Instructions for Assembling the Rolls Royce Wheels

by Dave DeBack

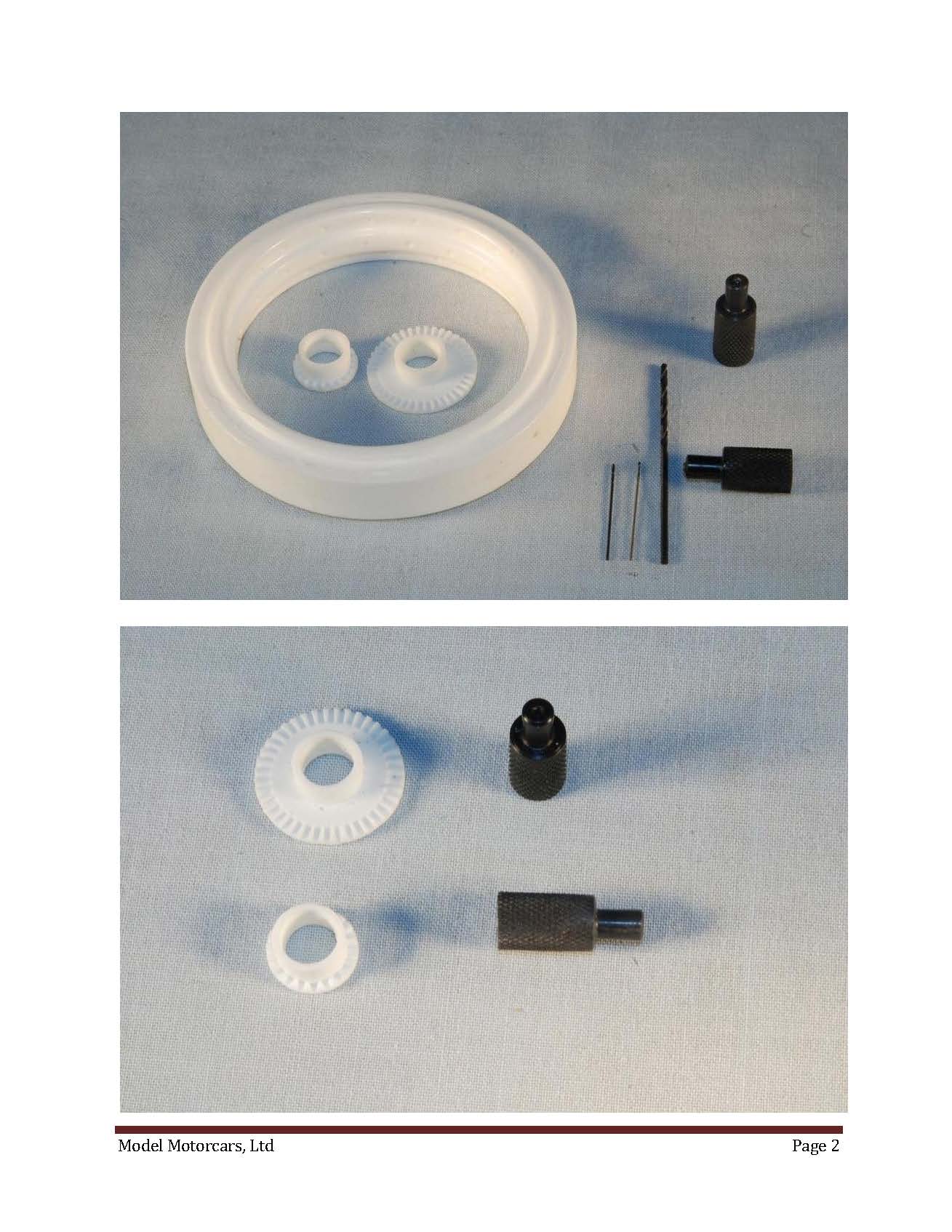

- Trim whatever flash is on the resin pieces and wash in soap and water. I’ve found resin can be tricky to get paint to stick sometimes.

