Engine Turning

The following comments will explain how I made the engine turn motif for my Bugatti engine and other components

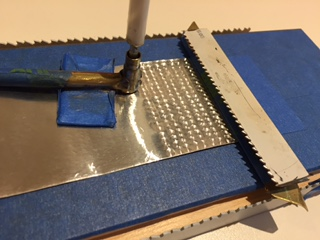

The picture shows the early stage of engine construction.

The next picture shows the tool I have built and the material required to replicate the century old method of decorating metalwork.

It is actually a fairly simple process.

What you are trying to achieve are basically two things, one being these little swirls for the patern and obviously the equals spacing of them.

First on your list, you will need to find bright polished aluminum duct tape.

This material is used by most HVAC technician and should be available at all good construction and renovation material supplier and comes in a 2 inches wide roll.

I have selected this product for several reasons.

First it is nice and bright but also very malleable, secondly it will reasonably stretch and conform to most of your plastic components and thirdly, the sticky backing will allow for repositionning in the early installation steps should you need to.

Once installed, it can be polished (burnished) and will look like an actual aluminum part or better and brighter.

I have used this product on many parts over the years.

You should however pay attention to the part’s preparation as this stuf will show every details, which may not be what you want to achieve if the preparation is not up to par. Every mark or loose dirt will be visible through and should it be traped under the tape. The good neews, it is removable should you need to but it takes some work if it has been burnished in place.

As an example of flexibility, the full contour of the cam box cover in the previous picture is made out of one single piece of tape.

Now the the tool.

Yes these are hacksaw and demolition tool knife-type saws.

When you’ll go put to buy some, what your are looking for is equal thoot spacing. Some saws have varying thoot size and spacing.

I like 10 per inch (or approximately) format. It allows for some overlapping swirls, and this is what you want.

Using a left over piece of hardwood floor board, I attached a saw blade on each sides to control the logitudinal spacing increment (along the tape) for equaly spacing the rows of swirls as the cross piece move along the board (from thoot to thoot) to create each new rows of the swirl motif.

For the side to side control, to creat the lines of swirls, the cross piece also has a saw blade attached, where the actual swirl creating tool will move from tooth to tooth, here again to control the spacing of the swirls.

The aluminum lape is simply attahed with masking tape at each ends on top of the board.

You will want to protect the tape with a cardbord piece that you will slide along as you move the crossbar and the tool. The aluminum tape is fairly fragile and it will get damaged as you proceed along it.

Any mark will not be hidden by the swirls, so care should be taken to prevent damages.

The trick is to move the swirl tool from thoot to thoot from left to right and make swirl imprints (I will explain in a minute) and once a row is complete, move the cross bar one thoot equally on each side and so on…

You should be able to make a 2 ‘’ by 6’’ piece within 30 minutes of work.

I like to clean the stone after each row. Simply run the stone flat over a medium course nail file to clean it.

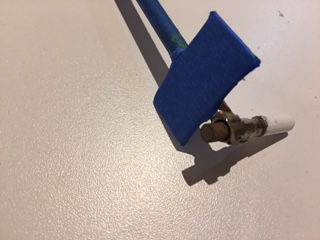

Now the actual swirl making tool.

Dremel 3/16 inch, cylindrical aluminum oxide grinding tool model # DRE8153

The stone is held vertically in a brass tube or sleeve (loose fitting). The sleeve is attached to an arm with a flat foot at 90 degrees in both X and Y axis in order for the flat end of the stone to be held flat on the aluminum tape as you work.

I made a drive handle for the drive shaft of the tool with a piece of styrene tube.

A square pad is attached to the arm so that the tool stays flat on the working surface.

The sleeve has an protruding indicator tab that will follow the crosspiece thoot one by one. Should it be require, it will be easy to return and touch up one or more of the imperfect swirls and landing exactly on the spot.

The shaft of the grinding stone is also held in an appropriatly sized sleeve, but I would suggest making sure that it is not a thight fit. Let me explain…

To make a good looking swirl, you will need to rotate the stone by hand and wiggle the handle a little as you go. Even a small pressure may damage or tear through the aluminum.

Therefore, you will rotate the tool handle between your finger and thumb and wiggle the handle as you go through the motion.

It takes a little practice but it is not that hard to do.

The key word is consitency of pressure and motion from one swirl to the next .

So this is all the stuff you will need to make engine turn partern on HVAC aluminum tape all with a good and expected amount of patience.

Happy engine turning !

Daniel Archambault