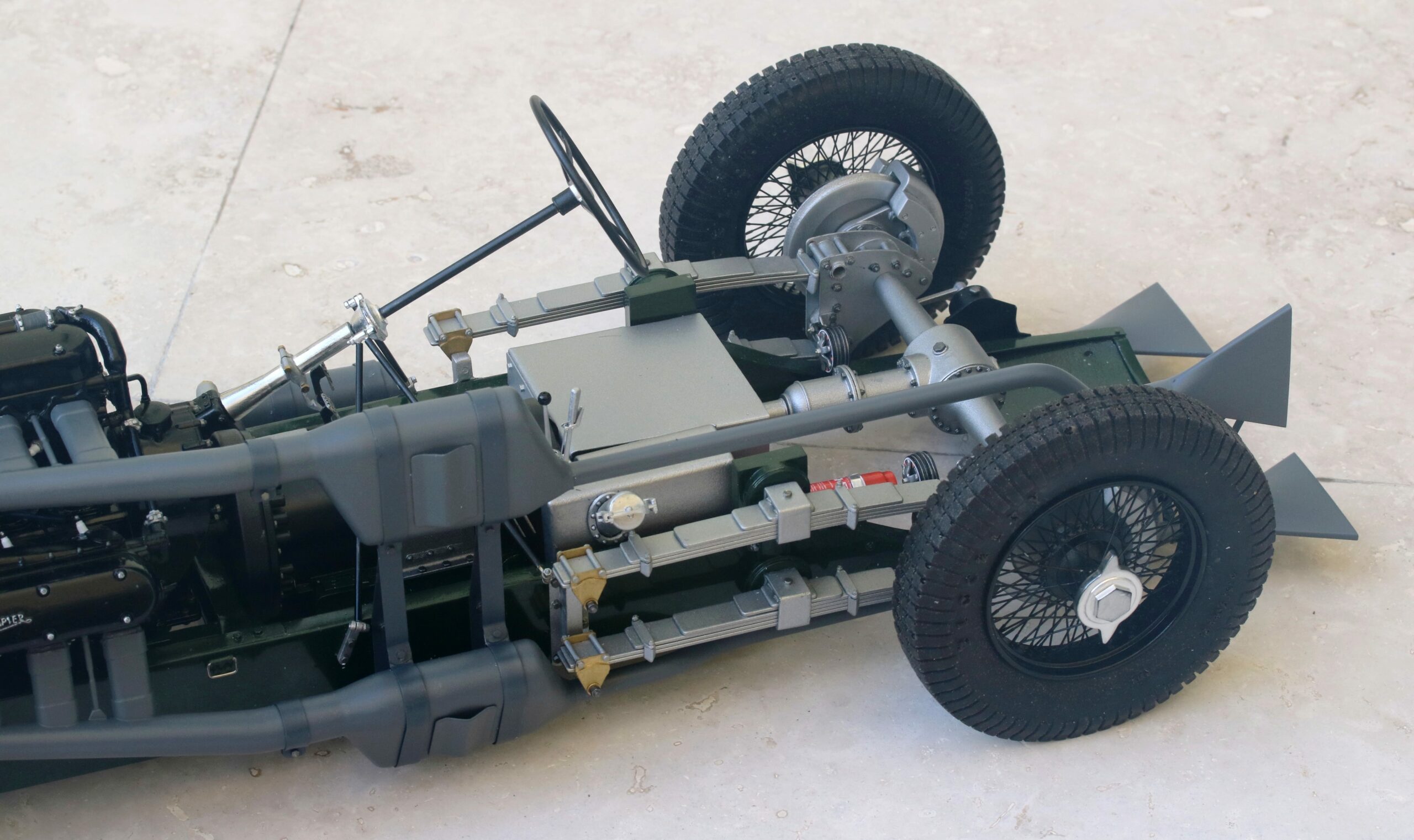

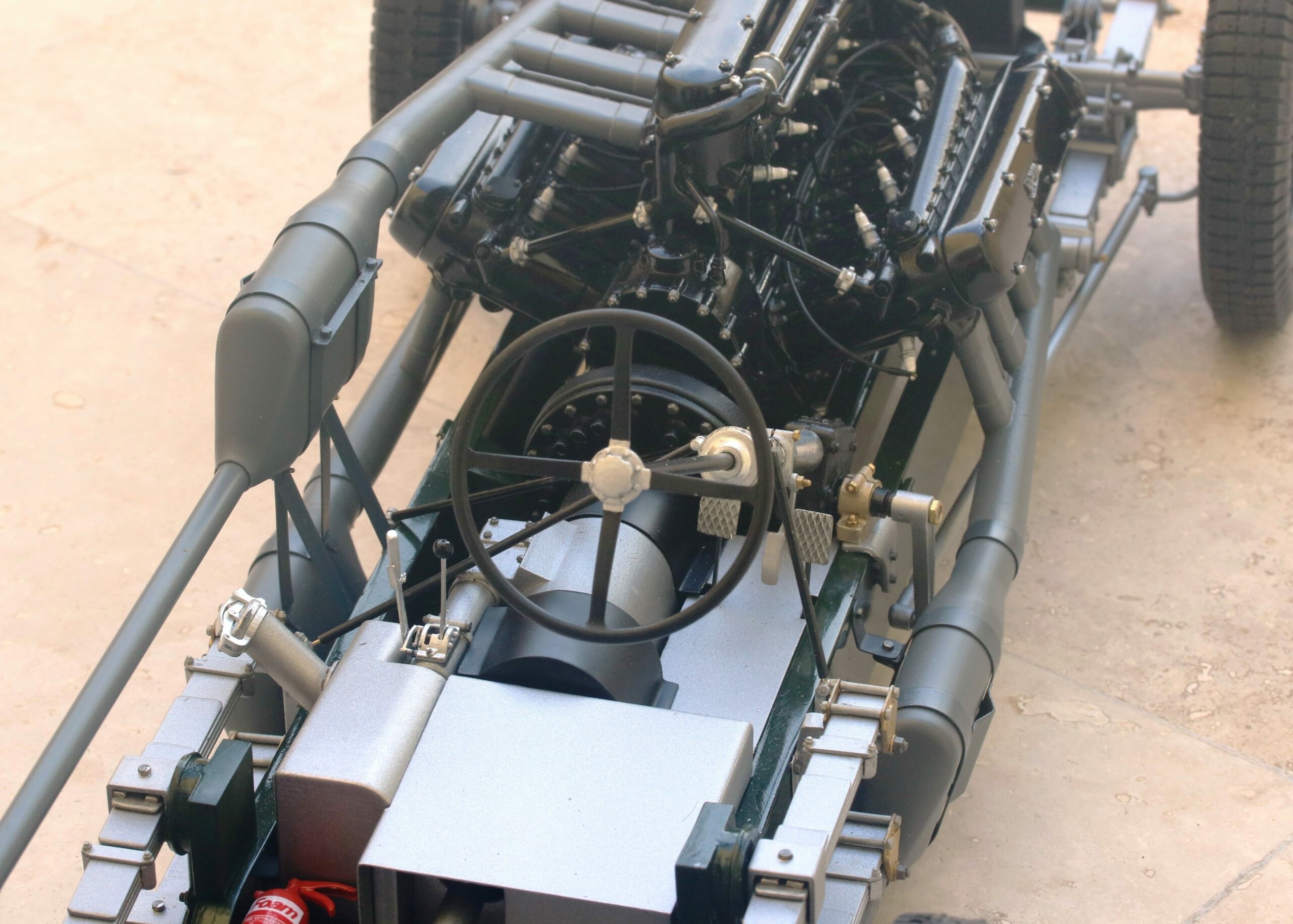

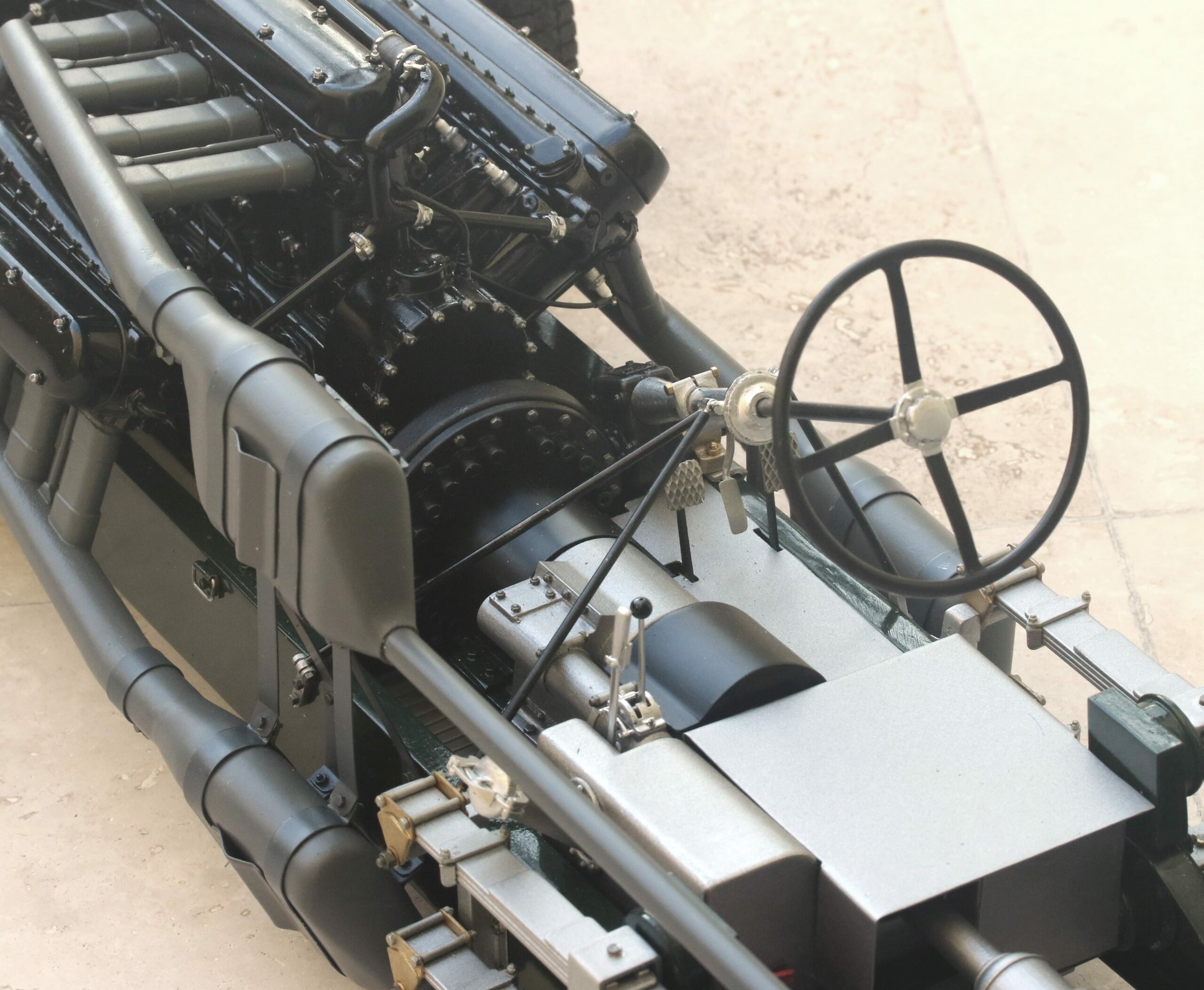

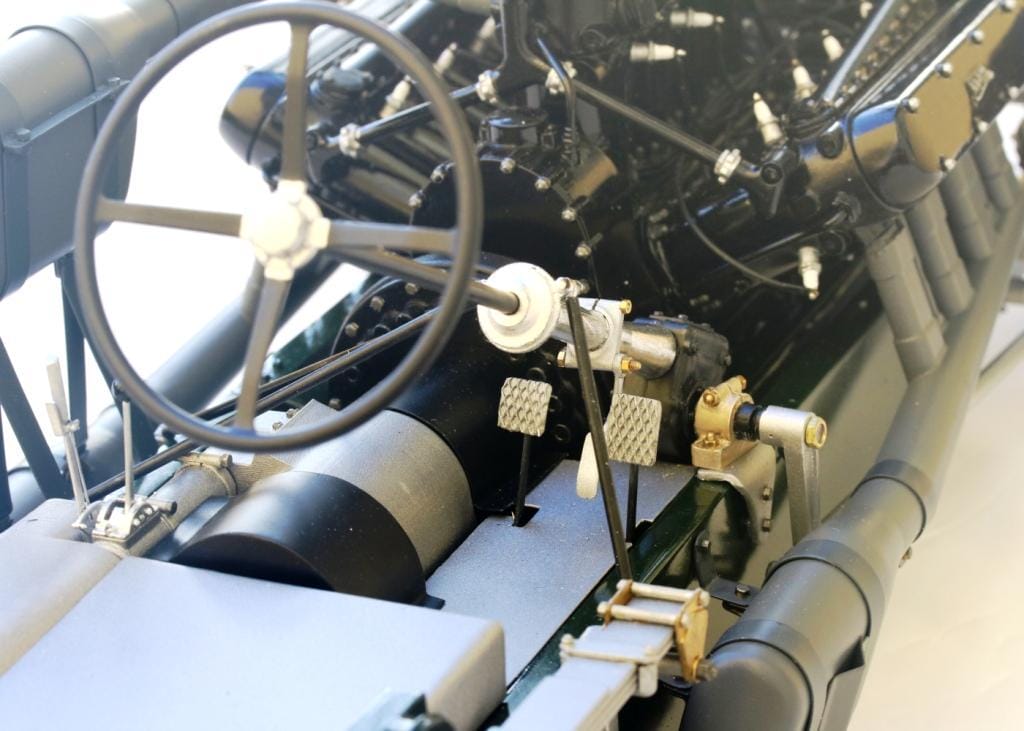

Necessarily, the Napier-Railton would have to be completely scratch built. But I had already taught myself CAD and 3D printing was readily available, so the biggest task was creating a reasonably accurate set of drawings. The prototype exists, at the Brooklands museum, but because of COVID visits there proved impossible. Very few drawings of the chassis exist, but the engine is well-documented since it had been the mainstay of the RAF since 1919. Fortunately, I did find a lot of photographs of the car online and I was also blessed with the generous gift of some private photos that showed much of the detail of the car. The rest was triangulation based on the few measurements (wheelbase, track, tire size, etc.) that were documented.

The chassis is largely of brass construction but the engine, drivetrain and radiator assembly are largely built from 3D printed acrylic parts. The body panels were also 3D printed, in 0.8mm thick nylon, since my skills in brass forming would not be up to the task.

Like all highly detailed models, construction takes time. But I think the result was worth it!

You must be logged in to post a comment.