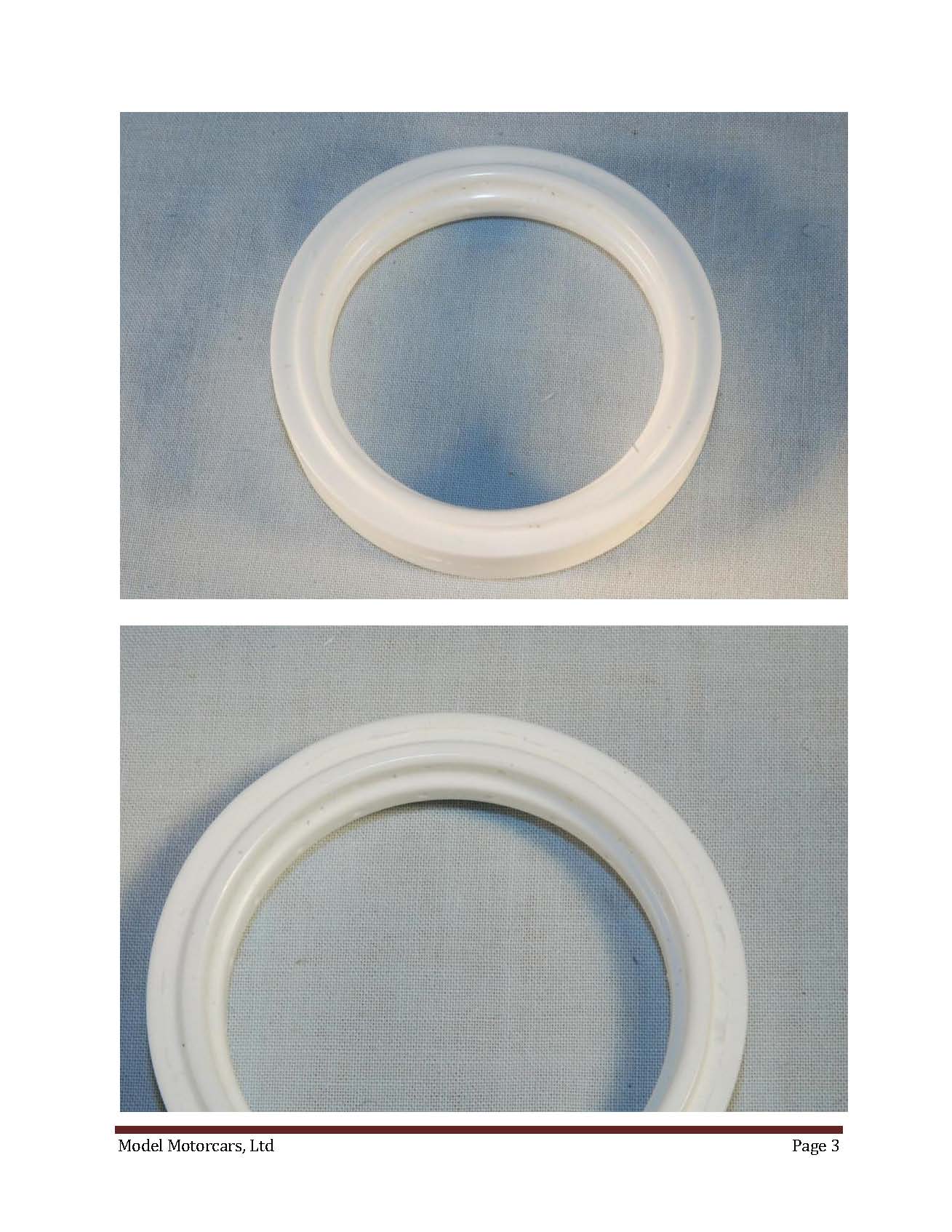

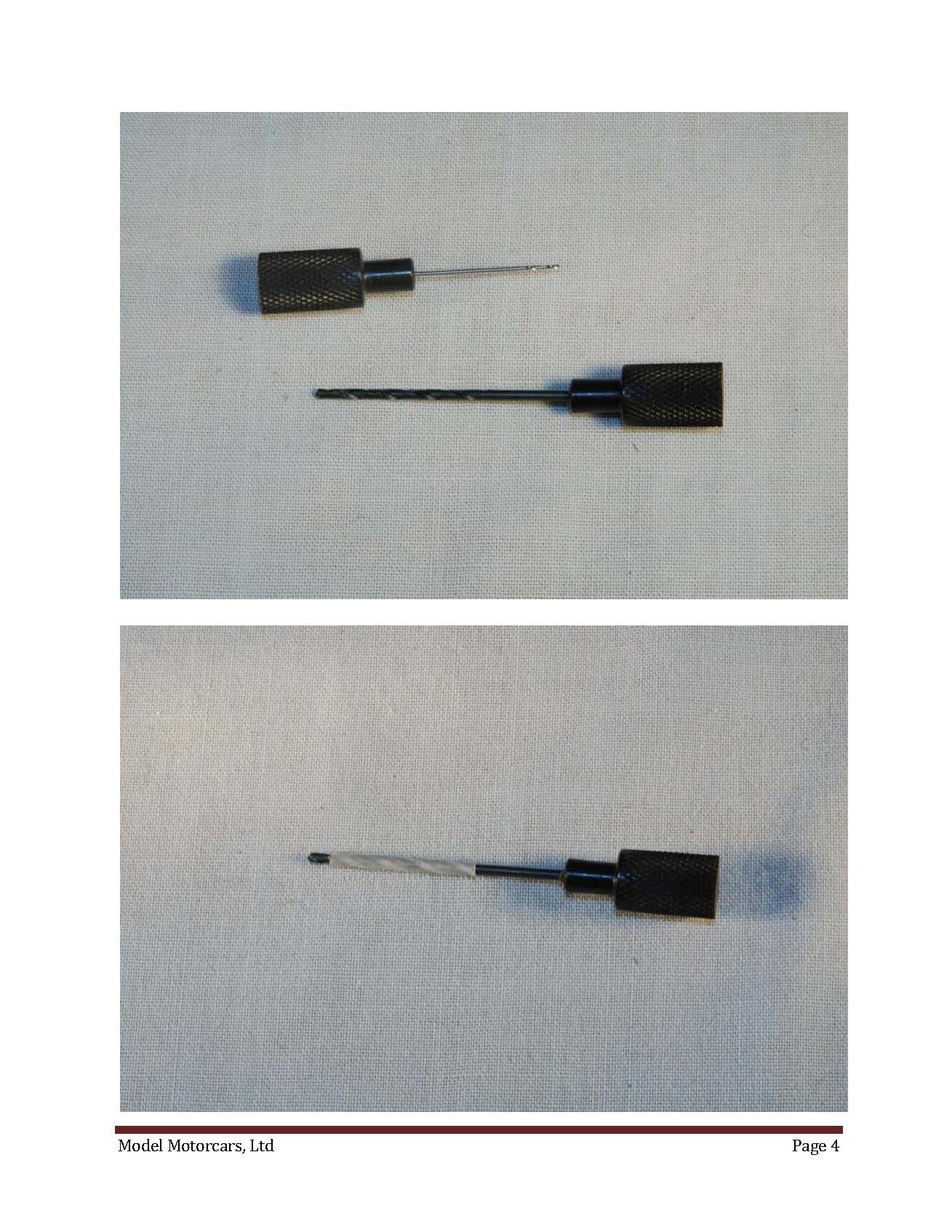

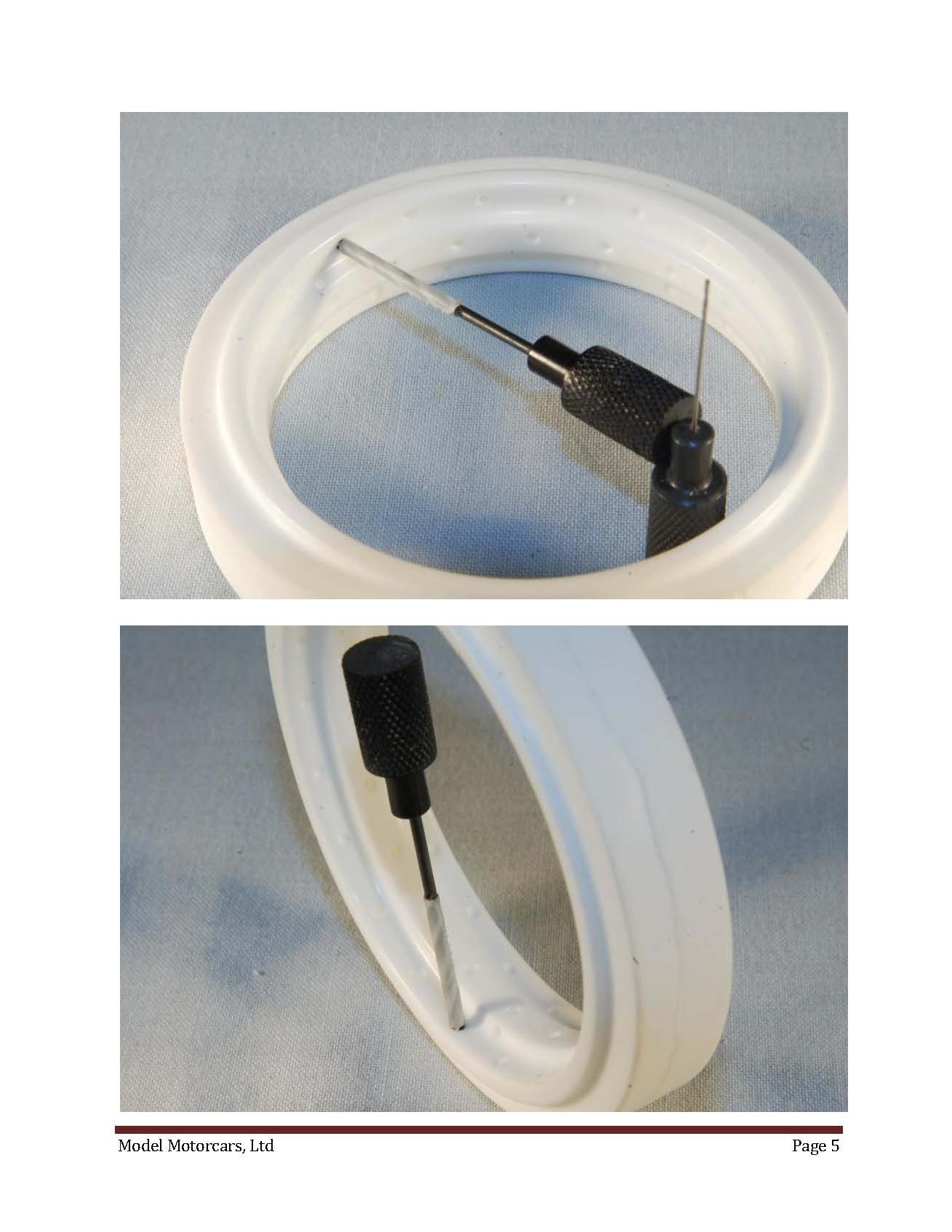

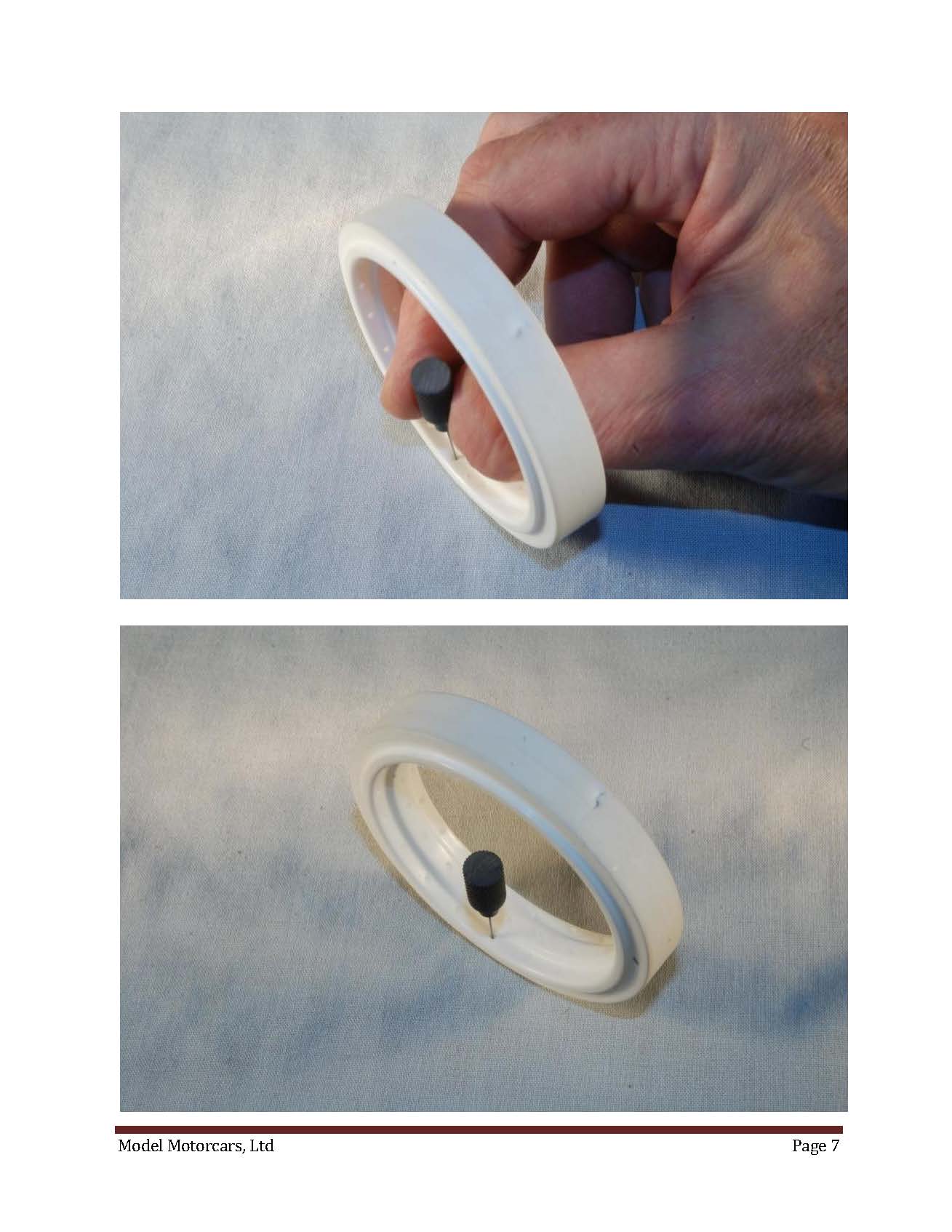

- Drill holes in drill handles and flue drill bits into handles (#54 & #76). Make sure hole is deep enough that drill and handle fit inside rim.

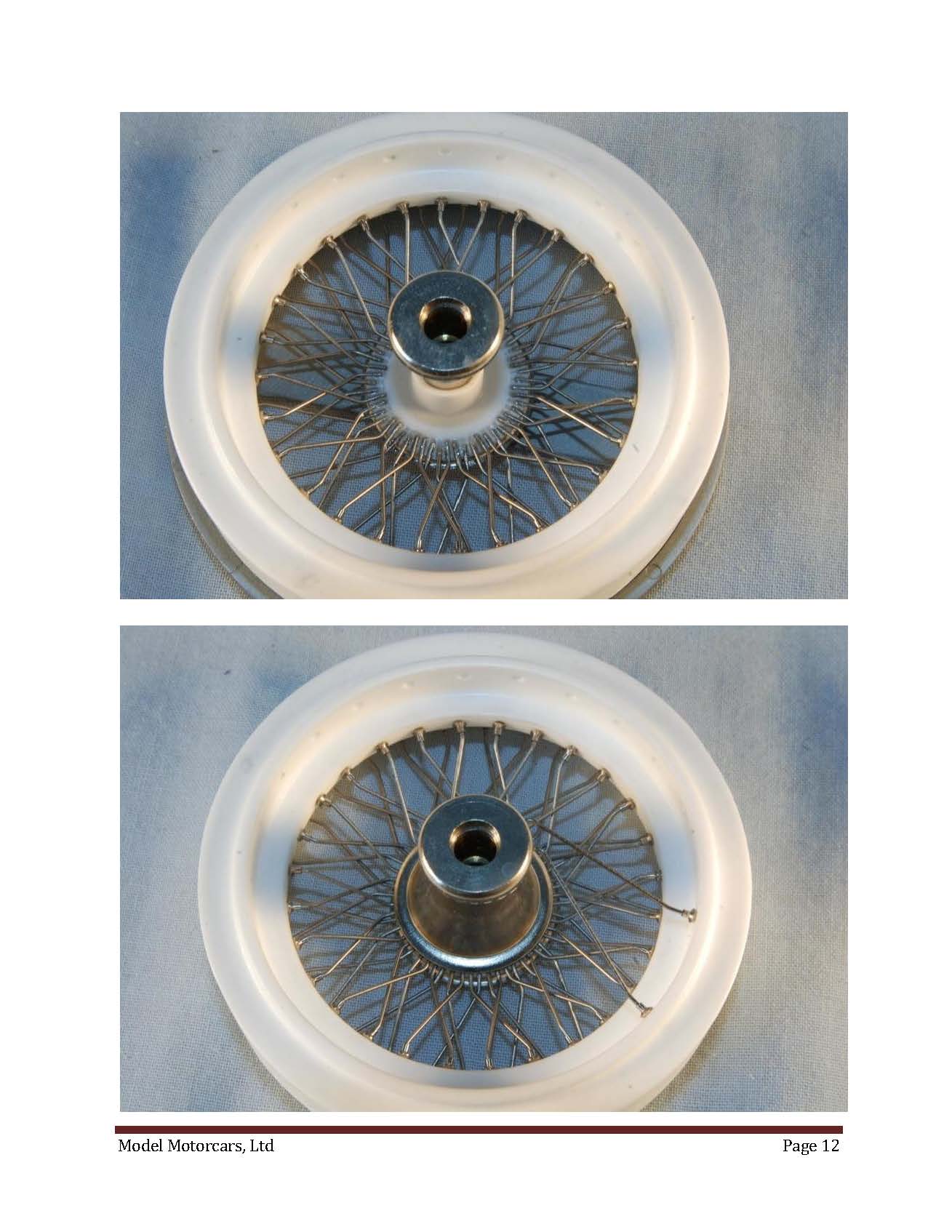

- I drilled all the nipple holes first (#54) to a depth of approximately 2mm. Deep enough for the bottom end of the Pocher nipple to seat into the rim.

- Then drill an additional 2mm deeper with the #76 bit (two are provided in case one breaks). I used the #54 bit for the valve stem hole.

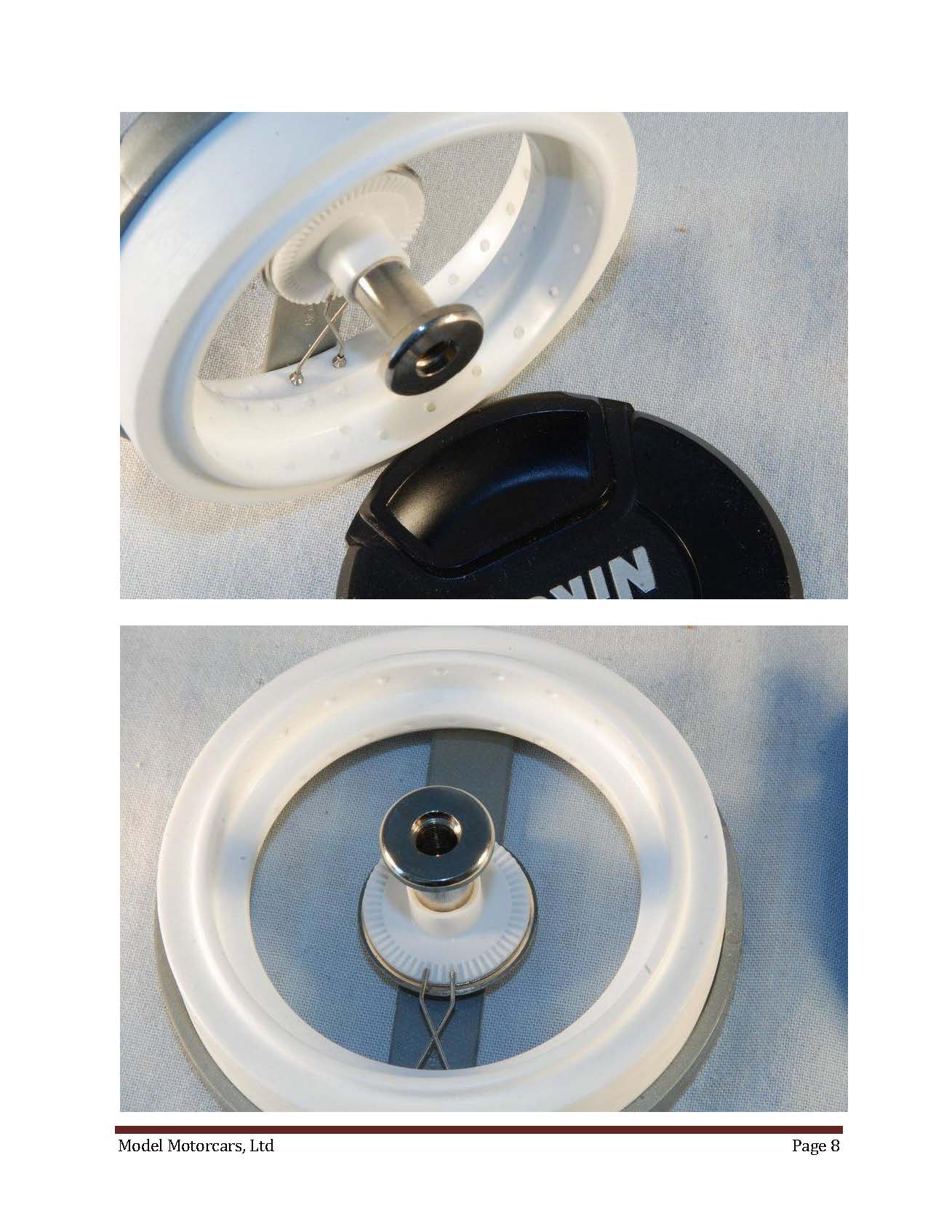

- I glued the nipples in first and then inserted the spoke end into the nipple. I then glued the center hub end into it’s slot in the spoke separator.

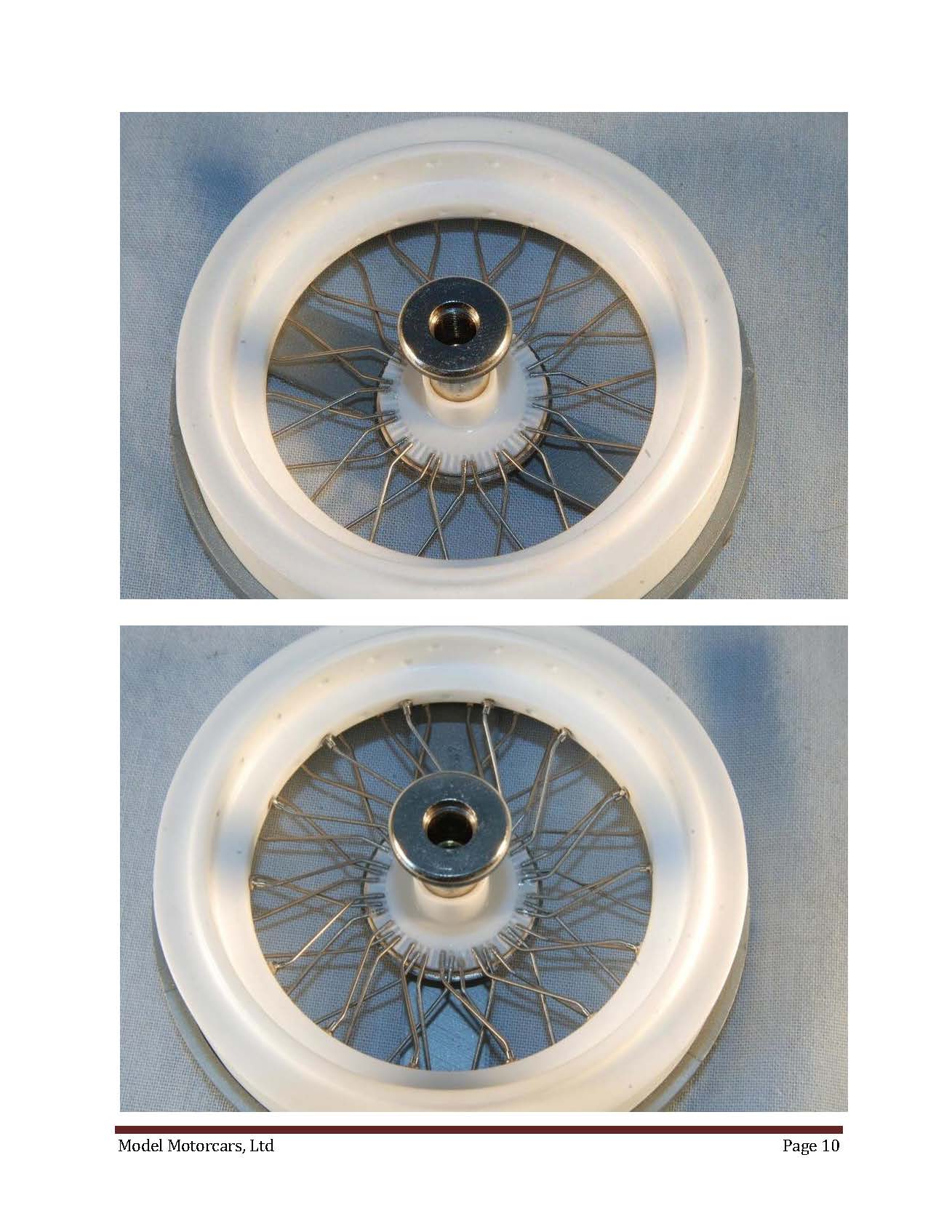

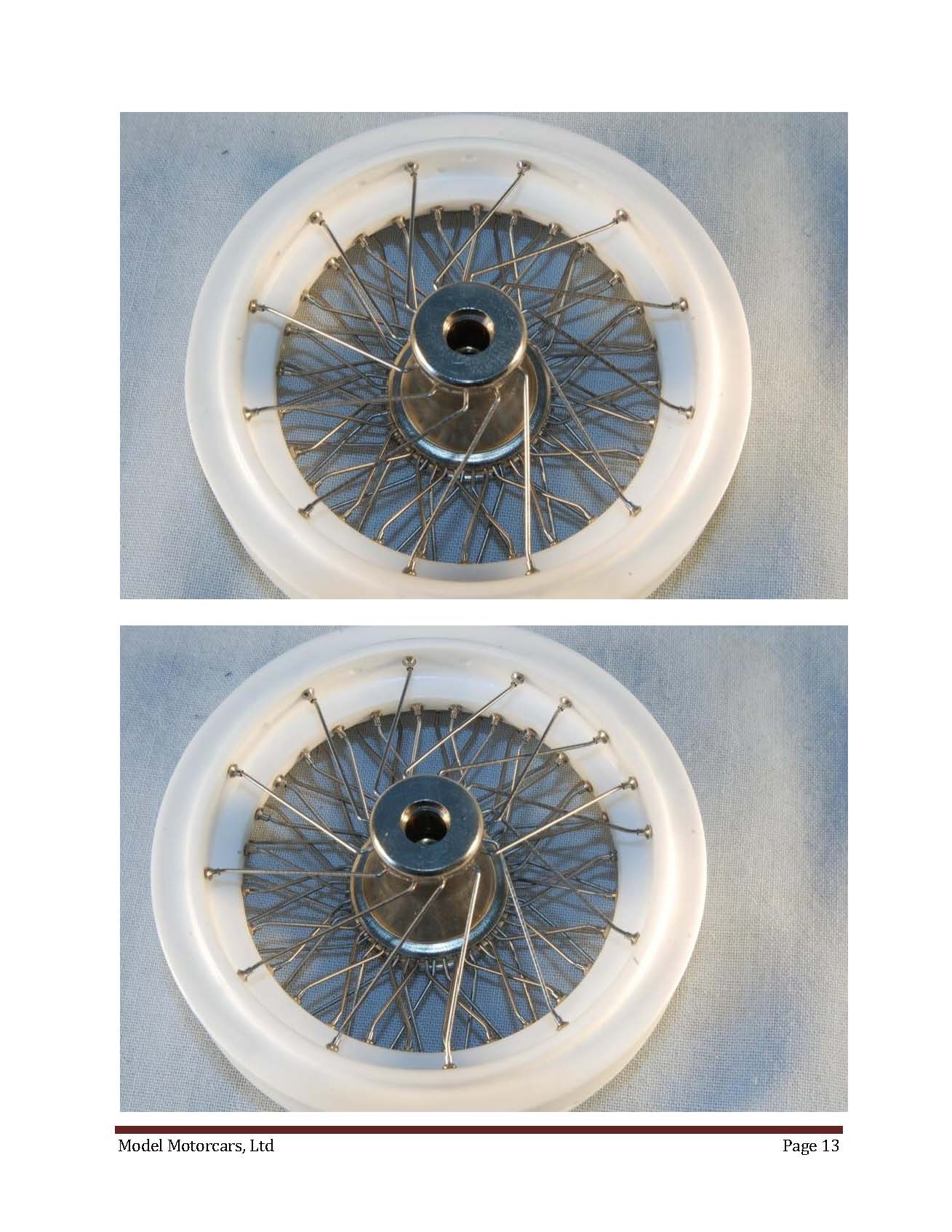

- I used Paul Koo’s DVD as a reference to help figure out what goes where. For the first row of spokes (#72053) I did two at a time and worked my way around the rim.

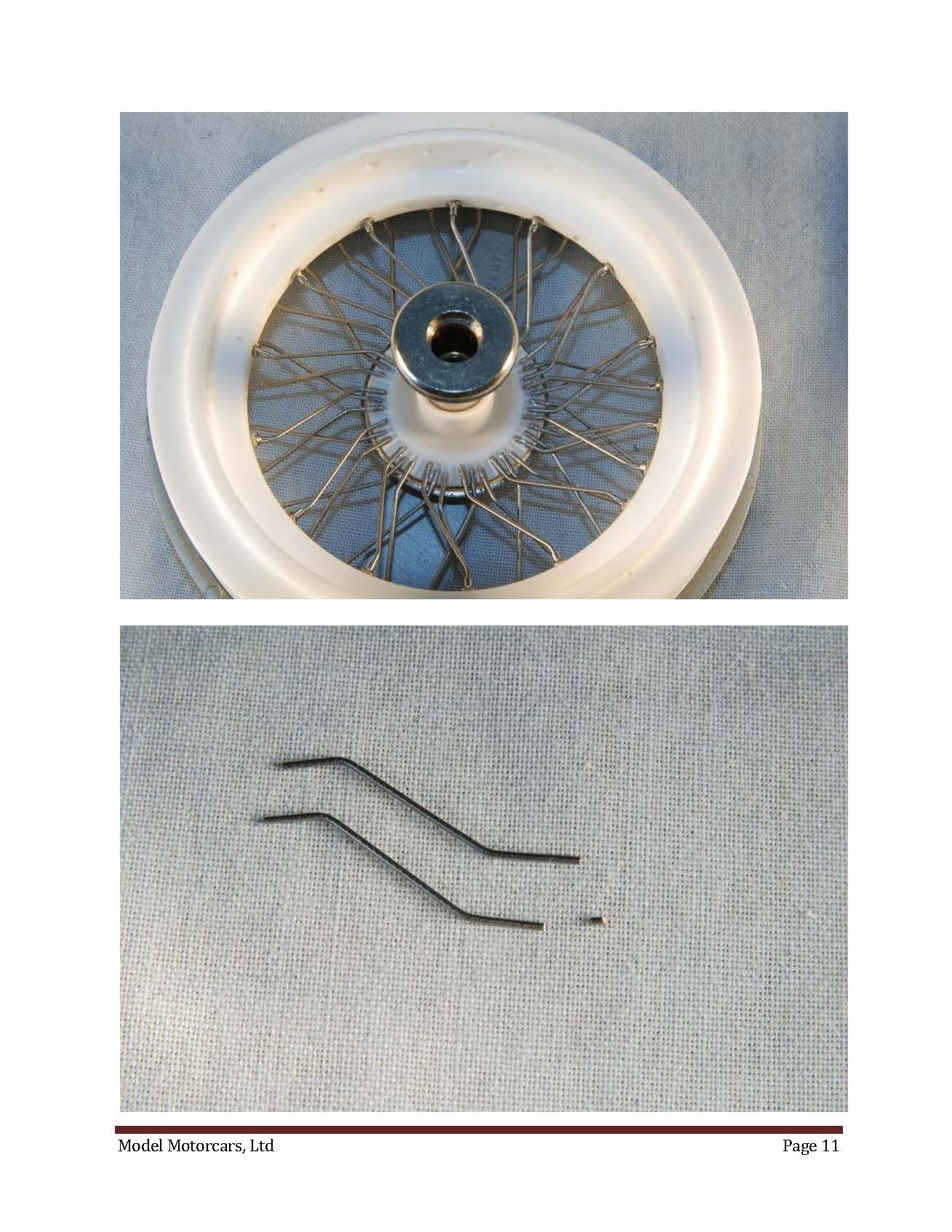

- I had to trim about 1/6” off both ends of the second row of spokes (#70254) and glued the nipple in first.

- For the second row of spokes I glued every other spoke in first and then glued in the opposite spokes.

- The last row of spokes I glued in all the spokes going one way and then the opposite ones. That way I ended up with the spokes that crossing one on another all the same. Be sure to have the spokes on either side of the air valve away from each other.

- Once done I use a fine beading wire to put a small drop of CA into the nipples which glue the spokes to the nipples and the nipples to the rim.